Pipelines/flowlines/risers

The awards build on Tenaris’ role in earlier phases of the ultradeepwater Black Sea project.

Engineering, procurement, construction, and installation awards made at the end of 2025 are expanding Saipem’s role in Turkey’s two largest offshore gas fields, plus Saudi Arabia’s Berri, Abu Safah, and Marjan oil fields and Qatar’s North Field gas giant in the Persian Gulf.

The Gorgon Phase 3 project aims to counter declining reservoir pressure to sustain gas supplies to Western Australia’s domestic market and support LNG exports to Asia.

-

The funding from Chevron Technology Ventures and Energy Innovation Capital will help scale Ingu’s data collection platform and analysis for its Pipers technology, a pipeline screening tool launched last year.

-

The pipeline is the first step in developing the infrastructure needed to transport gas between Pluto LNG and the Karratha Gas Plant in Western Australia. Woodside is targeting 2022 startup.

-

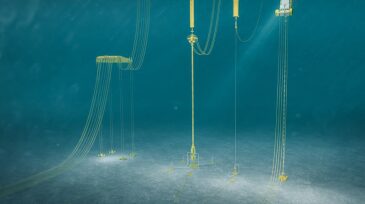

Nonmetallic, thermoplastic composite pipe (TCP) technology can now be found in every oil and gas region globally and can operate at pressures of up to 12,500 psi, and in water depths as low as 3000 m. The focus is now on developing and deploying TCP risers for extreme environments.

-

This paper describes a material designed to interact specifically with highly corroded and weathered pipe to enable in-place application and refurbishment.

-

Internal corrosion has caused ADNOC to suffer loss of containment in oil flowlines in a giant onshore field. This paper describes the successful 5-year field trial program and confirmation that HDPE liner application in carbon steel pipe can be a cost-efficient way to mitigate internal corrosion.

-

The completion of the subsea installation marks another major step for one of several projects scheduled to tie back to the Gjøa platform in the Norwegian North Sea. Production for the Wintershall Dea-operated project is expected to start up in 2021.

-

The subsea operations company said its most recent campaign is the first fully unmanned offshore pipeline inspection completed “over the horizon,” surveying up to 100 km from the shore.

-

After protesters disrupted construction of an oil pipeline in North Dakota by chaining themselves to construction equipment and pitching tents along the route, oil and chemical companies found a way to keep it from happening again. They made it a crime.

-

This paper details the methodology adopted to monitor gas-pipeline leakages using distributed fiber-optic sensing, using an optical fiber as a linear sensor to provide valuable measurement information from all along the fiber itself.

-

Trafigura confirmed that it had begun shipments from the Permian to Corpus Christi via the pipeline, which has a 670,000-B/D capacity. Operator Plains All American announced last week that it had completed work on the pipeline.