Digital oilfield

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

This paper offers an exploration into the field applications of multiphase flowmeters (MPFMs) across global contexts and the lessons learned from implementation in a smart oil field that uses several types of MPFM.

-

This paper describes how the use of production-modeling tools, coupled with field pressure/temperature-data-acquisition systems and programming software, served as a means to improve production allocation and surveillance on a real-time basis in the Greater Angostura Field.

-

The application of high-precision downhole temperature sensors has resulted in pressure-transient analysis (PTA) being complemented or replaced by temperature-transient analysis (TTA).

-

Investment in digital technologies may increase project efficiency and reduce costs. However, Technip’s chief executive officer (CEO) said it is equally important to strengthen relationships with companies along the supply chain.

-

Visualization technology has played a key role in reducing operational expenditure (OPEX) and improving collaboration, thus maximizing uptime across the industry throughout the asset life cycle.

-

A recently released report predicted that IoT networks will not take up as much of the overall market share as previously anticipated.

-

Distributed temperature sensing (DTS) is the most common fiber-optic measurement used for steam-assisted-gravity-drainage reservoir monitoring.

-

Although early inflow control devices and intelligent completions (ICs) were introduced almost 20 years ago, completion technology has not kept pace with advancements in drilling technology.

-

As the drilling industry improves its efforts to capture drilling operation activities in real time, it has generated a significant amount of data that drilling engineers cannot process on their own.

-

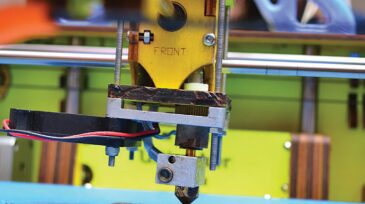

Researchers at Heriot-Watt University in Edinburgh, Scotland, are building replica core samples using 3D printers and installing sensors inside them as they go. Their goal is to directly monitor pore-scale flow behavior from the inside of these so-called “smart rocks.”

-

A real-time method is presented to predict impending stuck pipe with sufficient warning to prevent it. The new method uses automated analysis of real-time modeling coupled with real-time-data analysis.