Congratulations to SPE’s Journal of Petroleum Technology (JPT) on its 75th anniversary. This milestone presents a good opportunity to look back on SPE’s longstanding commitment to promoting a safe, healthy, environmentally friendly, sustainable, and secure workplace for everyone working in the oil and gas industry, both onshore and offshore. As I prepared to write this article, I reread a guest editorial I wrote for JPT after the 2012 SPE International HSE Conference and Exhibition focused on “The Growing Importance of HSES-SR in Our Industry.”

The good news is that SPE has remained active in promoting conferences and workshops as well as enhancing competencies across the spectrum of HSE subdisciplines. Challenges remain, however, in engaging functional leaders across our industry and achieving more consistency related to industrywide HSE culture, leadership, management systems, risk management, and sustainable development.

Another historical challenge facing our industry continues to be how to learn from the past and more effectively share lessons learned in HSE with the objective of pursuing continual improvement in all we do. A strength of SPE has been, and continues to be, the ability to convene and leverage the expertise of our global members and sister organizations in achieving this objective, as well as identifying and developing innovative, engaging, and sustainable approaches to turn this objective into a reality.

My goal in this article is to share with you some of the HSE accomplishments we’ve had over the past several years in this industry, as well as what the future might hold. Unfortunately, given the breadth of the HSE discipline, it is not possible to do adequate justice to the large number of proactive initiatives pursued by SPE over the past several years, so I’ve tried to highlight a handful of those items I felt were most impactful as a result of SPE engagement.

Background

SPE hosted its first international HSE conference in 1991 and has held numerous international and regional conferences ever since. As evidence of SPE’s recognition of the importance of HSE to oil and gas activities, the first technical directors were added to the SPE Board of Directors in 2001, with the role of HSE technical director established in 2002. The scope of the HSE role was expanded to include security and social risk management in 2007, and sustainable development was added in 2014.

From 2010 to 2014, I was privileged to serve as the fourth HSE technical director on the SPE Board of Directors. I want to thank my predecessors in that role for establishing a strong HSE foundation on which to build, and I hope I was able to do the same for my successors. My exposure to the global HSE community within SPE allowed me to more fully recognize the extent to which HSE crosses all discipline boundaries, as well as the extent to which HSE affects other parts of the oil and gas industry and more broadly other industries. It is important that we continually look outside our normal boundaries so that we can learn from one another, as well as share all of the great initiatives SPE and its members have developed on the upstream side of the business.

The oil and gas industry has always been focused on HSE excellence; however, there have been some defining events that have served to remind us of the high-risk nature associated with our industry. Some of the major events affecting the way we do things today include Piper Alpha (July 1988), the Exxon Valdez spill (March 1989), and the Macondo Deepwater Horizon (April 2010). These events all served to highlight and emphasize the importance of the following HSE focus areas:

- The importance of a strong and sustainable HSE culture

- The development and implementation of structured safety and environmental management systems

- The role of an effective management-of-change program that encompasses all aspects of an oil and gas asset’s life

- The benefits of industrywide data sharing to identify trends of concern and learn from the past

- The importance of working with regulatory authorities to ensure that regulations support continual improvement in all aspects of HSE

Important regulatory reforms targeting HSE improvements were adopted following the Macondo disaster and mandated safety and environmental management systems (SEMS) intended to avoid repeating the organizational and management lapses that led to Macondo. Also adopted were regulations targeting technology such as tightened regulations for well control and production safety systems. The industry also created the Center for Offshore Safety (COS), which focuses on SEMS implementation and assessments. Industry and government have collaborated on improved near-miss and other safety-indicator data collection and sharing designed to inform decision-making about systemic risk management, with one objective being to transition from over-reliance on lagging indicators to more effective and consistent leading indicators. I’m happy to note that SPE has been actively engaged throughout all of these changes to promote dialogue related to effective implementation.

Role of a Strong and Sustainable HSE Culture

The lessons learned from the Piper Alpha disaster were numerous and reach far beyond the offshore oil industry, across all hazardous industries, and are every bit as relevant today. Key among these findings was the lack of an effective safety culture, which fostered the belief that everything was fine, as well as several deficiencies in the management of change, process safety, internal communication processes, and emergency response procedures. Before the Macondo disaster, many in the industry found it difficult to imagine an accident in the US that would result in a major oil spill, loss of lives, injuries, and the sinking of a rig. This then led the National Academies of Science, Engineering, and Medicine to convene an expert committee to identify ways in which the offshore oil and gas industry, government, and other stakeholders can strengthen the industry’s safety culture. The report and its companion summary, “Beyond Compliance: Strengthening the Safety Culture of the Offshore Oil and Gas Industry,” were issued in 2016.

