Owners/operators today are serious about reducing the cost of capital projects. A major oil and gas company has announced that reductions of 20% to 50% from current levels of project costs are required if projects going forward are to be considered affordable. Executives of other majors have stated similar goals. There is a sense that “everything is on the table.”

Clearly, this level of capital cost reduction is not going to be achieved by “nibbling at the edges.” Cost reductions of this magnitude require a serious rethinking of the strategy for developing and executing projects.

This article presents an integrated, portfolio-level cost reduction strategy that overcomes the typical barriers to success and produces demonstrable results.

The Portfolio Perspective

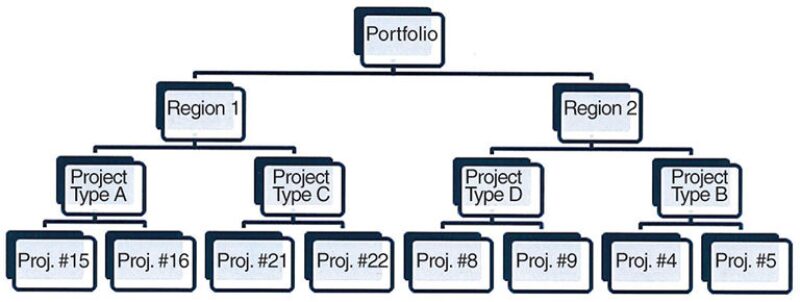

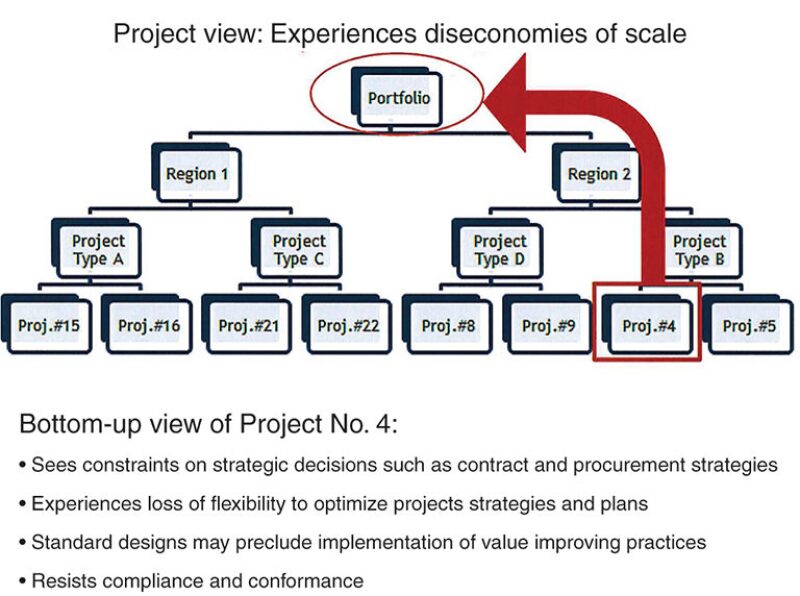

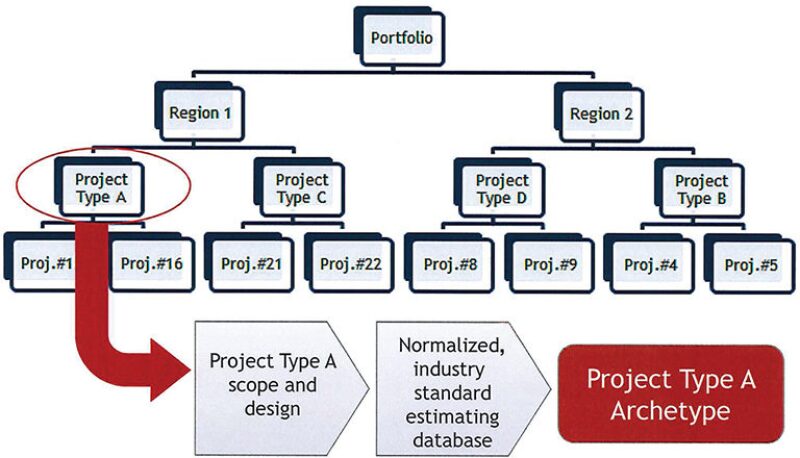

Fig. 1 provides a simplified view of a typical project portfolio and how it may be expressed in regions/business units, and by project types such as offshore (deep and shallow water), pipelines (onshore and offshore), liquefied natural gas (manufacturing and regasification), and refining (expansions and upgrades). The goal for owners/operators is to see a disciplined, systematic reduction of capital cost across the project portfolio.

