Offshore/subsea systems

The awards build on Tenaris’ role in earlier phases of the ultradeepwater Black Sea project.

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

-

The contractor will supply subsea equipment for the Brazilian state oil company’s Marlim, Voador field revitalization project.

-

Follow-up well could help prove up 100-million bbl find.

-

Subsea production equipment falls to seafloor after winch wire malfunction.

-

The Magnus oil field in the North Sea catalyzed a major leap for subsea control systems. The original development of the multiplexed electrohydraulic control system has developed into a multimillion-dollar subsea controls industry.

-

A new offshore service company has been created combining Baker Hughes’ subsea equipment operation and the drilling hardware made by MHWirth. The joint venture’s goal is to grow and go public.

-

Shell and Tomson Technologies completed field trials in the Gulf of Mexico using new nanoparticle-enabled phosphonate and polymer inhibitors that improve the treatment lifetime of scale squeezes.

-

Jumbo Maritime's heavy-lift crane vessel Fairplayer completed the work.

-

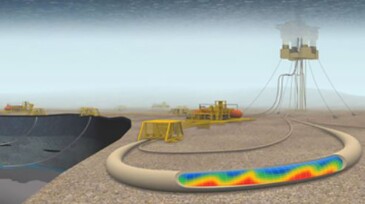

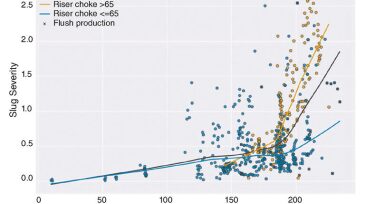

The complete paper discusses the successful application of a data-driven approach to analyze production data and identify root causes of slugging in a subsea production system on the Norwegian Continental Shelf.

-

The subsea-technology company’s LUMA X subsea wireless communication modem will enable real-time streaming of HD-quality video and 4K images wirelessly through water, allowing the operators of autonomous underwater vehicles to monitor its interventions from its control rooms onshore.

-

The Bubbleheads, a team of four deep-sea saturation divers, share the view of a bellman.