On a more recent note, you may recall a Japan Airlines crash and explosion on 2 January 2024, where all 379 passengers and crew aboard the aircraft survived. This accomplishment was attributed in large part to the positive effect of a strong safety culture and good training and the benefits of applying lessons learned. The airline recognized that something going wrong presents an opportunity to view the situation in terms of how it can learn. It also recognized that many employees were joining the company without a memory of prior accidents, so understanding how much effort goes into maintaining an effective safety program was important. Sound familiar? I found this airline incident to be a great reminder of the importance of a strong safety culture and the need for continuous reinforcement of the principles and management commitment.

The importance of a strong culture has been the focus of several industry organizations such as SPE, the COS, the Offshore Operators Committee (OOC), the American Petroleum Institute (API), the International Association of Drilling Contractors (IADC), and the International Association of Oil and Gas Producers. SPE has actively worked, and continues to do so, with all of the aforementioned organizations and other experts in promoting discussion around establishing and embedding an effective safety culture as part of its various international and regional HSE conferences globally.

The day that the industry feels it has achieved its objectives in the area of safety culture should be a warning sign to everyone that more needs to be done to ensure that the culture is sustained as all companies, regardless of size or global scope, go through their normal organizational and staffing changes over the years. As stated by Capt. Chesley “Sully” Sullenberger following his safe landing of a commercial jet on the Hudson River in 2009, “Safety can no longer be defined solely as the absence of accidents.”

Importance of Safety and Environmental Management Systems

A prerequisite for effectively addressing HSE program requirements in our operations is first to have in place structured management systems that provide for continuous and visible management commitment and leadership throughout the organization, from the most senior management level to the operations, project, or office worker. All oil and gas companies, regardless of their scale or where they operate, must establish a clear and consistent vision for developing HSE management systems, along with related processes, programs, and tools to enable the organization to safely explore, develop, and produce oil and gas resources in a manner compatible with the balanced environmental and economic needs of the communities in which they operate.

The establishment of structured and disciplined management systems provides a mechanism for guiding the standardized execution and improvement of HSE processes, with one of the most significant being the expectation for management to visibly demonstrate leadership, commitment, and accountability for HSE system implementation and performance throughout the life cycle of the asset. Individual roles and responsibilities also must be clearly established, accepted, and exercised, with each individual having a sense of personal accountability for items within their sphere of influence.

The API first published its Recommended Practice 75 in May 1993 to provide consistent guidance to the oil and gas industry on how to develop management programs that were designed to “promote safety and environmental protection” during operations. Recognizing that the industry has evolved, technology has advanced, and operations have changed and understanding that management systems and human performance have progressed, the API continued to enhance RP 75 and most recently issued the fourth edition in 2019. Implementation of SEMS principles was initially voluntary for operators working in the Gulf of Mexico; subsequent to the Macondo disaster, however, the US Bureau of Safety and Environmental Enforcement (BSEE) promulgated rules making the development and implementation of SEMS mandatory.

SPE remains active in promoting SEMS development and compliance at its various international and regional events with the objective of leadership, management of change, emergency response, risk management and assessment, and facility design, among others.