The portfolio perspective provides opportunities for three well-proven cost reduction engines: standardization, economies of scale, and “experience curve” effects. Experience suggests that an effective implementation requires an integrated approach to provide synergies not otherwise available.

Standardization Methods

Although often resisted on the basis that it inhibits the flexibility needed to optimize a project, standardization has been shown to be an effective way to reduce cost across the portfolio.

The methods for standardization are as follows:

- Designs. The energy industry has long embraced the concept of “design one, build many.” This may be applied at various levels ranging from overall configurations (for example, a standard floating, production, storage, and offloading unit) to a standardization of key design elements such as a power package. It must be recognized that a standardized design is seldom optimal for any given project; however, if done right, the time and cost savings in front-end definition will be significant and will benefit the portfolio performance.

- Standards. Although many owners/operators have evolved their own standards (which are usually higher than the general industry practice) over the years, the search for cost reduction is leading to a fresh look at the application of industry standards. The standardization of standards does not preclude the use of higher standards in some cases but, in the interests of cost reduction, these should be carefully justified with realistic assessments of capital and life cycle cost.

- Work processes. Standard work processes may be applied to many areas, including project management, engineering, procurement, contract administration, and construction activities. The cost-reducing benefits of standardization may be easily lost when work processes become too complex. Standardized work processes must be carefully tested to assure that they add value.

- Contracts. Standard contracts, terms, and conditions may reduce the time and cost of contract negotiation and the contractor’s risk premium.

The key to cost reduction is to take a holistic view of standardization with the goal of synergizing the efforts. For example, standardized designs using industry standards may enable more efficient work processes for both owner and contractor, resulting in lower contractor costs and improved commercial terms. Standardization does not only reduce cost, but it also improves efficiency, predictable outcomes, and operational reliability.

Economies of Scale

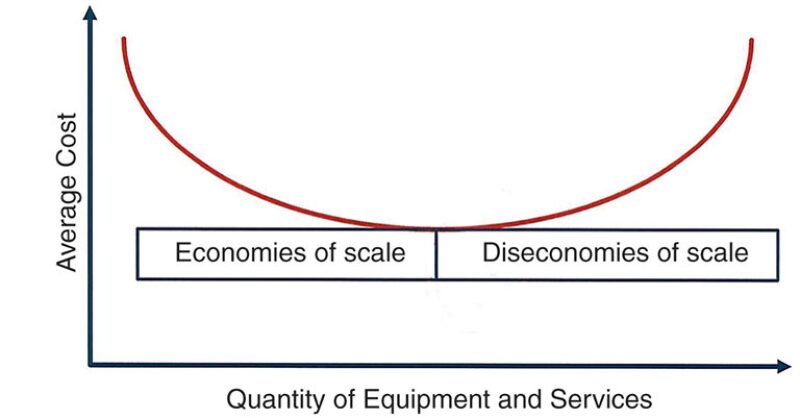

Standardization enables a greater opportunity for achieving economies of scale across the project portfolio by leveraging portfolio synergies with the procurement of engineered equipment, bulk materials, and engineering and construction services. Fig. 2 shows the classic view of economies of scale.

Care must be taken to avoid diseconomies of scale. For example, large volume purchases of engineered equipment attract competitive pricing and major discounts, providing economy of scale. However, diseconomy of scale may result if one goes to the market with a large volume purchase and insufficient lead time or if a megaproject has requirements that are large enough to change conditions from a buyer’s market to a seller’s market.

The integration of standardization with economies of scale is important, because the more standardization that is in place, the easier it is to plan large volume purchases across the portfolio.

