Inspection/maintenance

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

This paper describes the development of a system for comprehensive mapping and asset registration using a digital-twin approach.

-

The testing, inspection, and certification company is reporting a 900% rise in demand for the remote inspection of offshore assets and equipment since the outbreak of the COVID-19 pandemic.

-

The AI-driven tool will detect anomalies in subsea oil and gas infrastructure.

-

This paper presents a fatigue-prediction methodology designed to extend the life of unbonded flexible risers and improve the accuracy of floating production, storage, and offloading vessel response analysis.

-

Gecko Robotics is providing the energy industry with artificial-intelligence-enabled robots to inspect infrastructure and supply massive amounts of data to help predict failures before they occur.

-

Material selection is a first line of defense against corrosion. This article reviews how to recognize pitting and crevice corrosion, as well as how to optimize tubing material selections for marine oil and gas applications based on the material’s PREN value.

-

The methodology is the industry’s first to address CUI. Along with DNV GL’s new technology, maintenance costs may be reduced by up to 50%.

-

The largest oil and gas major in the US is calling for tighter rules around methane monitoring, wellhead venting, and the replacement of equipment components with “high-leak potential.”

-

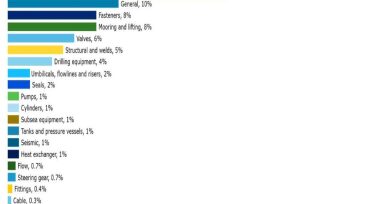

DNV GL researched over 1,000 failure cases to identify failure-prone components. The research is based on cases from its global network of labs.

-

Aker BP showcased the Spot robot recently. Spot will be part of the company's initiative that will explore how robotics systems can be used to make offshore operations safer.

-

The data-driven maintenance program incorporates riser condition, usage, and fatigue analysis with a risk-based inspection process.