Safety

This study ascertains the capital expenditure and operating expenditure associated with the reuse of existing facilities, specifically regarding a carbon capture and storage project being prepared in South Korea.

Sponsored

Advance your career with the new Pipeline Engineering Program at the Technical University of Leoben, a 5-month course combining on-campus and online learning, integrating industry expertise, engineering practice, and future-ready skills for professionals in oil, gas, and emerging energy systems.

A resilience-based approach to safety was the focus of a panel of experts at the 2025 SPE Annual Technical Conference and Exhibition in Houston.

-

Electrical networks of oil and gas facilities are extensively equipped with oil-filled transformers. The oil in the transformers, however, can be a major hazard to people, assets, and the environment in the case of major oil leaks or explosions. This paper will discuss common failures of oil-filled transformers and any protective measures and solutions that can avoid …

-

The civil engineering curriculum in colleges and universities across the United States needs to include information on workplace safety, argued expert panelists during a recent roundtable discussion. Panelists debated how to achieve that goal and learned about the experience of another industry that successfully tackled the same problem.

-

Continuous operation requires people to work in shifts. Ensuring safety and efficiency requires critical information to be communicated between these shifts. In 2018, the Abu Dhabi National Oil Company (ADNOC) embarked on improving its operational integrity, and shift handover was seen as one of the core elements. ADNOC Onshore worked to standardize shift handover at …

-

The investigation and cleanup of the oil spill, originating from a rupture in an Amplify Energy pipeline in the Beta field, is ongoing.

-

Italian oil major Eni has developed a tool with the aim of determining the level of safety knowledge and competencies of all supervisory personnel, thus identifying all safety areas that might need a specific, customized, and effective training approach that could fill competency gaps and strengthen safety supervision at work sites.

-

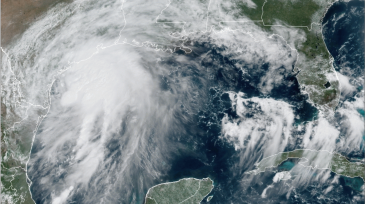

Shell moves nonessential personnel off its Perdido deepwater platform as a result of Tropical Storm Nicholas.

-

Strong storms can trigger steep, breaking waves that slam into platform and wind turbines with tremendous force. Scientists at the Norwegian University of Science and Technology and SINTEF are studying the behavior of offshore structures subjected to these kinds of waves. Their goal is to increase safety at sea.

-

A fire at Ku-Maloob-Zaap killed five and sidelined more than 400,000 BOPD.

-

Search for the missing workers continues as the Mexican state oil company investigates the cause of this latest blaze.

-

A subsidiary-owned pipeline near Marmon, North Dakota, spilled more than 700,000 bbl of produced water over a period of almost 5 months in 2014–2015.