Experience Curve Effects

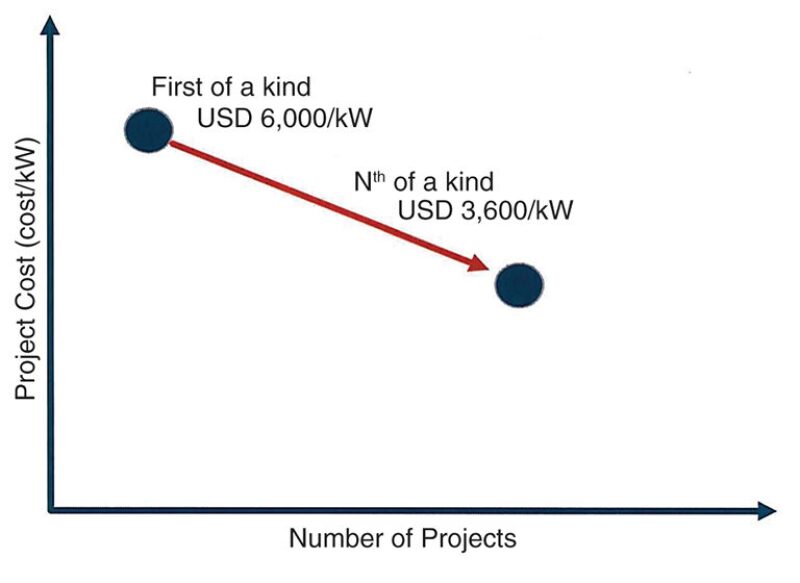

The “experience curve” is a long-standing illustration of the significant savings to be gained through repetition (Fig. 3). A project-related example of the cost effect of the curve on major projects may be found in the nuclear power industry. A study of power generation costs by the UK Department of Energy and Climate Change (MacDonald 2010) revealed a 40% overall cost reduction from first of a kind designs to Nth of a kind (NOAK) as a result of standardization.

The integration with standardization is critical; the more the designs and work processes are standardized, the more projects become NOAK and the more opportunities exist for cost reduction through repetition.

Why Cost Reduction Initiatives Fail

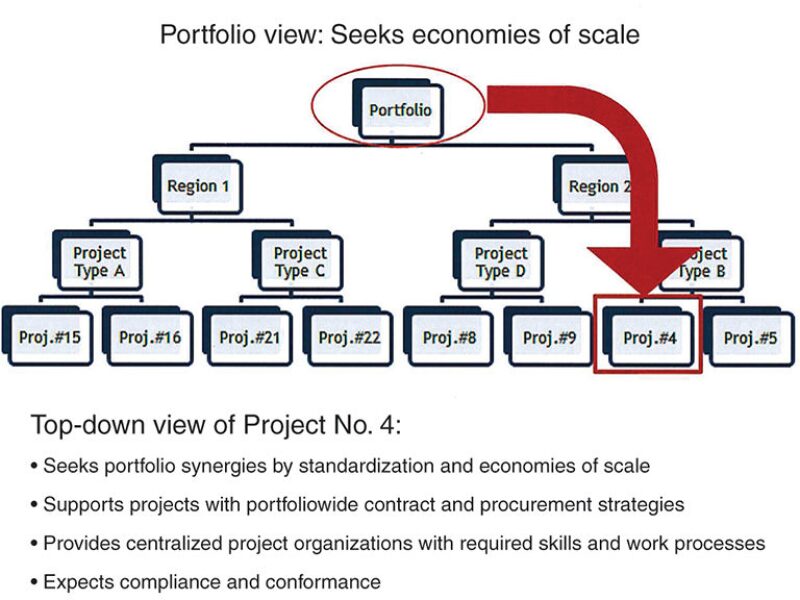

In spite of the apparent benefits of a portfolio approach to leverage standardization, economies of scale, and the experience curve, such top-down initiatives are often ineffective. Figs. 4 and 5 illustrate some of the mind-sets and behaviors at the portfolio and project levels that may turn economies of scale to diseconomies of scale.

From the portfolio perspective, projects are being empowered and enabled to reduce cost. Key decisions, in areas such as contract and procurement strategy, may have already been made at the portfolio level through alliances and long-term agreements. Work processes have been defined and specialists in the central organization, such as project managers, are available to support the project in implementing them.

From the portfolio perspective, project managers and teams, such as on Project No. 4, should be grateful for the support.