The Drive To Achieve Zero Safety Incidents

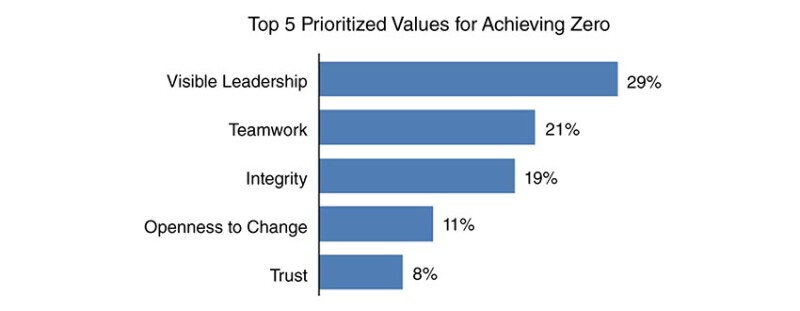

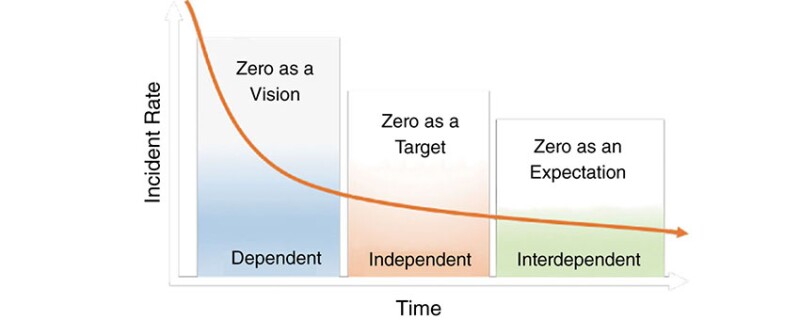

From 2009 to 2016, SPE facilitated a series of global sessions on the advancement of HSE in oil and gas. More than 850 leaders from various disciplines contributed to the discussion. The work effort culminated in a workshop at the 2016 SPE International HSES Conference in Stavanger, followed by the issuance of a report, “Getting to Zero and Beyond” (Fig. 1). SPE industry experts managing this effort were tasked with identifying a path to achieve a step change in performance focused on the expectation of zero harm (Fig. 2). The discussion of the importance of human factors included the factors that influence the interaction of people with one another, with the facilities and equipment, and with the management systems and working practices used to organize and manage the way work is carried out within the industry.

The report concluded with the following recommendations:

- Define a safety vision in which zero is an attainable expectation today, not a future goal

- Learn from other industries that are mature in human factors

- De-emphasize lagging performance indicators and use more leading indicators

- Ensure a progressive and preventative focus on the effectiveness of safeguards and risk reduction

- Establish a no-risk-to-sharing culture across the industry with the intent to overcome perceived risks and competition barriers

- Remove barriers to open sharing of lessons learned from major safety events, as well as those executed without incident

- Collaborate with regulators about risk-management strategies

- Realize an interdependent HSE culture demonstrated by a commitment to a collaborative environment and consistent safety culture

- Ensure sustainable HSE leadership and achieve operational ownership of HSE

SPE remains focused on identifying ways to turn these recommendations into action. Included among these steps are promoting Getting to Zero-type panel discussions and papers at SPE conferences and workshops, including at non‑HSE technical events, and maintaining its Human Factors Technical Section as a way to actively engage members globally.

Another important collaboration occurred when SPE partnered with the National Academies Gulf Research Program’s Safer Offshore Energy Systems Summit in May 2018 that identified a large number of follow-up ideas aimed at improving overall offshore safety performance. Participating organizations included COS, OOC, IADC, BSEE, and the US Coast Guard.

Process Safety Risk Reduction

On the process safety front, SPE recognized a gap in the scope of its HSE activities as it related to process safety and held a 2017 workshop to conduct a process safety gap analysis. The American Institute of Chemical Engineers’ Center for Chemical Process Safety was invited to participate given its long history and technical credibility in this discipline. The workshop was designed to gain a better understanding of all process safety work that was underway by various organizations with the objective of identifying areas of overlap and perceived gaps of interest for SPE members.

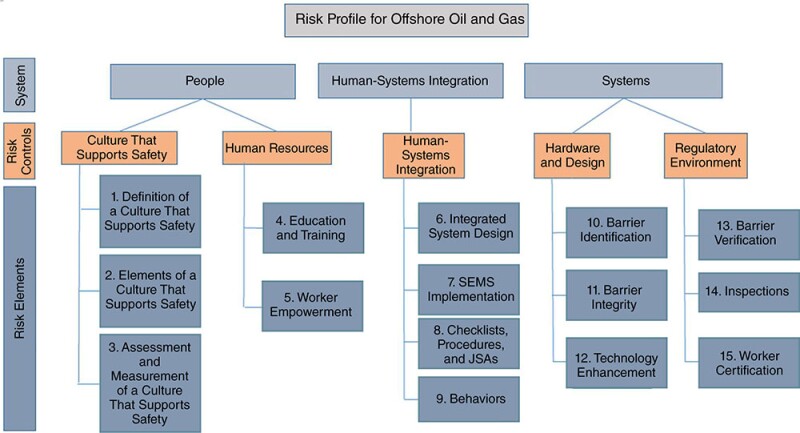

At the 10th anniversary of the Macondo disaster, the Gulf Research Program established a study group focused on “Advancing Understanding of Offshore Oil and Gas Systemic Risk in the US Gulf of Mexico.” This group was tasked with defining the current profile of systemic risks offshore, including an assessment of how changes over the years have contributed to increasing or decreasing systemic risks since Macondo.

