Enhanced recovery

Secondary and tertiary efforts are critical for sustaining the productive lives of unconventional plays.

The three papers selected for this feature highlight some creative solutions that aim to increase project value by either increasing recovery or optimizing injectant cost, or both.

This paper discusses the effect of injected-polymer viscosity on various aspects of a project, from recovery to surface facilities, including both theoretical arguments and practical field experience—which do not always align.

-

SponsoredBy adopting enhanced oil recovery (EOR) techniques, the amount of oil that could be recovered could be increased by as much as 30% to 70%. Low Salinity Water Flooding (LSWF) is flexible and has a low cost, with a readily accessible feedstock – seawater.

-

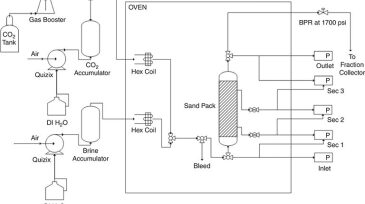

Aqueous foam has been demonstrated to have promise in conformance-control applications. This paper explores the foaming behavior of a CO2-soluble, cationic, amine-based surfactant.

-

A carbon-dioxide (CO2) -foam enhanced-oil-recovery (EOR) pilot research program has been initiated to advance the technology of CO2 foam for mobility control in a heterogeneous carbonate reservoir.

-

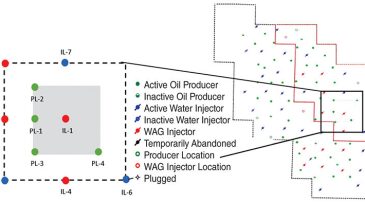

This paper presents an analysis of a CO2-foam-injection pilot in the Salt Creek Field, Natrona County, Wyoming.

-

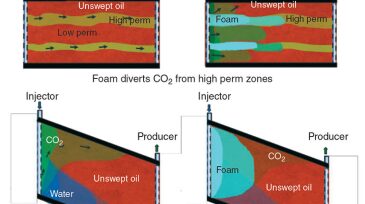

In my previous features, I discussed the challenges facing carbon dioxide (CO2), both technical and economic. By far the biggest use of CO2 is in enhanced oil recovery (EOR). In this feature, the focus is on overcoming the biggest challenges facing CO2 EOR—gravity override and mobility.

-

A horizontal-steam-injection pilot project has been under way for the last 4 years in the Kern River heavy-oil field in the southern San Joaquin Valley of California.

-

The evolution of horizontal drilling and multistage completions has changed matrix stimulation from the “more acid, better result” belief to effective lateral distribution and deeper penetration with less acid.

-

CO2 injection is a successful EOR technology that has been deployed extensively in the Permian Basin. Further expansion of CO2 EOR has been limited by the availability of affordable CO2 rather than the existence of suitable target reservoirs. This situation may be about to change.

-

While the floating liquefied-natural-gas (FLNG) option initially looked promising, high capital expenditure and very high operational expense (OPEX) have limited its potential application, with four potential FLNG projects being canceled in Australasia in the last 2 years.

-

Production from an offshore Angola field has been decreasing because of subsea pressure declines amid water-cut increases and limited gas compressor capacity. The development process leading to the selection of high-boosting multiphase pumps is described.