However, from the project perspective, things look quite different. The project manager is being held accountable for how well the project performs. She may not appreciate having so many key decisions about the management of the project being made by others, or having to justify to a central organization why and how she does what she does. Her perception may be that though she is accountable for the results of the project, key responsibilities and decisions are being imposed on her.

Since it is unlikely that she is equally accountable for the performance of the overall project portfolio, the arguments that conformance to portfolio standards will help the company overall are likely to be unconvincing.

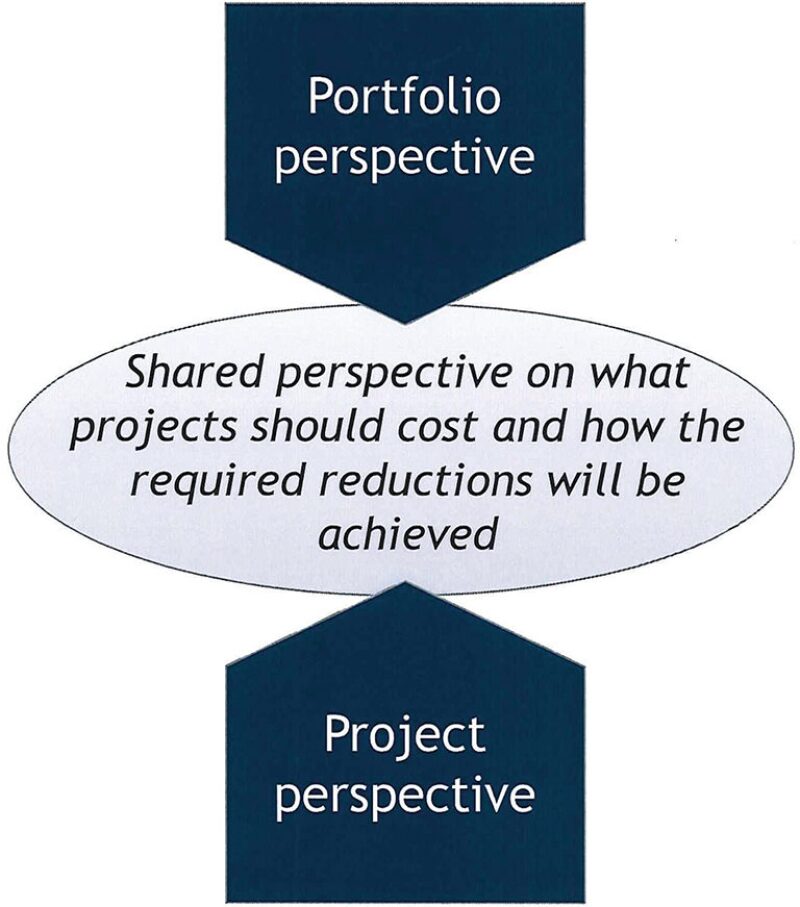

Leadership at Portfolio and Project Levels

A way to align leadership at the project and portfolio levels is needed to understand how cost reductions are to be achieved and what each person should do to achieve them. Cost reduction must be aligned with the key business drivers behind the capital expenditure program; these should be well understood at both the portfolio and project levels. The key is a shared perspective (Fig. 6).

This shared perspective requires a specificity about what a project should cost and the cost reduction strategies and levers that may be applied to achieve the objective.

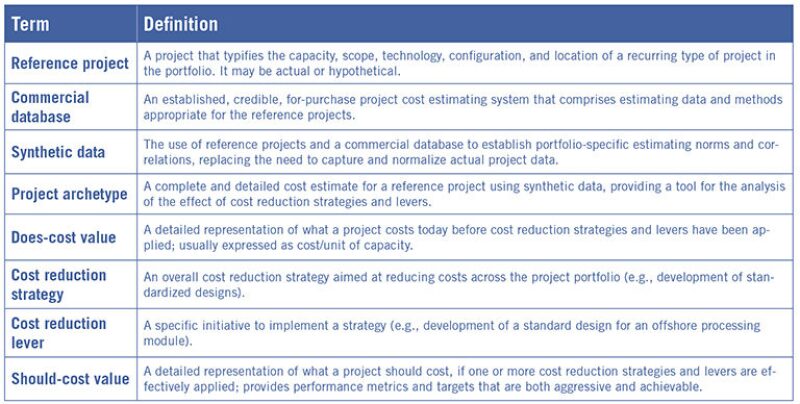

A should-cost analysis tool is a straightforward way to develop a detailed picture. The methodology requires an understanding of the terminology defined in Table 1.