A key outcome included in this report is the “Risk Profile for Offshore Oil and Gas” (Fig. 3), which highlights 15 risk elements that contribute to an effective systemic risk management program. Each of these areas represents an opportunity for SPE to collaborate with the Gulf Research Program and other organizations to develop workshops and training to promote a better understanding of the concept and identify actionable steps for companies, both onshore and offshore, recognizing that individual companies will be at different maturity level for each element.

Value Proposition for Industry Data Sharing

One of the initiatives resulting from the Macondo disaster was development of an industrywide framework to capture and analyze safety data from all companies operating in the Gulf of Mexico. This initiative stemmed from SPE’s efforts to partner with BSEE on a summit in April 2016 to discuss the benefits of sharing key safety data among companies with the intent of flagging trends of concerns and prospective mitigative actions.

SPE issued a report on the summit findings in September 2016. This summit included representatives from non-US oil and gas regulators, as well as representatives from other industry sectors such as aviation. The concept of industrywide HSE data sharing was supported by several HSE organizations, including the International Regulator’s Forum, which reported at the conclusion of its Global Safety Forum in June 2018 that “The opportunity for the next step change in safety performance appears to be in a substantial increase in the sharing of data across industry. Leading practices in other industries (i.e., transportation) may be adopted in the oil and gas industry to similar effect … .”

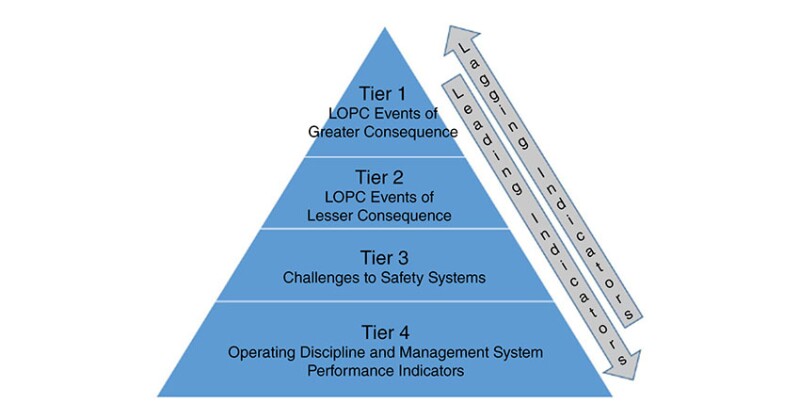

A key outcome from the SPE/BSEE summit was development of a pilot safety data management framework named SafeOCS, which was funded by BSEE and managed by the US Bureau of Transportation Statistics (BTS), a neutral third party that collects and reports data that operators share voluntarily on incidents associated with their activities. SafeOCS is intended to focus on near‑miss and significant observation data residing in the lower half of the traditional safety triangle (Fig. 4) to identify those safety events where a difference set of circumstances could result in a near miss transitioning to an injury or, even worse, a fatality.

Details on the SafeOCS program are provided in the BTS report issued in October 2019. A good activity for SPE is to identify opportunities for industry to use aggregated industry data to develop effective leading indicators.

