Plugs used in fracturing do more than just plug.

In addition to isolating stages during fracturing, they often provide the first warning when casing has been deformed—an all-purpose description for pipe that has been bent, squeezed, or gashed.

A vague label for the damage is useful because most often those dealing with the problem will never know more about the damage than the inner diameter of the casing has been narrowed—ovalized is the popular term for it—and that they need to find a smaller-diameter tool to get past the obstacle.

Eric Davis, the global completions chief for ConocoPhillips, offered a rare public presentation about what can be learned by digging deeper into the reasons why a plug, frac gun, or bottomhole assembly (BHA) cannot pass through a casing diameter.

A major message in a panel discussion during the recent virtual 2020 Unconventional Resources Technology Conference (URTeC) was that investigating casing can yield surprising results.

Davis told the online audience he hoped the presentations would “scare you into getting more data.”

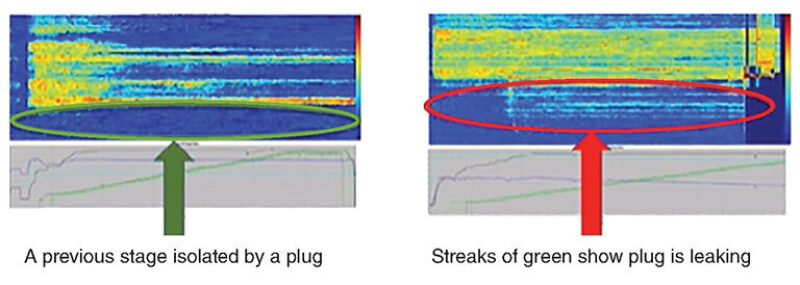

Davis shared an observation made while watching fracturing in progress on a screen displaying temperature and acoustic data collected by fiber-optic cables attached outside the casing for distributed temperature sensing and distributed acoustic sensing.

As the stage progressed, cooler injected water (shown in green) mixed with the warm reservoir fluid (in blue) (Fig. 1). Temperature data from the fiber-optic cable showed the previous stage as all blue, indicating the plug was sealing.

Then the colors of the previous stage started changing as cooler water leaked in and green streaks began bleeding into the blue of the previous stage; then “it all went blank.” The fiber had been severed, Davis said, adding that seeing it in real time “was quite shocking.”

The fiber optic was still working on the yet-to-be-fractured upper stages, but “as we moved up the hole, we kept parting the fiber.”

For the team involved it was a big loss in terms of the cost of the fiber installation and the data they had planned to collect. But for Davis the value of what was learned after the fiber was cut “is far more valuable than the lost fiber-optic installation.”

Collecting the information required sending diagnostic tools downhole to inspect the damage.

Gashes were found in the casing. They appeared to have been cut by the fast-flowing water-sand mix that may have begun as a small leak, grew in volume, and severed the metal tube holding the fiber-optic cables on the outside of the casing.

“You can see it looks like the packing element is where the erosion occurred on a lot of cases,” Davis said.

They also learned that the metal in the casing is softer than the plugs. Davis said, “We were preferentially eroding casing over the plug.”

They found “total casing breaches” created by the high-pressure stream of fluid and sand on 25% of the plug locations examined on multiple wells.

A Muffled Warning

The events most often associated with casing damage are not the sort of things that demand an investigation. Plugs provide a type of warning system by identifying spots where the circular tubing has been narrowed to an oval or where a too-tight turn does not allow a long tool to pass through.

“The only way you will know you have an issue is you cannot get coiled tubing in, cannot get a perf gun in, you cannot get a plug in. Something you were doing you can no longer do,” Davis said.

These events suggest something is wrong but not much else. The ConocoPhillips presentation was a rare example of what can be learned from detailed measurements and imaging.

ConocoPhillips is collecting that data in the Montney formation in Canada, where the frequency and severity of casing issues makes this information more valuable than in US shale plays where it has not been a significant issue.

“You can lose zones, stages, sections, or even entire wellbores … we have lost all of them,” Davis said.

Davis said ConocoPhillips is making a significant investment in understanding the problem to find ways to reduce the risks during fracturing and to “preserve the ability of the company to stimulate and go back into these wells in the future.”

Using measurements made with calipers and ultrasonic imaging, they have observed sharp bends—in one instance, a 1-in. shift in the center of the wellbore in one 18-in. section.

