Semisubmersible floating production systems (SFPSs) with steel catenary risers (SCRs) are attractive field-development solutions, especially in deeper water of Western Australia. However, SCR design is challenging in the offshore Western Australia environment because of severe cyclonic environments and persistent swells. This paper presents a comparison of three different field-development alternatives that use SFPSs with SCRs in deepwater Western Australia. These alternative solutions are a conventional semisubmersible hull design with steel lazy wave riser (SLWR), a deep-draft semisubmersible hull design with conventional SCRs, and a novel semisubmersible hull design with conventional SCRs.

Introduction

Building robustness in an SFPS, especially when personnel stay onboard during cyclonic events, requires the system to be designed to survive events with return periods larger than the typical 1,000 years adopted for survival events in the Gulf of Mexico. Events with 10,000-year return periods or greater need be adopted for Western Australia. Events with 10,000-year return periods have higher significant wave height and longer peak periods, both of which increase the SFPS motion response, especially in the heave direction. This, coupled with a design location in moderately deep water (<5,000 ft), makes SCR strength design very challenging. In addition, the persistent swell in the Western Australia area makes SCR fatigue design more challenging.

There are potentially three alternatives to overcome the SCR strength and fatigue challenges. One option is to improve the SFPS motion by using a very-deep-draft semisubmersible (VDDS) while maintaining a conventional SCR design. Another option is to use conventional semisubmersible design and adopt an SLWR. The third alternative is to use conventional SCRs with a novel semisubmersible hull design that does not require a deep draft but offers benign motion response, especially in the heave direction.

In this paper, the three different hull/riser combinations are investigated and compared for a presumed wet-tree gas field with a host facility in 4,000 ft of water.

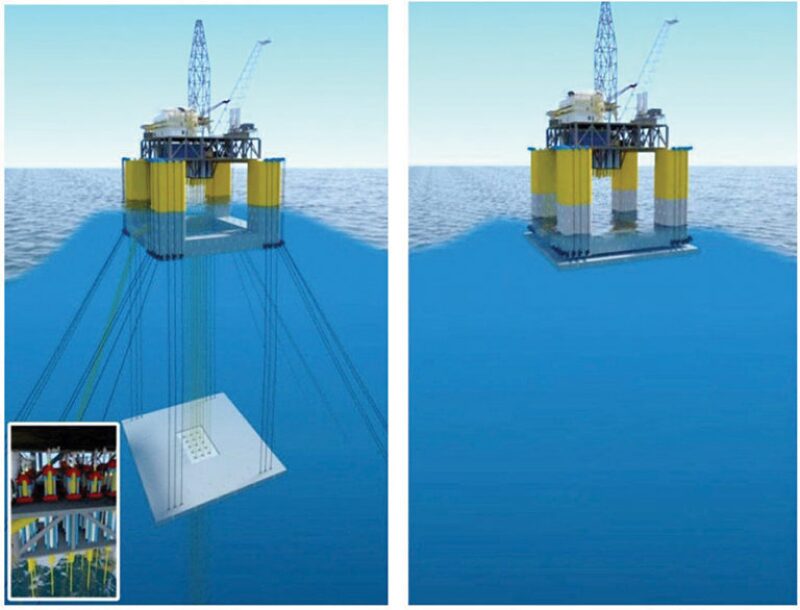

The free-hanging-solid-ballast (FHSB) semisubmersible design fundamentally consists of a conventional semisubmersible hull with four columns connected by a ring pontoon at the keel level. The semisubmersible’s motions and overall performance are enhanced by use of a robust, low-tech feature: namely the FHSB tanks (Fig. 1 above). The FHSB tank is attached to the hull below keel level by means of chains, which pass through guide fairleads at the keel level and connect to deployment winches at the top of the columns. The addition of an FHSB tank to the semisubmersible results in a significant increase in the semisubmersible heave natural period, mainly through its own weight and added mass from its large surface area, while controlling the heave response in the wave-frequency range below 16 seconds.

FHSB has significant cost and schedule advantages during installation phases compared with spars. Unlike for spars, there is no need for topside lift offshore or hull upending for the FHSB semisubmersible design because the topside can be integrated to the hull at quayside. The FHSB semisubmersible hull operates within the normal draft for conventional semisubmersibles, and the solid ballast tank is retracted during preservice conditions (Fig. 1).

