Completions

Ranger acquires American Well Services for $90.5 million, adding 39 workover rigs and boosting its fleet by 25%.

This paper describes development of a high-temperature water-based reservoir drill-in fluid using a novel synthetic polymer and customized with optimal chemical concentrations and sized calcium carbonate.

In this case study, a geomechanics-based approach was used to create bridging and sealing at the fracture aperture using a biparticle self-degradable lost-circulation-fluid system.

-

ExxonMobil submitted a proposal to Colombian authorities to develop a hydraulic fracturing pilot project in the Magdalena Basin. Colombia wants to drastically raise its declining reserves-to-production ratio by tapping into shale.

-

Contractor renews incident-response partnership for 2 additional years.

-

New Testing Facility Built To Prove Whether Natural-Gas Foam Is Shale Sector's Next Fracturing FluidA 6-year R&D project concludes with the completion of a technology kit designed to study how combining highly pressurized natural gas and water could be a holistic alternative to traditional hydraulic fracturing.

-

The qualification and first deployment of a low-solids, oil-based completion fluid that incorporates a newly developed, high-density brine as the internal phase to extend the density limit is discussed.

-

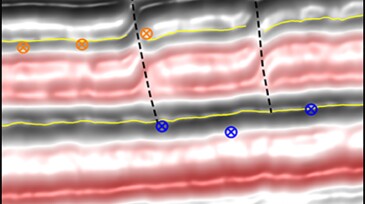

A pressure-monitoring technique using an offset sealed wellbore as a monitoring source has led to advancements in quantifying cluster efficiencies of hydraulic stimulations in real time.

-

S13Cr tubing specimens experienced stress corrosion cracking with phosphate-based completion fluids contaminated with mud and oxygen, whereas formate-based completion fluid is compatible with the tubing.

-

A well-flux surveillance method to monitor and ramp up production for openhole standalone screen completions is described that optimizes production by considering risks of production impairment and screen-erosion failure.

-

The deal fills a gap in the software developer's production line that is focused on drilling, production, and land management applications.

-

Is it possible to fracture a well using power off the grid? The answer is yes, but sharp electric engineers are required.

-

The two-well stimulation approach is delivering big savings to first adopters. A new report from Rystad highlights how the development is taking shape.