ADNOC has approved a $15-billion next step toward reducing the carbon footprint of its hydrocarbon-driven economy.

The plan, aimed at “future proofing” its oil-driven economy, builds on initiatives that have made it a pioneer in carbon capture in the Middle East.

A key part in the next stage of its decarbonization is a second carbon capture and storage (CCS) project, described as a “first-of-its kind.” ADNOC plans to increase its CO2 capture capacity to 5 million metric tons a year. And the capture and storage will help the country’s carbon-intensive industrial sector take the carbon out of its products by going blue.

The steps are significant, but the need for carbon capture and storage in the Middle East and globally is staggering, with the International Energy Agency calling for a 100-fold increase in carbon capture and storage alone.

Currently, the Middle East is home to 10% of global capture, with facilities in Abu Dhabi, Saudi Arabia, and Qatar, but is the major supplier of the hydrocarbon fuels blamed for a large portion of the emissions that are linked to global warming.

Abu Dhabi’s approach was aptly described by Sultan Ahmed Al Jaber, UAE Minister of Industry and Advanced Technology and ADNOC Managing Director and Group CEO, as “both pro-growth and pro-climate, and ADNOC is delivering tangible actions in support of both these goals.”

In other words, Middle Eastern companies are working to make affordable carbon-reduction investments that enable them to continue to capitalize on their enormous hydrocarbon wealth.

Abu Dhabi holds a small slice of those reserves, so its plan also focuses on becoming a carbon-reduction technology center in the region.

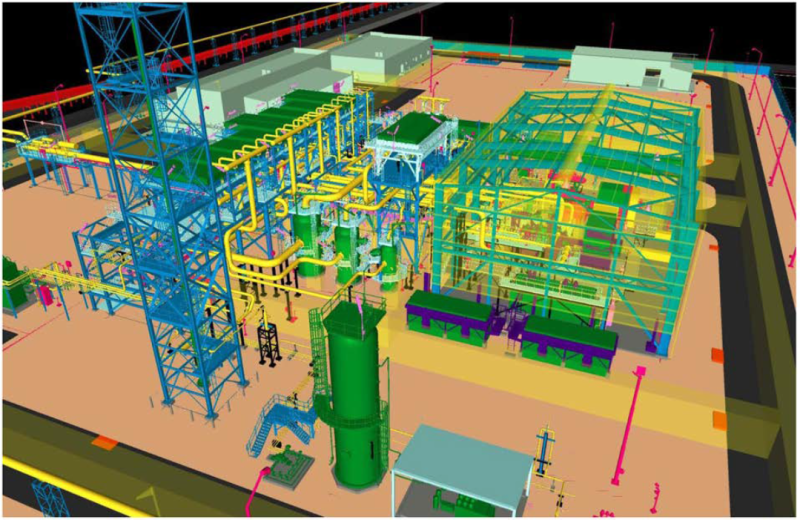

Currently, ADNOC is only capturing 0.8 million tons of CO2 per annum (mtpa) from a steel plant, which was a first-of-its-kind system that removes 90% of the CO2 from the emissions of the Emirates Steel production facility. The CO2 gas is pumped offshore where it is used to maintain the pressure in two offshore fields and increase their production.

The payoff for that capture project is not just the barrels added. CO2 injection allows ADNOC to replace natural gas which had been injected into those fields for that purpose, instead allowing it to be used in higher-value applications, as described in SPE 207676.

ADNOC has announced two more expansion phases that will add 5.0 mtpa of CO2 capture before 2030. Two announced sources of CO2 are expected to be the Shah sour gas plant, supplying 2.3 mtpa, and 1.9 mtpa from the Habshan natural gas processing facility, according to a recent report from the Global CCS Institute.

While the Middle East and North Africa region ranks behind the Americas, Asia Pacific, and Europe in capture, the Global CCS report said its potential is huge.

“With current carbon capture facilities, industrial facilities, available natural CO2 sinks, and future plans in the GCC [Gulf Cooperation Council] countries, the GCC countries could be a world-class hub for CCS,” the report said.

The announced plans are in line with moves by chemical makers around the world to use CO2 injection to reduce their carbon footprint.

Among the future sources of captured gas in Abu Dhabi is an ammonia production facility in Ruwais. The ADNOC statement said that the company, TA’ZIZ, plans to become a major producer of blue ammonia, which means the natural gas produced as part of that process will be stored in the ground rather than emitted.

The company has sent early blue ammonia samples to Europe for testing. Ammonia is being talked about as a possible low-carbon replacement for diesel in ships.

This is part of a global trend. The CF Industries plant in Donaldson, Louisiana, has announced a deal with ExxonMobil to permanently sequester 2.5 mtpa of carbon. It is the first of many such projects in Louisiana planned by chemical makers looking to improve their environmental scores.

Another common thread around the world is that these are long-term projects with actual operations coming on line years out in the future.

They are responding to pledges by government leaders around the world, including those in Abu Dhabi, to become carbon neutral by 2050.

But carbon-reduction goals have rarely been met and carbon-neutral products cost more. For example, the cost of a kilogram (kg) of ammonia made in the Middle East is less than $1.00—the lowest cost globally–while it estimated that blue hydrogen will cost nearly $1.50/kg and estimates of green hydrogen made using renewable energy and water are $6.00/kg.

Abu Dhabi ammonia makers are studying green while the country is investing in renewable and nuclear energy plants that do not emit carbon.

“Since January 2022, ADNOC has received 100% of its grid power supply from Emirates Water and Electricity Company’s (EWEC) nuclear and solar energy sources, making it the first major company in the industry to decarbonize its power at scale through a clean power agreement of this kind,” the announcement said.

The plan includes a $3.8-billion deal to build subsea transmission lines to offshore facilities, which it said it will reduce its emissions there by 50%, as the oil industry there works to eliminate flaring.

All of which could provide opportunities for services companies and industrial suppliers around the world.

The statement concluded by saying: “ADNOC is working closely with its international partners and stakeholders across the energy value chain to collaborate on technology, best practices and policy to support and drive global decarbonization efforts.”