The Field

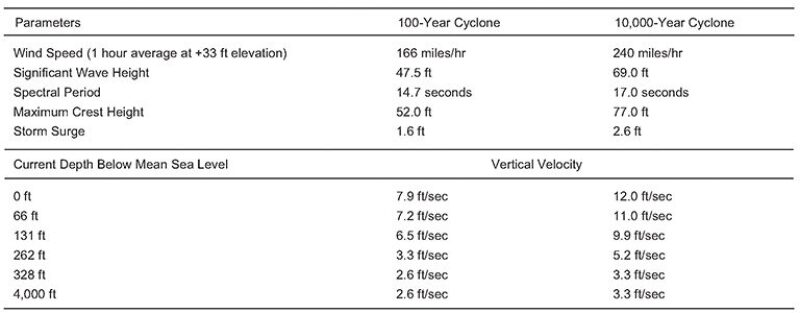

This paper considers a gas field offshore Western Australia at a water depth of 4,000 ft at the semisubmersible location. The key environmental criteria for this region are presented in Table 1.

The assumed total payload for this facility, including the topside equipment, hull storage, production SCRs, gas-export SCRs, and umbilical lines, is 36,000 kip.

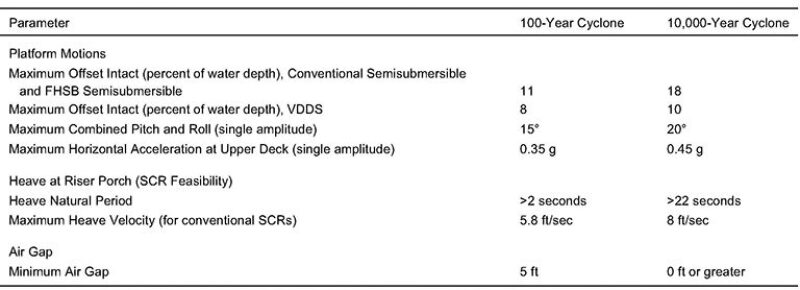

The key design load cases considered in this study are a 100-year extreme and a 10,000-year extreme. Table 2 presents the key limiting global response criteria considered in this study.

The VDDS for Use With Conventional SCRs

A VDDS has been designed to support the 36,000-kip total net payload and satisfy the response criteria listed in Table 2 in the environmental conditions shown in Table 1. The design meets the heave-natural-period requirements in Table 2. Conventional SCR feasibility at this location required an SFPS design with very deep draft of 164 ft, greater than anything accomplished in industry to date. The hull efficiency, defined as the ratio of payload to total hull steel, is found to be 0.7 (i.e., every 0.7 unit mass of topside payload requires 1.0 unit mass of hull steel to support it). This is a low efficiency compared with the efficiency of conventional semisubmersible designs for harsh environments, but it is mainly driven by the motion requirements to enable the use of conventional SCRs.

The maximum vertical velocity at the riser porch is found to be 7.9 and 3.3 ft/sec in 10,000- and 100-year cyclonic events, respectively, which meets the porch velocity requirements in Table 2. The mooring-system design satisfies the 10%-maximum-offset limit. The corresponding deck accelerations in these cases are found to be 0.11 and 0.16 g, respectively, which are also within the global performance limit in Table 2.

The Conventional Semisubmersible Design for Use With SLWRs

A conventional semisubmersible also has been designed to support the 36,000‑kip total net payload and satisfy the response criteria listed in Table 2 in the environmental conditions shown in Table 1. The design meets the heave-natural-period requirements in Table 2. The hull efficiency is found to be 0.9. This efficiency is comparable to other conventional semisubmersible efficiencies for harsh environments.

The maximum vertical velocity at the riser porch is found to be 9.2 and 6.5 ft/sec in 10,000- and 100-year cyclonic events, respectively, which is a suitable response for the SLWR. The mooring-system design satisfies the 17%-maximum-offset limit. The corresponding deck accelerations in these cases are found to be 0.20 and 0.14 g, respectively, which are also within the global performance limit in Table 2.

The Novel Semisubmersible Design for Use With Conventional SCRs

The FHSB semisubmersible has been designed to support the 36,000-kip net payload and satisfy the response criteria listed in Table 2 in the environmental conditions listed in Table 1.

The FHSB semisubmersible design has a significantly long heave natural period of 26 seconds and a high in-place geometric metacentric height of 19.9 ft. Therefore, the FHSB semisubmersible heave natural period is well outside the wave-period range and is very stable in the in-service condition.

