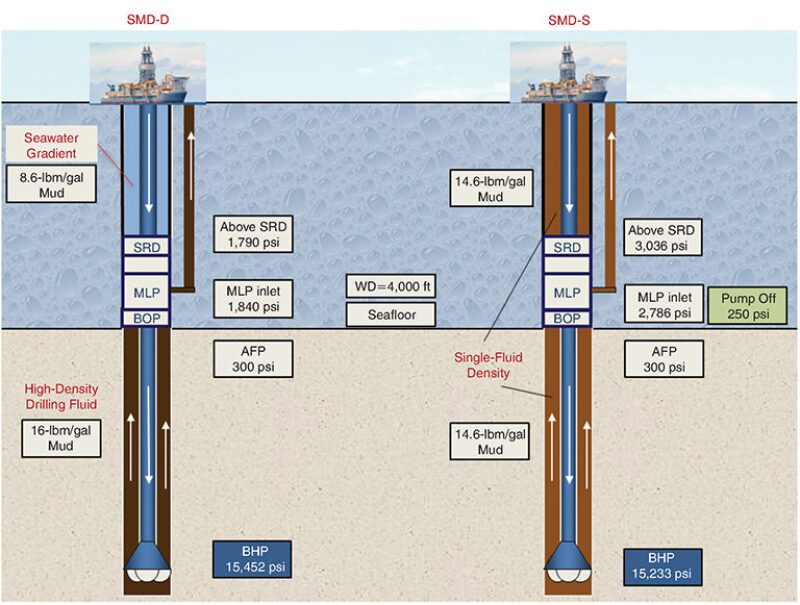

Subsea-mud-lift-drilling (SMD) technology is a form of managed-pressure drilling (MPD). As with other MPD systems, SMD technology offers early detection of influxes (kicks) and minimizes downhole losses to weak subsurface formations. However, significant differences are built into the SMD system. This paper will highlight the benefits of single-gradient SMD (SMD-S) technology, the execution of the most recent deployment, and test results that represent the final steps in moving toward continued MPD operations in the deepwater Gulf of Mexico (GOM).

Introduction

SMD is a sophisticated subsea MPD technology development and commercialization project that has just completed its fourth offshore deployment. With every deployment, the learnings have been captured and addressed successfully.