A Smart Investment That Saves Lives and Future Capital

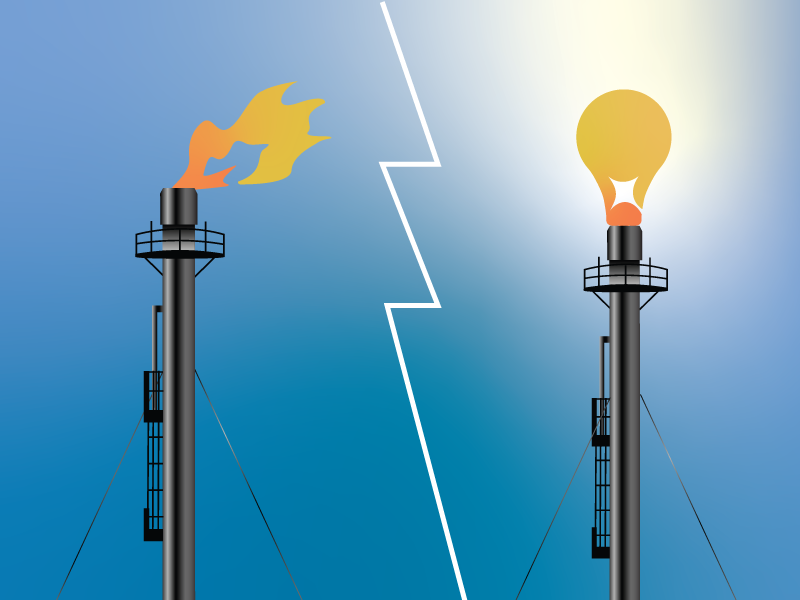

Often thought of in terms of cost and safety, flare systems are a critical part of any operation—and their value is never more apparent than in the event of a failure. With revenue lost due to downtime, the cost of repairs and replacement, environmental penalties, and compromised worker safety at stake, investing in a flare system is crucial to ensuring your equipment remains operational and your people are protected.

However, evaluating the flare systems and safety could be made more efficient. Workflows require engineers to use numerous disparate applications to complete a single study, with multiple manual iterations required between tools. In addition to wasting valuable time, this also runs the risk of introducing errors in the data transfer process and of using out-of-date information due to different application update cycles. This results in fewer completed studies, leading to riskier operations with working conditions and systems that may be more prone to failure.

Achieve Improved Safety Conditions and Increased Uptime With Integrated Flare System Analysis

By combining all these separate tasks into one application, engineers can create comprehensive pressure safety studies with significant time savings. As a result, they can complete more studies to uncover where and when investment needs to be made to keep operations running.

The Symmetry process simulation platform improves modeling accuracy and delivers insights that help drive operational efficiencies and reduce the risk of unplanned downtime. Available to operators through the cloud-enabled DELFI environment, it can be run on any laptop and be purchased on a monthly subscription basis.

Scenario 1: Understand overall emissions through flare system analysis

With a better understanding of the underlying fluid, operators can more accurately estimate emissions and more efficiently complete emissions reporting. After inputting the relevant dimensions and parameters, users get a single report that details all emission streams, storage vessels, and emission sources.

Scenario 2: Save time by quickly evaluating flare systems

There are enormous benefits to be gained by having a single application to incorporate multiple flow sheets when running scenarios and evaluating various strategies. With an integrated application, a change made on any flow sheet is immediately reflected elsewhere, reducing the need for manual data transfer or validating previous models.

Scenario 3: Reduce Capex and Opex with dynamic simulation

Simulations enable operators to prepare for adverse events and take the right corrective action to prevent them from occurring—and avoid the associated downtime, cost of repairs, and more. By running scenarios that show the causes and effects of various failures, engineers can achieve safer equipment design, reduce the risks of pipe rupture, and ensure worker safety for long-term integrity and regulatory assurance.

Learn how to run dynamic process simulations and dynamic flare models within a single model file. Watch how to run three different scenarios to better understand your flare systems’ emissions, operations, and safety profiles. Making a small investment now results in greater efficiency and reduces risk.

View this step-by-step video >>