Sustainable Development Planning

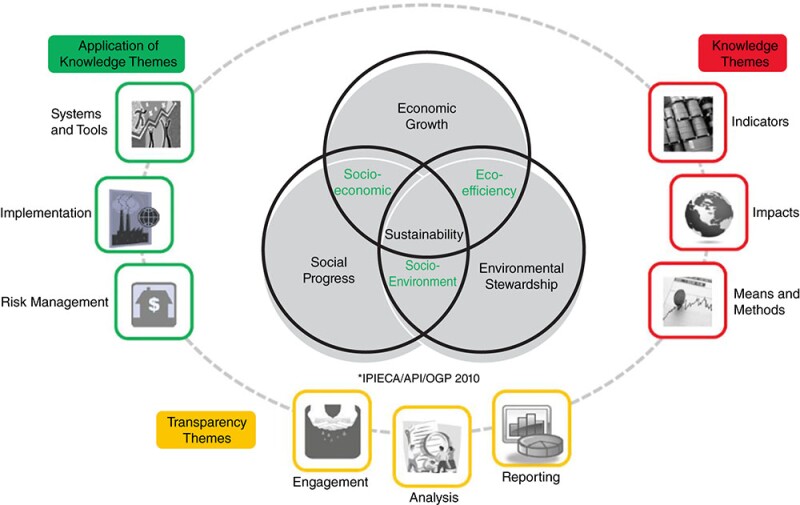

Sustainability, nontechnical risk, environmental and social performance, as well as corporate (social) responsibility are interrelated terms that refer to an important set of competencies viewed as increasingly strategic in value for the oil and gas industry. Securing and maintaining license to operate extends well beyond legislative and regulatory permitting to encompass both the mitigation of adverse social and environmental effects as well as the advancement of financial, societal, and environmental benefits via the execution of strong sustainability performance. Given the increasing prominence of sustainability for the oil and gas industry, SPE embarked on a path in 2010 when it created a Sustainable Development Task Force to explore SPE’s role and strategy in addressing sustainability, propose a methodical approach to sustainability for our industry, and participate in global sustainability discussions. In 2014, the SPE Board approved and adopted SPE’s definition of sustainable development (Fig. 5).

The HSE discipline then developed a business plan that addressed how this key strategic topic could be implemented for the benefit of SPE’s members worldwide. The overarching near-term objectives included accelerating the integration of sustainability elements across the life cycle management systems and operations of oil and gas activities, promoting performance improvements in sustainability within the upstream oil and gas industry, spotlighting best practices and facilitating deployment of lessons learned across SPE, and building a framework to support individual and corporate capabilities on existing and emerging sustainability topics. Related to the latter objective, SPE then focused on competency development plans as the optimal way for SPE to integrate these principles across industry globally. The importance of this program can best be summarized by feedback received by one of our members, who said, “You can have the best technical people in the world, but, if you don’t have sustainability covered, you probably don’t have a project.”

Among SPE’s current efforts in this area, the HSE discipline continues to further progress plans related to the SPE GAIA Sustainability Program, which was created to enable individuals in our industry to act in the service of sustainable socioeconomic development through their professional societies. As stated on SPE’s website, the objective is to empower those at all levels within organizations to create actions to address the planet’s sustainability challenges.

Communicating and Sharing Best Practices and Lessons Learned

As noted earlier, one of the key challenges for the industry as a whole is the dissemination of information and sharing lessons learned. In addition to addressing these topics as part of the many SPE conferences, workshops, and forums, as well as topical videos on SPE Energy Stream and HSE-related articles in JPT.

SPE launched its HSE Now digital publication in 2013. This publication is intended to capture technical information affecting the health, safety, security, environment, social responsibility, regulation, and quality aspects of the upstream oil and gas industry. To encourage sharing pertinent information from sources outside of the oil and gas industry, the decision was made to place HSE Now outside the SPE firewall to allow members and nonmembers alike to access the information.

Power of Collaboration

As noted earlier, one of SPE’s key’s strengths is its ability to convene gatherings of experts to discuss topics of general interest to the industry, as well as collaborate with other organizations and societies to leverage learnings from other industry sectors facing similar challenges. Several areas of commonality exist among all sectors, including personnel and process safety, risk assessment and management, and the use of management systems and data analysis to guide decision-making. Also, recognizing that most safety and risk management practices are not proprietary, opportunities exist for industries, government, and universities to work together to share experiences, case studies, and best practices across sectors so that successful approaches can be applied to different industry settings to improve safety performance. It, therefore, will be very important for SPE to continue its efforts to collaborate or partner with other organizations and societies to share best practices and lessons learned with a broader audience both internal and external to the oil and gas industry.

The Way Forward

As HSE challenges continue to emerge, the question we must ask ourselves is whether we, as an industry and as integrated organizations, are prepared to meet these challenges. How do we prepare for the foreseeable future, and what do we need to do to prepare for the unknown challenges that lie ahead? This is where SPE can play a role.

As an industry, we need to focus on our license to operate, its scope and resulting expectations, and how to earn and protect that trust. All aspects of this industry have a vested interest in getting it right, because what happens to one company essentially affects everyone. We see lots of new faces working in the oil and gas sector because of retirements; it is crucial that SPE continues its efforts with the objective of keeping the memory of these and other catastrophic events from fading away.

