Digital oilfield

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

This paper offers an exploration into the field applications of multiphase flowmeters (MPFMs) across global contexts and the lessons learned from implementation in a smart oil field that uses several types of MPFM.

-

Many business and digital corporations claim that between 100 billion and 200 billion devices could be connected by 2020.

-

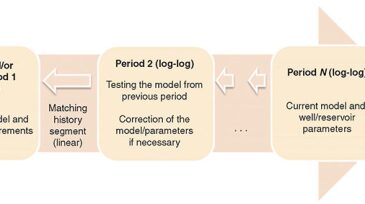

Permanent downhole gauges (PDGs) provide vast amounts of pressure-transient and rate data which may be interpreted with improved pressure-transient-analysis (PTA) approaches to gain more knowledge about reservoir dynamics.

-

This paper proposes a framework based on proxies and rejection sampling (filtering) to perform multiple history-matching runs with a manageable number of reservoir simulations.

-

This paper describes the development of “digital-rocks” technology, in which high-resolution 3D image data are used in conjunction with advanced modeling and simulation methods to measure petrophysical rock properties.

-

There is talk about digital oil fields and big data and some striking examples of their power. But in real oil fields, a lot of operators are still running fields with systems relying on big paper.

-

A new intelligent model that successfully learns from high-dimensional data and effectively identifies high-production areas and optimum lateral-re-entry candidates is presented.

-

For thin-oil-rim reservoirs, well placement, type and path, and well-completion methods, should be evaluated with close integration of key reservoir- and production-engineering considerations.

-

Artificial-intelligence (AI) -based methods have become mainstream engineering, and we as practitioners need to have a firm understanding of the principles and be ready to apply them when the opportunities arise.

-

Al Khalij field offshore Qatar is formed of a highly heterogeneous carbonate reservoir with significant remaining dynamic uncertainties.

-

Case studies from around the world prove that big rewards await companies that optimize the artificial lift systems keeping their mature fields alive. The success stories involve a mix of monitoring, automation, and performance tracking.