The short answer for how to judge proppant strength sounds simple—just ask for the K-value.

The K refers to the weight in thousands that a sand sample can withstand in a crush test defined by API STD 19C covering “testing sand used in hydraulic fracturing operations.” For example, a sample that passes an 8,000-lb crush test but fails at 9,000 lb is an 8-K sand.

The goal of the standard is to measure how much weight a sand sample can withstand when used to prop open fractures to allow oil and gas to keep flowing. But a recent paper argues that measuring sand strength by the number of fines—small grains created by crushing—is an erratic indicator.

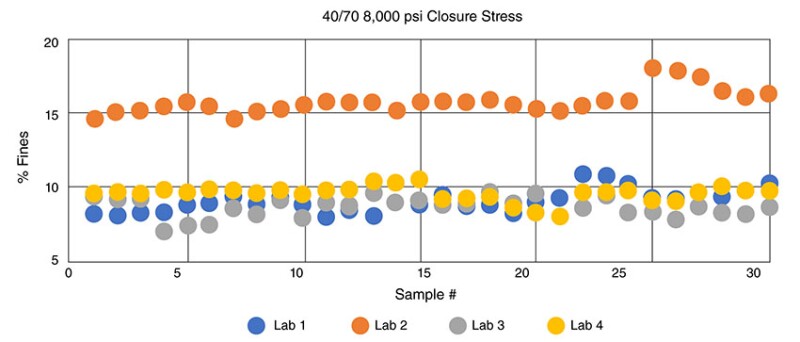

The SPE paper delivered at the 2024 SPE Hydraulic Fracturing Technology Conference described a blind test where a Permian sand supplier, Atlas Energy Services, sent out 120 samples of variously sized sand grains to four testing labs. The results for identical samples varied widely, even within the testing labs (SPE 217767).

“We are seeing 2K to 3K variation internally at independent labs on split samples, and at least 3K variation between labs,” said Ian Renkes, the paper’s lead author who is regional continuous improvement manager for Atlas in the Permian, adding, “This makes it very difficult if not impossible to differentiate between sand providers.”

For Atlas and other sand mines competing for business by focusing on delivering quality sand, this is frustrating because the inconsistent testing undermines those efforts.

There was an interesting detail near the end of the paper suggesting a large operator also has concerns. The list of references began by crediting “Todd Cage of ConocoPhillips who performed the initial work that provided the basis of this paper.”

Cage, ConocoPhillips’ commercialization manager in Midland, did not comment, but his role in devising the test suggests more than a passing interest in sand testing.

Keeping It Secret

For the test, Atlas created large samples in three mesh-size ranges—30/50, 40/70, and 100-mesh (40/140), using sand mined and processed in Kermit, Texas.

Each of them was measured 30 times using the API 19C methodology.