Completions

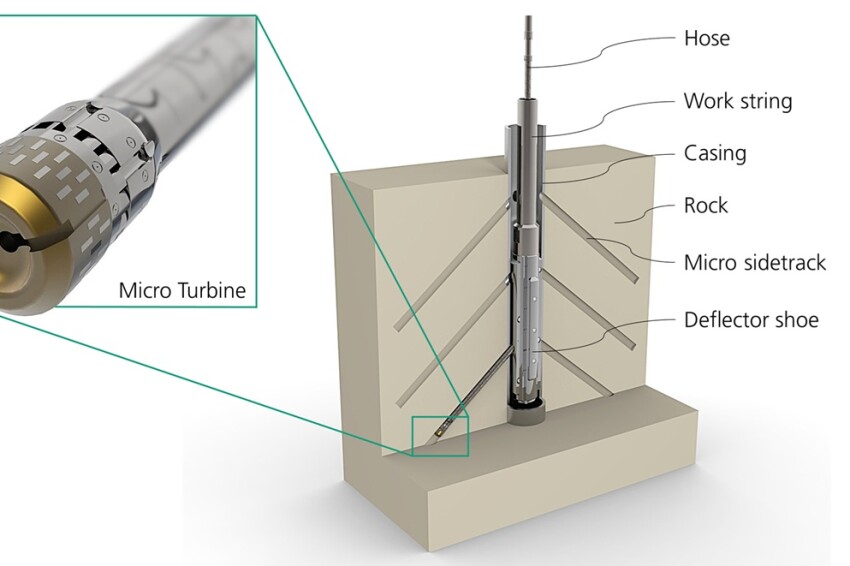

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

Aurora Innovation and Detmar Logistics have inked a deal for 30 autonomous trucks that will begin hauling sand in the region next year.

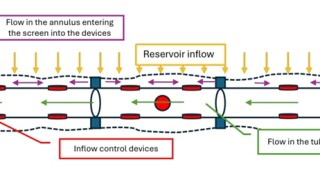

This paper compares various drainage strategies and well completion configurations on the installation of inflow control technology by considering energy efficiency.

-

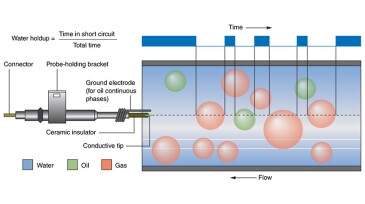

This study describes a technique combining borehole acoustic reflection imaging with production logging in a horizontal well experiencing high water cut with the aim of enabling a mitigation plan.

-

The aim of this study is to address and discuss the reservoir engineering aspects of geological hydrogen storage.

-

The authors investigate the utility of applying unconventional technology to low- or variably producing carbonate reservoirs to increase estimated ultimate recovery and decrease development-scale variability.

-

Operators tell an audience at the Unconventional Resources Technology Conference how a hybrid expandable liner system and machine-learning-based analysis improve the bottom line.

-

The chief operating officer of Chesapeake Energy tells the Unconventional Resources Technology Conference that small wins can pave the path to big achievements.

-

The objective of this study is to use expired medications as green corrosion inhibitors that can be used during stimulation treatments. Because the medications are expired and not fit for human consumption, the cost is inherently low.

-

The Offshore Completions Technical Section is for professionals and academia who are active, or have a deep interest, in offshore completions.

-

Hunt Energy Network invested $10 million into Quidnet to help scale up the company’s concept for geopressured energy storage to the tune of 300 MW.

-

SponsoredTAQA is commencing its journey into the year 2024 with the successful launching of many innovative coiled tubing technologies and solutions, technologies that will transform the nature of well intervention operations into a new era. Read this article and dive into the high-tier coiled tubing technology offerings from TAQA.

-

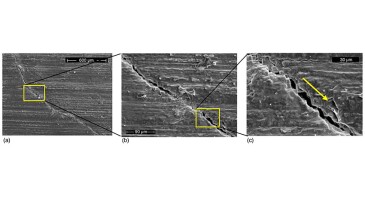

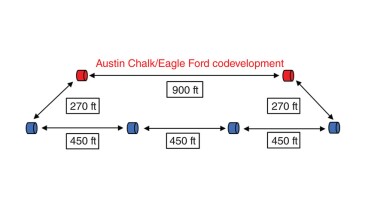

This paper describes a hydraulic fracturing pilot project using a technique that generates higher fracture conductivity to reduce the drawdown during production and improve connection through laminations.