The overall hull (including the suspended ballast tank) steel efficiency is found to be 0.89. This is considered high efficiency for this harsh environment. It is comparable to conventional semisubmersible hull steel efficiency. The performance of the FHSB semisubmersible has been investigated further in the time domain under the effect of wind, wave, and current (presented in Table 1). The semisubmersible hull, ballast tank, connecting chains, SCRs, and mooring system have been simulated with software, revealing that the FHSB semisubmersible heave response is significantly smaller than the heave response of the conventional and the deep-draft semisubmersible. The heave response is the dominant mode of motion affecting SCR strength and compression at the touchdown location. Therefore, it is expected that the FHSB would offer SCR motion response comparable with that of alternatives.

For FHSB semisubmersible performance in the critical design load cases presented in Table 2, the maximum offset for intact design under 100-year condition is found to be 10.6% of water depth, which is marginally below the required limit of 11%. The maximum offset for intact design under 10,000-year condition is found to be 15.5%, which is well below the required limit of 17%.

The maximum combined roll and pitch angles are found to be 13.2 and 18.0° in the 100- and 10,000-year events, respectively, which are within the allowable limits.

The FHSB semisubmersible hull and ballast tank are fully coupled in the heave and rotational directions. They also move in phase with similar amplitude in terms of the horizontal-motion low-frequency response.

Riser Systems for the Three Options

This study considers the following three primary hull/mooring/riser combination options for field development:

- SCR with deep-draft semisubmersible

- SLWR with conventional semisubmersible

- SCR with novel semisubmersible

The SCR is also described as “conventional SCR” because it is now a widely used and desired riser configuration. In this challenging field-development case, the SCR requires a very-deep-draft semisubmersible for both strength and fatigue feasibility, with the required draft of 164 ft going beyond industry experience to date. An alternative for the use of SCRs is to use a novel semisubmersible with approximately the same draft as the conventional semisubmersible. A conventional SFPS with a typical 32-m draft can be used together with SLWRs. The SLWR is a newer type of riser system, with which the industry has limited experience. SLWRs have been installed in two projects to date, and buoyancy has been installed in the upper catenary of the SCR in another project.

If the operator of the field desires to use conventional SCRs, the novel semisubmersible is much more suitable than the very-deep-draft semisubmersible from the SCR strength-utilization perspective. In addition, it is possible to use catenary mooring with large offsets with the novel semisubmersible while maintaining SCR feasibility for strength.

Comparison of the Three Hull/Riser Options

The VDDS requires the deepest draft among the three options to control the heave response. This imposes challenges and limits the number of fabrication yards that can be used for the construction of the hull. The reduced heave response was not sufficient on its own to enable a feasible conventional SCR system. The VDDS also requires the largest amount of deck steel among the three concepts because of the required column spacing.

Among the three alternatives, the FHSB semisubmersible is found to require the shallowest draft and the lowest total hull and deck steel and provides superior motion response in the heave direction. The superior heave response allows for a larger offset limit for the FHSB while maintaining the feasibility of the conventional SCR system. The larger offset enables the use of fewer mooring lines, which obviously has economic advantages.

A conventional semisubmersible with the SLWR requires marginally higher total hull and deck steel and deeper draft compared with the FHSB semisubmersible. It also requires the use of 20 chain/wire/chain mooring lines compared with the 16 lines used in the FHSB semisubmersible design.

System robustness for the different alternatives also has been compared. The robustness differentiators between the three options are in the hull, mooring, and riser systems. The conventional semisubmersible option and the FHSB semisubmersible have more-robust mooring systems because of the imposed loads and the soil type in this area. The VDDS and the FHSB semisubmersible have the conventional SCR system, which is considered to be more desirable compared with the SLWR system because of its simplicity and much more extensive use in projects to date. The SLWR is also more susceptible to slugging fatigue (by a factor of two); therefore, it can be a disadvantage if severe slugging is expected. Between the VDDS and the FHSB semisubmersible, the SCR system is more robust when used with the latter.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper OTC 25265, “Field Development Using Semisubmersible Floating Production System With Steel Catenary Risers in Western Australia Harsh Environment,” by Alaa M. Mansour, Shankar Bhat, Dharma Pasala, and Dhiraj Kumar, Intecsea, prepared for the 2014 Offshore Technology Conference, Houston, 5–8 May. The paper has not been peer reviewed. Copyright 2014 Offshore Technology Conference. Reproduced by permission.