Coiled tubing

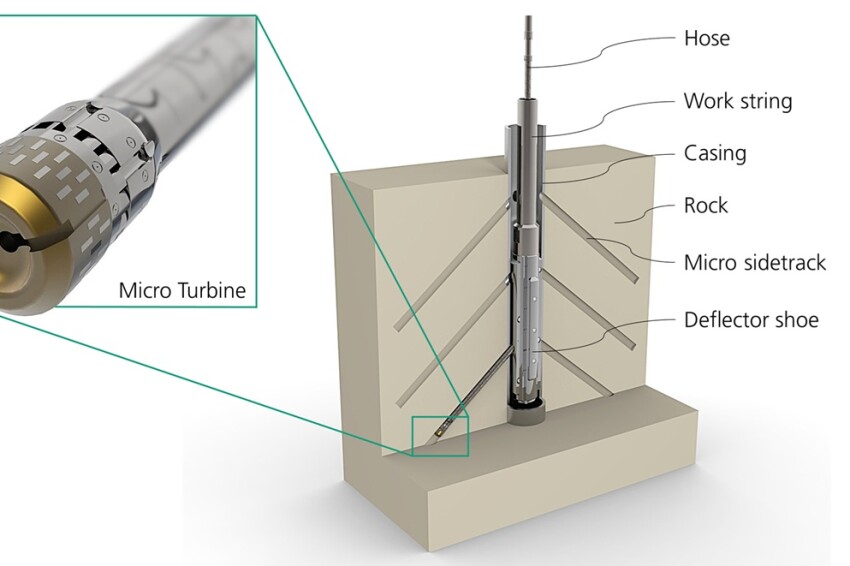

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

This study explores enhancing gas production through a novel combination of prestimulation using a coiled tubing unit and high-rate matrix acidizing.

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

-

This paper presents the challenges and obstacles faced in the use of a new technology for the plugging and deoiling of sections of unpiggable flowlines before decommissioning.

-

The oil industry has responded rapidly to the decline in oil prices of these last few months.

-

Today, there is a need for higher-strength coiled-tubing (CT) grades with better resistance to severe environments and better fatigue performance in both the tube body and the bias weld.

-

Microbial-influenced corrosion (MIC) has been implicated in few corrosion-related challenges in the well-service industry in the past.

-

A common problem in oil and gas wells is excess free gas or water production from only certain portions of the completed interval.

-

The gas-producing carbonate zones of the Ghawar field in eastern Saudi Arabia have been affected by extensive iron sulfide (FeS) scale deposition, reducing overall gas production and increasing risks during well interventions.

-

Weather conditions aging offshore facilities presented challenges during a monsoon in the South China Sea.

-

This work will present an object-oriented tracking system that allows CT operators to monitor defects as they evolve over time.

-

Are we really in an industry that is so mature that it is devoid of new thoughts and incapable of generating new concepts to meet the challenges that we face?

-

While increasing coiled-tubing (CT) diameter remains a theoretical option to improve reach, doing so creates logistical challenges.