A strong reason for removing old platforms from the Gulf of Mexico, rather than trying to squeeze more years of marginal production out of them, is hurricanes.

Based on the damage left after a run of four hurricanes from 2005 to 2008, the cost of pulling a mangled structure from the seafloor “is six to 10 times what it would cost if the structure had not been toppled over,” said Don Stelling, president of Chevron Environmental Management Co., whose operations include decommissioning fields.

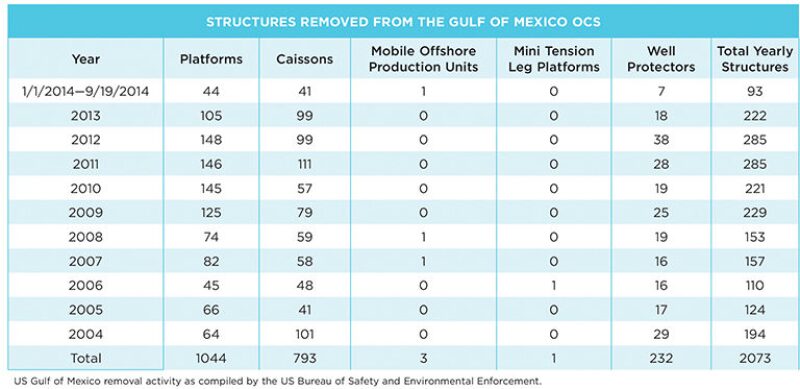

Hurricanes Katrina, Rita, Gustav, and Ike left Chevron with 30 platforms and 18 caissons to be removed in short order, along with 325 associated wells that needed to be permanently plugged. Over the next 6 years, Chevron upped the pace of removals. First, it needed to clean up after the storms. Then, in 2010, federal regulators put in new rules requiring faster removal of “idle iron” in fields that no longer were producing.

What was the cradle of new offshore drilling methods has now become a proving ground for how to remove platforms, caissons, and pipelines left from the beginning of offshore exploration and development.

Over the past 5 years, Stone Energy has worked off a large backlog of old fields. One plugged well, on a 36-pile structure in 50 ft of water, dated back to the 1940s, said Gary Siems, decommissioning manager for Stone. As the backlog of structures to remove rose—in part because of intense competition for vessels needed for the jobs after hurricanes—so did efforts by companies such as Chevron and Stone to find ways to reduce the risk and expense of plugging wells and removing old structures.

Chevron expects to use methods perfected in shallow waters. “There is technology developed in the Gulf of Mexico that we will use around the world,” Stelling said. On the horizon for Chevron is removing structures off the California coast, as well as in Indonesia and Thailand.

Chevron has supported development of new tools by service companies ranging from a long-distance audio warning system used to keep stray boats out of work zones to a new-generation dive boat without propellers. The propulsion system is designed to keep it on location without endangering divers. Its most productive partnership has been with lift company Versabar, Stelling said. The first was a floating truss spar floating on two barges known as the Bottom Feeder, which was created to speed salvage work by picking up wrecked equipment in large bites.

“The catalyst for the Bottom Feeder was the hurricane that toppled so many structures,” said Jon Khachaturian, president and chief executive officer of Versabar. “There was a big press on resources in order to get things done. They (operators) were a little more receptive to new technology.”

That evolved into the VB 10,000, an arched truss supported by two barges built to handle most shallow-water structures in a single lift, which has become the face of what is new in platform removals.

Because toppled rigs do not have handy points to connect cables for lift, it created the claw, which is used to grab large sections of damaged equipment from the seafloor. Now Versabar is working on a device to cut large supporting structures using a 2-in.-thick abrasive cable that looks like a giant hacksaw, which can cut through mud, steel, and concrete, eliminating the need for divers and speeding the time it takes to sever thick pipes and structures below the mudline.

Compressed Schedule

In 2009, Stone Energy had a backlog of roughly 100 structures to remove in the Gulf of Mexico, about one-third of which had been toppled by storms, and 285 wells it needed to plug. Initially, its focus was on plugging and removing nonproducing wells, Siems said. That allowed it to remove old well conductors. Removing these parts running from the wellhead on the platform to the seabed reduced the risk of toppling during hurricanes because conductors increase the stress created by high seas.

By 2011, Siems was looking for a way to get a lot of structures removed in a relatively short period. He was thinking along conventional lines until he learned about a new class of lift boat—a 290 ft-long, self-elevating barge used for offshore construction work—being built by Montco Offshore. The new one has legs that are 335 ft long and can work in water depths as shallow as 18 ft to as deep as 280 ft, and was billed as the world’s largest.

