Coiled tubing

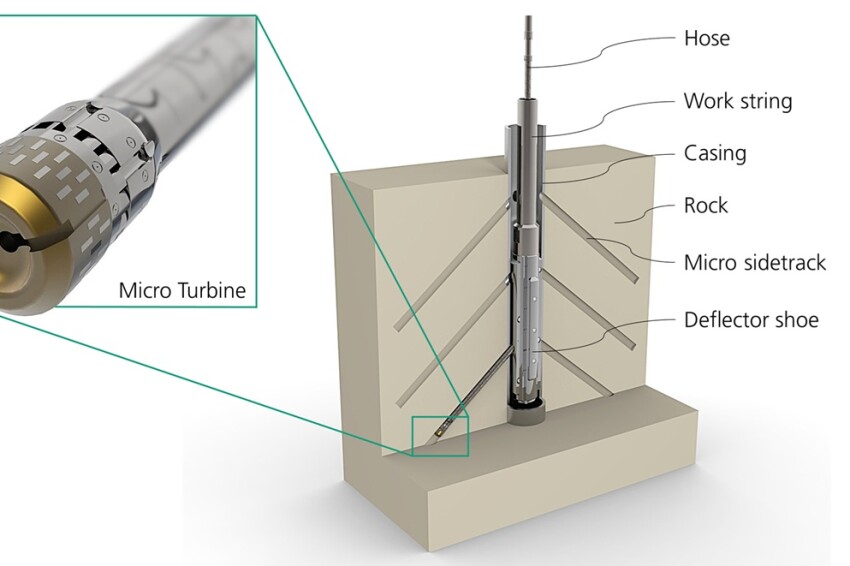

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

This study explores enhancing gas production through a novel combination of prestimulation using a coiled tubing unit and high-rate matrix acidizing.

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

-

The success of water-conformance operations often depends on clear identification of the water-production mechanism. Such assessment can be complicated significantly when formation damage is also occurring.

-

A study by a real-time monitoring company showed that many coiled-tubing strings are retired with a lot of life left in them. It suggested companies could lower costs by using pipe for a longer time and could benefit from multicompany studies showing how their decisions compare to the competition.

-

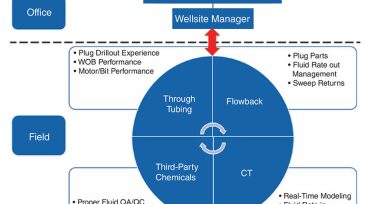

This paper presents a factory-model approach to improving CT drillout performance that has been used successfully for more than 3 years and has become standard practice.

-

The coiled-tubing (CT) industry, like other well-intervention segments, has applied lean philosophies to some aspects of its management, operations, processes, and equipment. When it comes to CT application to specific in-well operations, no two wells are the same.

-

In this paper, the authors study the stress status of CT string held by gripper blocks, the axial force distribution of gripper blocks, and the longitudinal resonance of CT strings in vertical wells.

-

This paper discusses the advantages of the in-line quench-and-temper (Q&T) process, which enhances overall CT life and reliability by producing tubing with more-uniform microstructure throughout its entire length, increased material strength, and improved bend-fatigue performance.

-

The $10 million/year contract covers the inspection and mobilization of casing and tubing at two Norwegian sites and includes extenstion options in 2020 and 2022.

-

If the papers presented at the SPE/ICoTA Coiled Tubing and Well Intervention Conference and Exhibition this March are anything to judge by, then coiled-tubing drilling seems to be regaining some interest in the broader market.

-

When a new horizontal well in Asia was incapable of unassisted flow, coiled tubing (CT) was selected for the perforation and stimulation intervention. Mechanical isolation was required to ensure that the stimulation fluids entered only the new zones.

-

Plug-and-abandonment (P&A) operations can be expensive, leading to negative net present value. Historically, P&A operations in the North Sea—estimated to hold some 3,000 wells of declining production—were performed with either drilling or workover rigs.