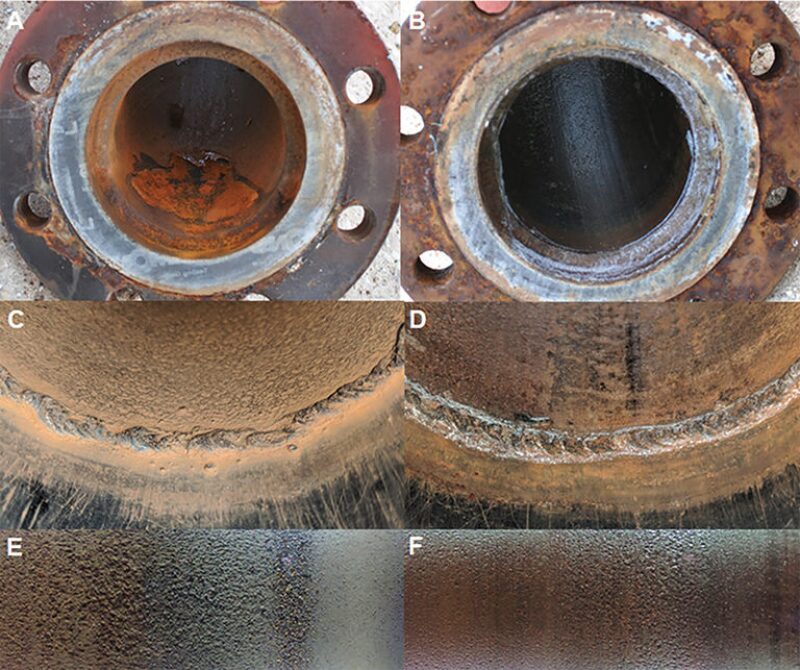

This paper describes a material designed to interact specifically with highly corroded and weathered pipe to enable in-place application and refurbishment. The material is applied extremely thinly on the pipeline interior, such that it might be considered a surface treatment, yet it is designed for permanence and for strong adhesion to even severely corroded surfaces. The water- and oil-compatible, chemically resistant material shows extreme resistance to corrosion, particle abrasion, and delamination under operational conditions, and is designed to reduce surface roughness by several orders of magnitude. The study of the practical effects of using a low-surface-energy, low-surface-roughness coating that can be applied effectively to severely corroded pipelines with a minimum of surface preparation demonstrates how material breakthroughs can allow for revitalization of previously mature intervention techniques.

Introduction

Improving flow efficiency within transport pipeline systems has always been an appealing and seemingly straightforward method of reducing operating expenses, improving product throughput, and significantly reducing the risk of catastrophic pipeline failure.