Development of a Should-Cost Analysis Tool

The goals of the should-cost analysis tool are to provide a means to gain an improved understanding of the key drivers of project cost, facilitate the process of developing cost reduction strategies and levers, assess the potential cost reductions associated with strategies and drivers (both individually and integrated), and define a cost reduction implementation plan and set cost reduction targets accordingly.

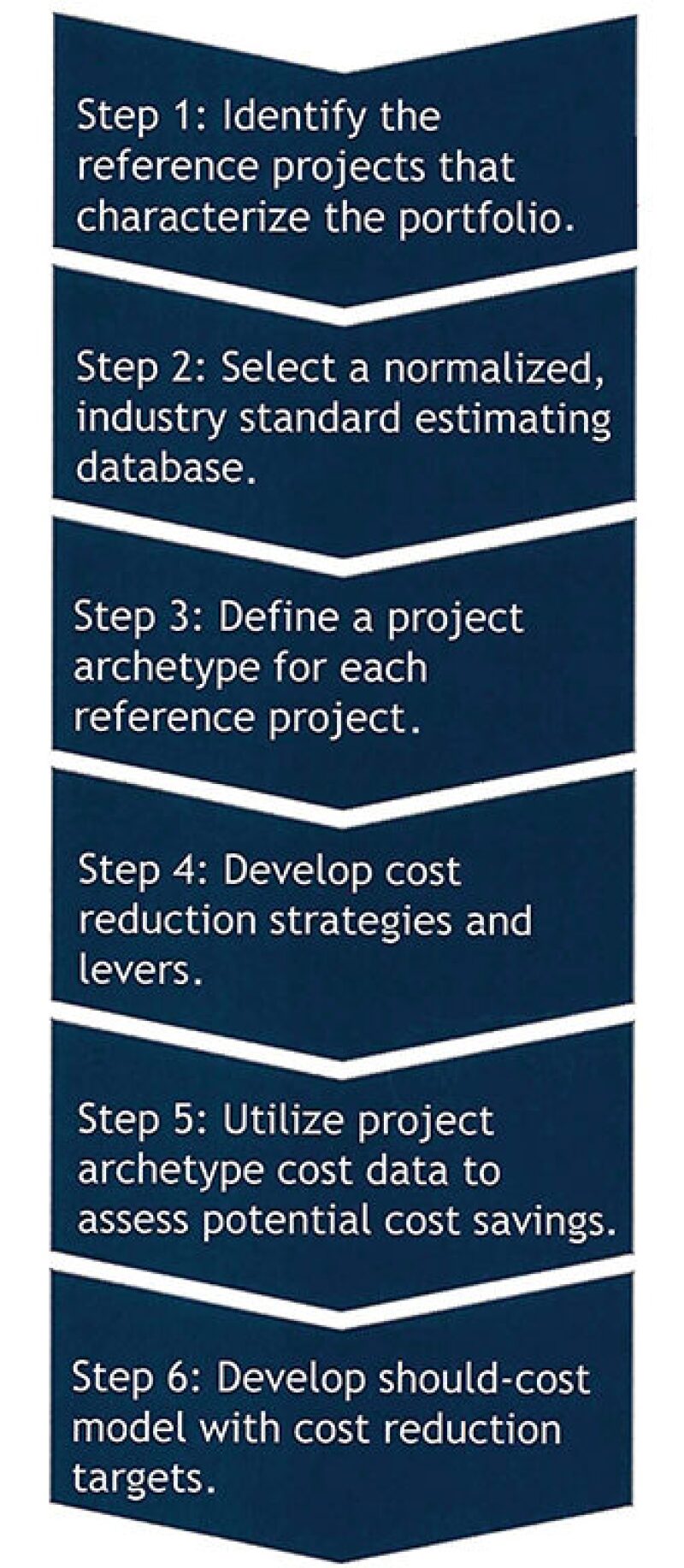

The steps for developing the tool are shown in Fig. 7.

