By 2025, Equinor may produce at least 650,000 BOED, or 35% of its total oil and gas output, using electricity from onshore plants. This is according to a new report from London-based analytics firm GlobalData that highlighted the spread of the electrification trend in the Norwegian Continental Shelf (NCS).

“Of the active offshore electrification projects that Equinor is involved in, Troll and Johan Sverdrup have avoided the largest emission volumes through electrification at over 600,000 tons of CO2 per year each,” Daniel Rogers, a senior oil and gas analyst at GlobalData, said in a statement.

He added that Equinor is “aggressively expanding” its plan to electrify several other fields, partially or entirely, in the North Sea and across the wider NCS. Equinor’s goal is to reduce its baseline emissions 60% by 2030 before achieving a nearly 100% reduction by 2050.

Equinor expects that reaching the 2030 target will cost it and its partners at least $5.7 billion. A major portion of that figure is being spent on replacing the gas- and diesel-powered turbines found on Equinor's platforms with high-voltage direct-current (DC) subsea power cables that are connected to the Norwegian electricity grid. Equinor said last year that the offshore sector's gas turbines accounted for one-quarter of Norway’s CO2 and NOx emissions.

The Trend Is Real

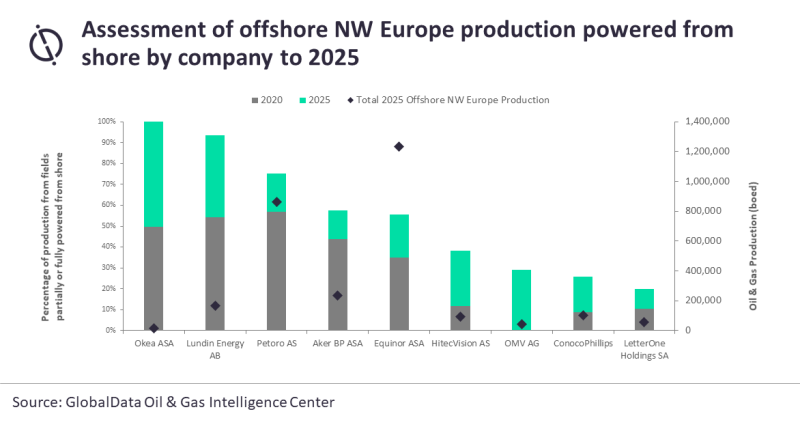

While Equnior becomes a well-established leader in the drive toward electrification, a distinction that has been years in the making, GlobalData pointed out that it is not alone.

Stockholm-based Lundin Energy will over the next 3 years achieve a 90% electrification rate of its production in the region. Trondheim-based OKEA, which focuses on mature field development, has electrified half of its production base and GlobalData predicts it could be 100% electrified by 2025.

In addition, there are at least 20 other Norwegian offshore fields being considered for electrification. GlobalData cited increasing carbon taxes in Norway as a driver behind the sustained interest among Norwegian operators. It noted, too, that while electrification has higher upfront capital costs for greenfield developments, it tends to result in improved production efficiency which strengthens the investments' long-term economics.

The Norwegian Experience

While electrification is showing no signs of slowing down offshore Norway, it remains unclear whether the drivers exist to make that happen in other offshore oil and gas regions. This was one of the key points in a technical paper presented at the 2020 Offshore Technology Conference (OTC 30898) by authors from Equinor and its partner Lundin.

Among their conclusions is that electrifying Norway’s offshore fields is “perhaps less relevant to other oil and gas basins and jurisdictions around the world” because of the nation’s cheap and plentiful supply of onshore electricity and its policy priorities regarding CO2 emissions. (It is estimated that 98 to 99% of Norway’s mainland power supply comes from more than a thousand small, medium, and large hydropower plants spread across the country.)

The paper focuses specifically on the electrification efforts at Equinor’s newest major development, the Johan Sverdrup field which came on stream in October of 2019. Located nearly 93 miles offshore Stavanger, Johan Sverdrup represents an estimated 2.7 billion bbl of recoverable oil.

The first phase of the project was completed before field startup and its centerpiece is a high-voltage cable that supplies 100 MW of power to the offshore facilities. For comparison, some of the gas turbines being used today by Equinor are rated for 30 MW. In addition to electricity, most operators also use the heat exhaust from these systems to maximize their energy efficiency.

To replace the traditional power systems efficiently has been no small feat for Equinor and has required the construction of a dedicated onshore station to convert the Norwegian grid’s alternating-current (AC) power to DC power.

The decision to use DC power was made to ensure minimal transmission loss to the field where an inverter is used to convert the electricity back to AC. By using a hub, smaller subsea power lines can then transmit AC power to nearby platforms and more distant fields.

Johan Sverdrup should be fully electrified with a second 200-MW subsea cable, supported by another onshore converter station, sometime next year. When that day comes, Equinor said each barrel's lifting cost will be around $20, and in terms of emissions, will generate just 0.67 kg of CO2.

The operator said this is about 5% of the industry’s average emissions profile for each barrel (world average is about 18 kg of CO2) and a record-low for any of its developments.

In the lead-up to the project Equinor had to work through a number of new regulatory questions and negotiate with more than a dozen operating partners and the government on how to build an offshore grid. These talks began in 2016 and would last for 2½ years before Equinor was able to sanction the electrification initiative.

Also highlighted in Equnior’s paper are the number of energy efficiencies that it executed at the Johan Sverdrup facilities. “For energy saved, there is an opportunity to use energy elsewhere and thereby reducing CO2 emissions to air further,” the authors said. Some of the changes this focus entailed included using variable speed drives on export pumps, netting an energy savings of 2 MW.

In the next phase of development, Equinor plans to remove a multiphase heating system that supports flow from satellite wells located more than 6 miles from the main platform. To ensure flow assurance without the heating unit, the flowlines will be insulated, and pipe-in-pipe technology will be used. Other measures are needed too, but by removing the heater, Equinor will increase its offshore power budget by 5 MW.

In April, Equinor shed some light on what the operating costs of its electrified oil fields may be after it awarded ABS and Siemens Energy service agreements valued at around $536 million. The contracts include 8 years of firm service and maintenance work on Equinor’s offshore electric infrastructure and is expected to involve nearly 100 man-years of work.

Outside of shore-to-offshore projects, Equinor is also investing heavily in the wind sector, some that may eventually be tied to its oil and gas developments. It is also experimenting with floating solar panels.

For Further Reading

OTC 30898 Electrification and Other Measures To Minimize Carbon Emissions from the Johan Sverdrup Field by S. Birkeland, G.Veire, C. Holm, H. Samuelsen, J. Torgersen, H. Nordang, and V. Lossius, Equinor; N. Mjølnerød, Lundin Norway AS.