Offshore/subsea systems

The awards build on Tenaris’ role in earlier phases of the ultradeepwater Black Sea project.

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

-

Proposal requests were sent to companies to solicit partnerships for the project with ADNOC and ADPower.

-

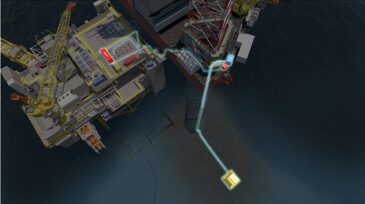

The A-frame is DNV certified. TechnipFMC’s ROVs will deploy in GoM later this year.

-

The complete paper presents a practical approach for validating design-verification analysis for subsea equipment, using a representative pressure valve block to correlate finite-element analysis (FEA) predictions for strain changes with actual measured changes.

-

This paper identifies potentially significant hidden value of subsea multiphase boosting technology, or aspects of it that have not received adequate attention during the field-development decision-making process.

-

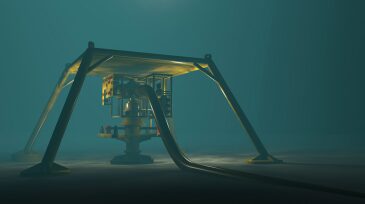

The Dalmatian project is a brownfield development and represents the world’s longest multiphase tieback by boosting at some 35 km; the boosting system is installed at approximately 6,000 ft water depth.

-

The motto of the Olympic Games is “Citius, Altius, Fortius,” Latin for “faster, higher, stronger,” which emphasizes the concept of pushing the limits. As an engineer, that approach really speaks to me—and offshore installations, and especially offshore tiebacks, illustrate that concept very well.

-

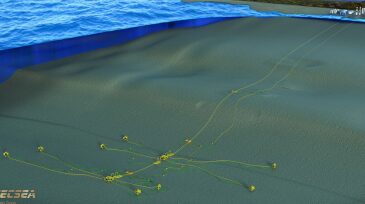

Eni conducted a research project to explore the maturity of new technologies to enable economical development of deepwater prospects with tieback distances longer than 50 km and 150 km, respectively, for oil and gas fields.

-

This case study describes how gas condensates within a subsea tieback system behave very differently to condensed water from a wet-gas system and therefore a pseudo dry-gas system needs to be configured differently for gas-condensate developments.

-

A subsea water-treatment system designed to leverage space availability, steady temperatures, lower bacteria levels, and other natural benefits of the seabed environment was successfully installed during pilot testing at the Ekofisk field offshore Norway.

-

Aimed at streamlining manufacturing processes and significantly reducing costs, the practice provides standardized operator requirements that DNV GL says will ensure consistency in the fabrication of subsea pressure retaining equipment such as wellheads, manifolds, and jumpers.