Step 1: Identify the reference projects that characterize the portfolio. These reference projects may be characterized as those for which cost reduction is considered a particular priority, because they represent a considerable portion of the portfolio and/or are perceived as having excessive costs.

Step 2: Select a normalized, industry standard estimating database. The benefits of the use of a commercial database are as follows:

- Most owners lack the amount of project data needed for an analysis and statistically significant inferences about the cost of future projects.

- The use of actual project data requires normalization for time, location, scope, technology, and other variables. This difficult process is precluded by the use of a commercial database.

- Commercial estimating databases generally provide flexibility to account for project specifics such as location and scope.

- Commercial estimating databases are continuously updated for current pricing and market conditions.

- Commercial estimating databases are typically accessed through a Web-based interface, making it easy to use and share information.

Step 3: Define a project archetype for each reference project. The scope, design, and planning parameters that define each reference project are used as input to the commercial estimating database so that a complete, detailed estimate is developed. This is the archetype for the reference project. It provides synthetic data for cost analysis: data that is not based on the owner’s actual projects, but on an accepted representation of actual project cost. Steps 1, 2, and 3 are shown in Fig. 8.

The project archetypes now provide a reliable, consistent, and realistic basis for assessing the potential effect of cost reduction strategies and levers.

Step 4: Develop cost reduction strategies and levers. The project archetypes may be used to develop an improved understanding of where the greatest opportunities for cost reduction lie and provide the basis for developing broad strategies and levers for implementation.

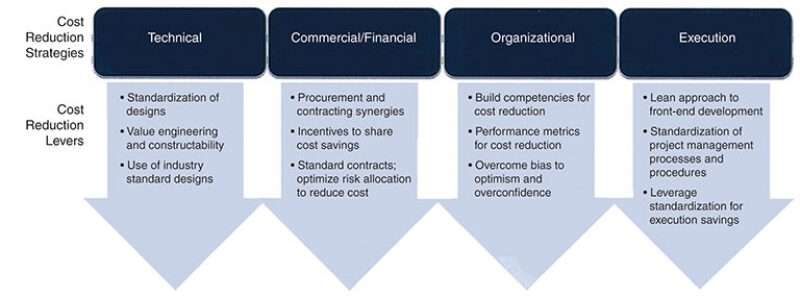

Fig. 9 shows how strategies may be associated with the primary dimensions of a project: technical, commercial/financial, organizational, and execution. These dimensions must be considered in an integrated way. For example, the organization must be configured to effectively execute projects based on technical and commercial/financial strategies and levers.

Step 5: Use project archetype cost data to assess potential cost savings. The project archetypes provide the estimating data and methods to assess short- and long-term effects of strategies and levers. These may be analyzed on the assumption that they are acting alone, or (even better) as part of an integrated approach.

Step 6: Develop should-cost model with cost reduction targets. The should-cost model provides a detailed, credible picture that brings together the project portfolio, cost reduction strategies and levers, and realistic cost data into a comprehensive plan for cost reduction.

Summary

Everyone agrees that capital project cost needs to be significantly reduced if the economics are to be sufficiently sound to support investment, yet step changes in project cost are difficult and, in fact, seldom achieved.

This article has presented an integrated, top-down approach that aligns project teams with portfolio strategies and provides the basis for the detailed analysis and metrics needed to manage performance. The cost engineering concepts used to create a should-cost model have been in use for decades and are even more effective today, thanks to the evolution of commercial estimating databases and systems. Leadership is required if cost reduction programs are to show results, and the integration of the technical, commercial/financial, organizational, and execution engines is where it is best focused.

For Further Reading

MacDonald, M. 2010. UK Electricity Generation Costs Update. (accessed 17 March 2015).

Richard (Dick) E. Westney founded Westney Consulting Group in 1978, after having managed international exploration and production, refining, and petrochemical projects for Exxon. He is the author/coauthor of five books and has served as visiting faculty for construction executive programs worldwide. Westney is a fellow and past president of the Association for the Advancement of Cost Engineering and a licensed professional engineer and certified project management professional. He is a graduate of the City College of New York, Rensselaer Polytechnic Institute, and Harvard Business School. He may be reached at r_westney@westney.com.