“No wonder we have trouble with getting plugs, perf guns, and long, stiff BHAs into the hole,” Davis said.

Plugs were also found at deeper depths than they were supposed to be, sometimes within the boundaries of a previously fractured stage.

Davis said, “I can tell you and show you with certainty we have wellbore shifts, we have bends, we have ovality, we have shear, we have deformation, we have plug-induced erosion, we have breaches, we have casing and equipment damage, and no doubt we have had” less-effective stimulation due to ineffective isolation. He concluded the seemingly exhaustive list by saying, “We probably know less than we think we know.”

International Focus

ConocoPhillips has many more wells in US shale plays but it has focused its research effort in Canada because that is “where we see it is happening a lot of the time,” Davis said.

“Most US unconventional plays are in favorable, normal-stress regimes. Outside the US there are more challenging conditions,” said Gustavo Cuervo, a panelist who is a geomechanics team leader for Chevron with experience in Argentina.

The difference is in the geology. In places such as the Vaca Muerta in Argentina, the “earth loads” can cause weakly connected features in the rock fabric. As a result, natural fractures or bedding planes shift and apply force that can bend, twist, and sever casing. In comparison, US plays are simpler to understand than tectonically challenged basins.

Nonetheless, a panel discussion on casing deformation held after the SPE Hydraulic Fracturing Technology Conference and Exhibition (HFTC) in February drew hundreds of completion experts, about two-thirds of whom said they work in US shale plays. That percentage and others are based on a survey conducted during the session using a mobile phone app.

When asked if they suspected casing deformation on a few of their wells, nearly two-thirds said yes. They were split into two groups: 34% indicated seeing it in 5–10% of their wells and 31% in up to 5% of their wells.

The leading source of those suspicions (47% of responses) was a “frac plug failed to reach set depth,” followed by 21% responding that coiled tubing failed to complete a mill-out run.

The survey may only represent the views of those who were motivated to spend an afternoon listening to a panel discussion on the topic, but the strong turnout and participation in the HFTC session and at other conferences suggest a significant number of people have experienced casing trouble in US plays.

Operators who have imaged the inside of the wellbores, often for other reasons, have been surprised to find casing damage.

“We’ve seen lots of the damage in wells across both Canada and the US. It’s been really surprising to see the frequency with which they occur and how it typically flies under the radar of most operators unless they get a set of eyes downhole that can scan an entire wellbore” said Stephen Robinson, chief executive officer of DarkVision, a company that uses ultrasound to conduct downhole imaging in murky environments.

“The common problem that we see is severe casing damage and wall loss, including full breaches of casing, around where plugs have been set. In most cases, it appears to be from erosion around where the sealing elements touch the casing,” he said.

The damage has often been discovered incidentally on jobs where the company was hired to image perforations after fracturing was completed to identify and measure the fractures which took in the most fluid and sand.

“When we first started inspecting these types of wells in 2019, we thought the first few were anomalous events, and so did our customers. Now that we’ve inspected over 60,000 perforations in North America, we’re seeing those problems are more prevalent than anyone understood,” he said.

Plans A, B, C, D . . .US operators face an economic barrier to understanding casing deformation. Given the current dismal state of the US shale sector, an occasional stuck plug is not going to be a corporate spending priority. Still, stuck plugs happen and shut down work until the team in the field can find a way to get past that obstacle. The usual solution sounds simple: run a plug small enough to fit through that tight spot. But there are questions beginning with, how small does it need to be? There are smaller-diameter tools built to seal relatively large spaces, but questions about the cost and the reliability of plugs with greater expansion ratios need to be answered. And even if there’s a plug that works and can be delivered promptly, will the perf guns and coiled-tubing milling tools be able to fit through? If there are questions about whether it will be possible to run the coiled tubing needed to mill out the plug, the best solution may a dissolvable plug. Those are built to fade away after completion, if the temperature and chemical conditions in the well meet the tool’s design specifications. Paying a completions crew to wait for that problem to be solved can get expensive. The best business decision has sometimes been to send them off to another job, with no guarantee they will ever get back to complete this well. Based on that experience, panelists who have worked in the extreme plays say it is critical to speed the process with a detailed plan for dealing with obstructions. “On the last two pads, more than 95% of scope on the plan was achieved. That was a significantly better outcome because we had plans B, C, and D ready to go,” Davis said. |

Looking at Leaks

SPE papers reporting that plugs leaked during fracturing go back at least to 2013, around the time the industry began to use fiber optics to observe temperature and acoustic changes along the wellbore during fracturing. The water-temperature tracking data could not identify the cause of the leaks, but they indicated the plugs may have been the problem.

