Coiled tubing

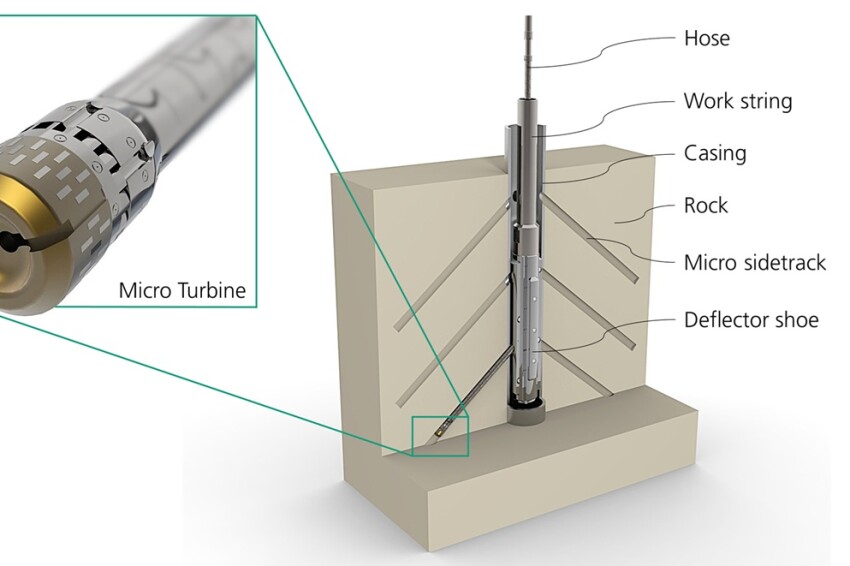

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

This study explores enhancing gas production through a novel combination of prestimulation using a coiled tubing unit and high-rate matrix acidizing.

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

-

A well in the South China Sea was diagnosed by ultrasonic and temperature logging to have a well-integrity problem, forcing the operator to shut in the well because the leak created a high tubing/casing-annulus pressure.

-

In the southern North Sea, many fields suffer from declining gas production because of reservoir-pressure depletion and associated liquid loading.

-

There has been remarkable growth in the coiled-tubing industry in North America, resulting largely from the shale revolution. This growth attracted numerous new players into the industry, in addition to the capacity additions made by the existing service providers.

-

Horizontal wellbores typically encounter inefficiencies caused by friction during drilling and completion operations.

-

Sticking the coiled tubing (CT) is a major operational risk when performing a well intervention with CT. Stuck-pipe incidents often result in considerable production delay or, in the worst case, loss of the well.

Page 7 of 7