COVID-19 may lead the liquified natural gas (LNG) industry to prioritize smaller LNG projects, according to consulting group Thunder Said Energy.

Smaller plants and modular, phased designs may offer a more viable option for the industry coming out of the COVID-19 pandemic.

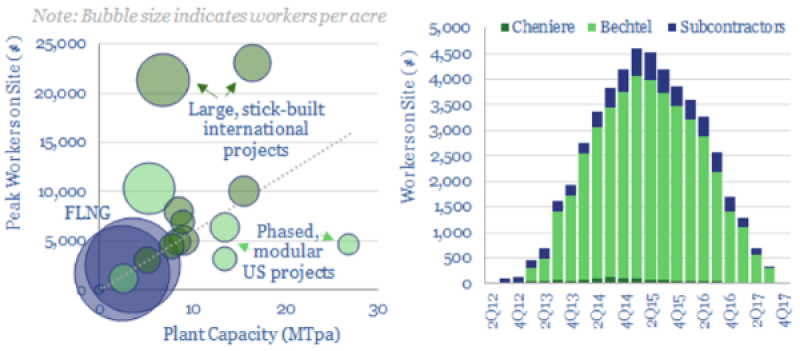

The advantages of smaller plants include a lower workforce count compared with larger LNG plants. An average international LNG facility requires 1,000 workers on site per mtpa of capacity, potentially reaching over 20,000 workers at the largest, stick-built facilities. Workers at international plants are typically housed at the project in close quarters for 2–3 week rotations, which are risky amid the pandemic.

Floating LNG (FLNG) is more compact than typical international projects, with the highest density of workers. Fitting equipment that usually takes up 100-200 acres at a typical LNG plant can take up 6-9 acres total space on an FLNG. Modules which typically have large exclusion zones are congested, requiring extremely cautious operation, which may impact economics through higher costs and lower uptimes.

In the US, LNG projects have required fewer workers by being smaller and modular in design.

For example, Cheniere’s Sabine Pass LNG had the lowest worker/capacity ratio in Thunder Said Energy’s data, reaching 27 mtpa of capacity with 4,600 peak workers. The project’s location in Louisiana also attracted local labor rather than housing expat workers on rotation.

“This distinction may matter for the future of LNG,” Thunder Said Energy said. “Upcoming international projects are generally going to be stick-built in remote locations, while upcoming US projects may be even more modular than past ones.”

The group noted smaller plants should achieve cost advantages over larger plants, and lower risk levels of US LNG projects may impact project prioritization.

A push toward smaller LNG plants may come amid a potential global shortfall of 100 mtpa in 2024–2026, brought on by delays and deferrals from COVID-19.

“A 100 mtpa shortfall [in supply] would be unprecedented, five times worse than the 2011 Fukushima disaster,” the company said. “Hence the best companies will keep making headway, ramping up gas to drive the energy transition. “

A company analysis shows the pandemic will disrupt 15–45 mtpa of supply growth, and delays will defer 15–25 mtpa of planned 2023–2024 startups. Project deferrals also cut 20–40 mtpa of startups in 2025–2027, with prices below $2.00/Mcf preventing final investment decisions.

Half of those deferrals and lack of FIDs are in the US, where Thunder Said Energy said shale downgrades have delayed or deferred 100 mtpa of associated gas.