Reports of casing deformation suggest an alternative explanation: round plugs are being used to seal oval-shaped holes or are being used in bends—leaving room for leaks.

“When we started instrumenting these wells, we saw we do have ovality and bends [in casing],” Davis said.

ConocoPhillips also noticed that the length of casing that was deformed represented a tiny part of the 5,000- to 10,000-ft length of a lateral.

“If you just think of it from a statistical standpoint: If you are in a 2-mile horizontal well, and you have got a half-dozen twists and turns and bends where Mother Nature is nasty to you,” the odds that the fracture design will place multiple plugs on those 6 ft among 10,000 is really low, Davis said.

On the other hand, the chance that plugs will be squeezed through one or more of those pinch points is high.

“We think there is more damage actually occurring when shoving plugs through bends,” Davis said, adding, “Statistically 99.9% of the casing in those holes is in fairly good shape, but there are some twists and turns and bends.

“Logically while pushing, pumping, or running a plug through them we are doing some sort of irreparable damage to the plug,” he said.

Even if the casing at that spot is perfectly circular, a plug may fail to seal because it became damaged when key parts were broken or torn off during its placement downhole. “It is more important to be studying survivability [of the plug] than necessarily setting [it] in an irregular hole,” Davis said.

One tool ConocoPhillips would like to have in the Montney is a higher-performance plug. It would be extremely durable, slim enough to fit through tight spots, and still be able to reliably seal relatively large areas which may be irregularly shaped.

For that wish to come true, operators in high-risk plays will need to find a company willing to take on the difficult technical challenge of developing tools for a small segment of the market.

Another need is an early-warning system for plug problems using the pressure and pumping data gathered during fracturing.

ConocoPhillips has identified some specific pressure signatures in the data that may help them monitor things like plug performance, Davis said. They are looking for early warnings to enable the avoidance of plug-related events. But plug behavior varies.

“I wish I could say you see a precursor. Sometimes there is a quick pressure drop. It hasn’t always been the same,” he said. With fiber optic they have seen evidence of steady erosion in some cases, and they have also seen plugs that begin to leak, then stop, and then you lose it all and “you are clearly” treating multiple perforations.”

Building Doglegs

There are fewer natural threats to casing in US shale plays, but there are plenty of other ways to bend it out of shape.

Earth loads are at the top of a seven-point list of casing damage mechanisms offered by George King, a HFTC panelist who is a completions engineering advisor with Viking Engineering, Six additional points are related to drilling and completions from the design and the materials used to crooked well paths and tight dogleg turns.

King said Viking has wells with doglegs in which the path downhole quickly changed by 25° to 35° within a length of a few feet. The weight of a long string of hanging casing can push pipe through a tight bend, but along the way it may also deform the tubular or store stress in it that may be activated during fracturing.

These tight turns are likely to be missed without a detailed well survey because the standard measurements-while-drilling reports measure changes over every 100 ft. The average of a sharp bend extending 3 ft in a run of 97 ft of straight pipe doesn’t appear so tight in the measurements.

Materials used in the well matter, including the sort of steel used in the pipe, the couplings, and the quality of the cement around the casing. These factors and the stress analysis used to design the well are put to the test during fracturing.

Rapid increases and decreases in the pressure and temperature can trigger forces that bend the casing. “The pipe is under stress and fracturing stresses right at the doglegs and cyclic-pressure-weakened areas may create pipe deformation during fracturing,” King said (URTeC 2902463).

That is not likely to cause heavier casing to fail, but if the force of the formation compresses the diameter by more than 5%—a fraction of an inch in most shale laterals—it may cause trouble during completions, he said.

For Further Reading

URTeC 2902463 Impact of Cyclic Pressure Loading on Well Integrity in Multi-Stage Hydraulic Fracturing by D. Barreda, M.P. Shahri, R. Wagner, and G. King, Apache Corp.