While others saw a large untested vessel that cost more, Siems said, “I jumped right on it. It was exactly the tool we could use knowing the scope of work before us.”

The bigger lift boat offered the work space and cabins needed to accommodate the nearly 80 workers within multiple teams. That offered the living and working space to do multiple services simultaneously. This marked a break from the normal approach of doing tasks sequentially, compressing the schedule from months to days.

The productivity of teams operating on Montco’s large lift boat justified the higher cost. “Most operators think of it in terms of the daily cost” of offshore services, Siems said. “I thought about it based on how much work we could do in a day by eliminating multiple mobilizations of different equipment spreads.”

One advantage of working in the Gulf of Mexico is that operators have plenty of jobs to do, providing them with many opportunities to perfect their systems. Joseph Orgeron, chief technical officer for Montco, which provides both lift boat and decommissioning crews to Stone, said it took a couple months for teams to figure out how to coordinate and optimize the effort when doing simultaneous operations.

Within 20 months, Siems said 80 platforms were removed and 148 wells were plugged by crews that worked 420,000 hours without a recordable accident. That was recognized by the National Ocean Industries Association, which awarded Stone Energy its 2012 Safety-in-Seas Award.

Now, Montco’s fleet includes a second 335 class lift boat. And Orgeron said that all the vessels in its fleet are working at a time when demand overall is off. “There actually have been quite a few lift boats docked. Fortunately, not any of ours,” Orgeron said.

Rethinking Removals

Enormous vessels are the symbols of change, but their value depends on the performance of those planning, managing, and executing the projects. Simply employing the newest tools and technology is not enough, said Brian Twomey, managing director of Reserve Engineering, a consultant in this area. “You can use the same tool in four parts of the world with four different crews and get different results. It is not just technology, you have got to have training to apply it.”

While explaining how change is managed at Chevron, Stelling regularly refers to Lean Six Sigma, a statistically driven system for identifying waste in a variety of forms, from downtime to inefficient use of equipment. It was used at Chevron to save millions of dollars when the company realized it could use its workboats in the Gulf of Mexico for both production and decommissioning, rather than maintaining separate fleets. Its operations center in Covington, Louisiana, created a system to better coordinate the assignments.

For Stone Energy, an essential part of its system is using the same experienced hands regularly. Siems said the ideal person for doing these jobs has the experience to quickly analyze the cause of a problem and knows whether to take action or ask for help.

Planning is required, but there is a point of decreasing returns. An engineer who painstakingly maps out each step will be frustrated by the unanticipated issues that are the norm in his sort of work. “In decommissioning, the work plan for today is very likely going to be different when executed tomorrow,” Siems said.

“Our people have been in the field a long time and we have empowered them to make decisions. We have contractors that have been working for me for 4 or 5 years,” he said. “The level of trust allows them to make decisions at the field and project manager levels without having to call me every time something unexpected happens.”

Trying to maintain centralized control over many decisions can lead to delays and increase costs, Siems said, adding that “for many companies, organizational change would be necessary in order for them to take full advantage of the model” employed by Stone Energy.

But success does require a foundation of good data. Big lifts require knowing, among other things, how much something weighs, how the mass is distributed, are there good connection points for cables, and can the structure stand up to the lift.

That requires an accurate diagram of the structure. That normally would be based on the original design drawings, but old fields often have been sold several times and original paperwork has been lost. Over its lifespan, a structure has been modified to meet the changing needs of the operation, has likely rusted, settled, and been battered by storms.

Precisely observing the condition of structures below the water line presents problems that have driven the development of new technology. Chevron has been an early user of an autonomous underwater vehicle made by Lockheed Martin equipped with sonar. It maps the dimensions of structures on a GPS grid to create a precise 3D model showing details like beams that are bent or thinned by corrosion. Stelling said the goal is to “make sure you have a picture of what is under water before you go to work to identify the risks and the condition of facilities in place.”

Versabar uses drones to film its lifts. That can prompt a later discussion about what went right and what could have been done better, Khachaturian said.

The number of things that can go wrong is staggering. Reverse Engineering Services has created a 12-step planning system. The list of things to consider was so long that Twomey said a financial executive with a major oil company was “shocked about the work involved.”

Planning for the end ought to begin as projects are conceived, said Alan Stokes, global decommission manager for WorleyParsons. A failure to consider the cost of future work can be costly. For example, early subsea wellheads were not designed to allow for entry by wireline devices, sharply increasing the cost of plugging one, said Stokes, adding, “New building design can reduce decommission costs.”