So, as SPE and its global members look to the future, the following are areas for SPE to continue progressing and promoting its initiatives:

- Promote a visible, industrywide, industry-led commitment to a culture and engaged leadership that supports improvement.

- Superior HSE performance and incident prevention must be addressed within an overall integrated HSE management system. Only through a disciplined, structured, systemic approach can one address the inevitable changes in people, organizations, business, technologies, etc. in an effective and sustainable manner.

- Relatively little progress has occurred in developing and implementing remote real-time monitoring, automation, and use of operational data specifically to reduce systemic risk through better safety information, management, and decision making.

- On a related note for process safety, SPE should continue its collaborative efforts with other organizations within and external to the oil and gas industry, with particular emphasis on the critical actions related to systemic risk management noted in the May 2023 Gulf Research Program’s report.

- Promote industry dialogue on the importance of industry data sharing and analysis, with the objective of identifying trends of concerns and developing effective leading indicators.

- RP 75 and SEMS regulations based on the recommended practice lack guidance on (a) contingent barrier management that depends on human judgment and intervention and (b) application of human factors standards to safety-critical procedures.

- SEMS, and industry in general, lack specific requirements and standards for education, training, and demonstrations of competence for those in safety-critical positions.

- Best practices in the development and use of procedures, checklists, and job safety analyses to enhance performance, situational awareness, and engagement during operations, as used in aviation and other safety-critical industries, have received less attention.

- Develop functional expertise related to the energy transition on topics such as hydrogen and carbon capture and storage, as well as wind and solar concepts.

My challenge to everyone is to take advantage of the various programs and publications that SPE and its partners have to offer to help your organizations meet the growing challenges of HSE in our industry. A key to achieving this is our global members who are willing to volunteer their expertise in planning events and sharing their experiences. Taking a look back at some of the HSE accomplishments of SPE and the industry over the past several years hopefully provides a good example of how the collective power and expertise of our members and partners can help define the way forward.

For Further Reading

API Recommended Practice 75, American Petroleum Institute.

Industry Safety Data Program for the Oil and Gas Industry Phase I Report by P. Hu and R. Schmitt, Bureau of Transportation Statistics.

SafeOCS Industry Safety Data: The Value Proposition for the Oil & Gas Industry by D. Collia and R. Moreau, Bureau of Transportation Statistics.

The Growing Importance of HSSE-SR in Our Industry by R. Moreau, JPT.

The Role of Sustainable Development Planning in Our Industry by R. Moreau, JPT.

Strengthening the Safety Culture of the Offshore Oil and Gas Industry, National Academies of Sciences, Engineering, and Medicine.

Beyond Compliance: Strengthening the Safety Culture of the Offshore Oil and Gas Industry, National Academies of Sciences, Engineering, and Medicine.

Advancing Understanding of Offshore Oil and Gas Systemic Risk in the US Gulf of Mexico: Current State and Safety Reforms Since the Macondo Well Deepwater Horizon Blowout, National Academies of Sciences, Engineering, and Medicine.

SPE 182847-TR Assessing the Processes, Tools, and Value of Sharing and Learning from Offshore E&P Safety Related Data, Society of Petroleum Engineers.

SPE 191770-TR Getting to Zero and Beyond: The Path Forward—Improving Safety in the Oil and Gas Industry, Society of Petroleum Engineers.

SPE Summit: Safer Offshore Energy Systems Summary Report, Society of Petroleum Engineers.

Roland Moreau is an SPE Honorary Member and recipient of the OTC Heritage Award. He retired from ExxonMobil in August 2014 after 34 years of service. Moreau served on the SPE Board of Directors as the Vice President of Finance from 2015 to 2018 and as the Health, Safety, Security, Environment, and Social Responsibility Technical Director from 2011 to 2014. He was then elected as the 2018 President of the American Institute of Mining, Metallurgical, and Petroleum Engineers (AIME) and currently represents AIME as Vice President for the Board of Trustees of the United Engineering Foundation. Moreau was appointed to the National Academies’ Gulf Research Program Gulf Offshore Energy Safety Board in 2021 and currently serves as Vice Chair for the Board. He also previously consulted as a special adviser to the US Bureau of Transportation Statistics on development of the SafeOCS Program, an industrywide safety data management framework. Finally, Moreau is a member of SPE’s HSE Executive Advisory Committee. He holds a BS degree in mechanical engineering from Worcester Polytechnic Institute and an MBA degree in finance from Fairleigh Dickinson University.