Coiled tubing

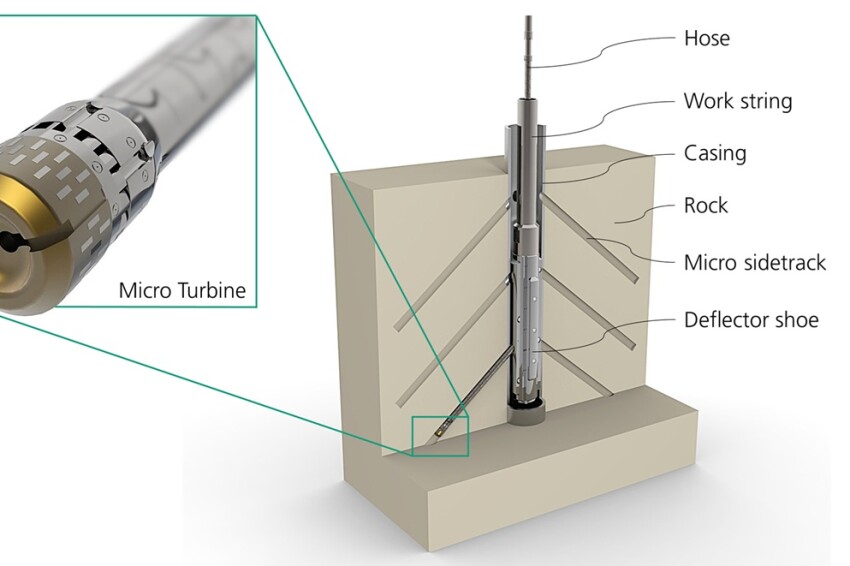

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

This study explores enhancing gas production through a novel combination of prestimulation using a coiled tubing unit and high-rate matrix acidizing.

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

-

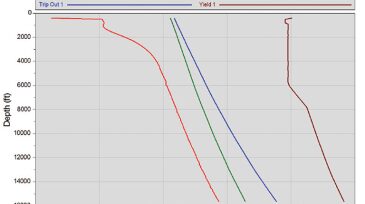

The complete paper describes a recent directional coiled-tubing drilling (DCTD) job completed for an independent operator in the Appalachian Basin.

-

An early commitment to integrate MPD into an HP/HT drilling operation can make MPD more than just an enabling tool and turn it into a performance tool that offers significant operational benefits.

-

The treatment in a deepwater, frac-packed well with fiber-optic-equipped coiled tubing (CT) and a rotating, hydraulic high-pressure jetting tool achieved successful stimulation of a 500-ft-long frac-packed zone after several previous failures using different techniques.

-

This paper discusses a novel approach to abrasive perforating, including the first-ever use of an acid-soluble abrasive material and ending with CT-jetting-assisted nitrified stimulation.

-

Advanced horizontal drilling, multistage hydraulic fracturing, and other technologies have helped make the Vaca Muerta shale oil and gas resource economically viable.

-

A study done to find the root cause of coiled tubing string failures in Montney indicated microbial-induced corrosion, leading the CT service provider to create a biocide treatment program.

-

The coiled-tubing industry is adapting to the changing environment. The next 12 months could bring greater or lesser volatility but the coiled-tubing industry’s record last year indicates that it will still be moving forward.

-

This paper details the planning, design, and execution of a project involving the core drilling of three wellbores using coiled-tubing directional drilling along the future Rogfast tunnel route on the Norwegian coast.

-

The installation of flowlines in ever-deeper and -more-remote areas requires specific technologies for precommissioning. Coiled tubing can be a solution, but long durations may affect tubing stress and fatigue.

-

Larger-diameter coiled tubing recently has been used to perform millouts because of its improved set-down force and increased annular velocities for cleanout purposes. Service companies and operators have reduced the number of wiper trips when using larger-diameter CT, to save time and money.