The lifespan of a huge, old oil field in Oklahoma is now linked to a fertilizer plant 68 miles away. Chaparral Energy is capturing 45 million ft3/D of carbon dioxide (CO2) that had previously been vented into the atmosphere in Coffeyville, Kansas, compressing it, and sending it via a pipeline to the Burbank field in Osage County, Oklahoma.

If the USD-250-million project works as planned, Chaparral will revive a field that looked to be near the end, with wells producing more than 99% water, adding a projected 80 million bbl more of oil production.

This is the biggest project for the company that is filling a hole in the CO2 supply map in the middle of the United States by building a CO2 supply system based only on industrial sources for enhanced oil recovery (EOR). Chaparral’s 380-mile long system connects three fertilizer plants and an ethanol plant with fields where it has EOR projects.

The goal is a longer life for marginal oil fields, said Keith Tracy, director of CO2 Midstream at Chaparral. “We have dozens of additional fields on the drawing board.”

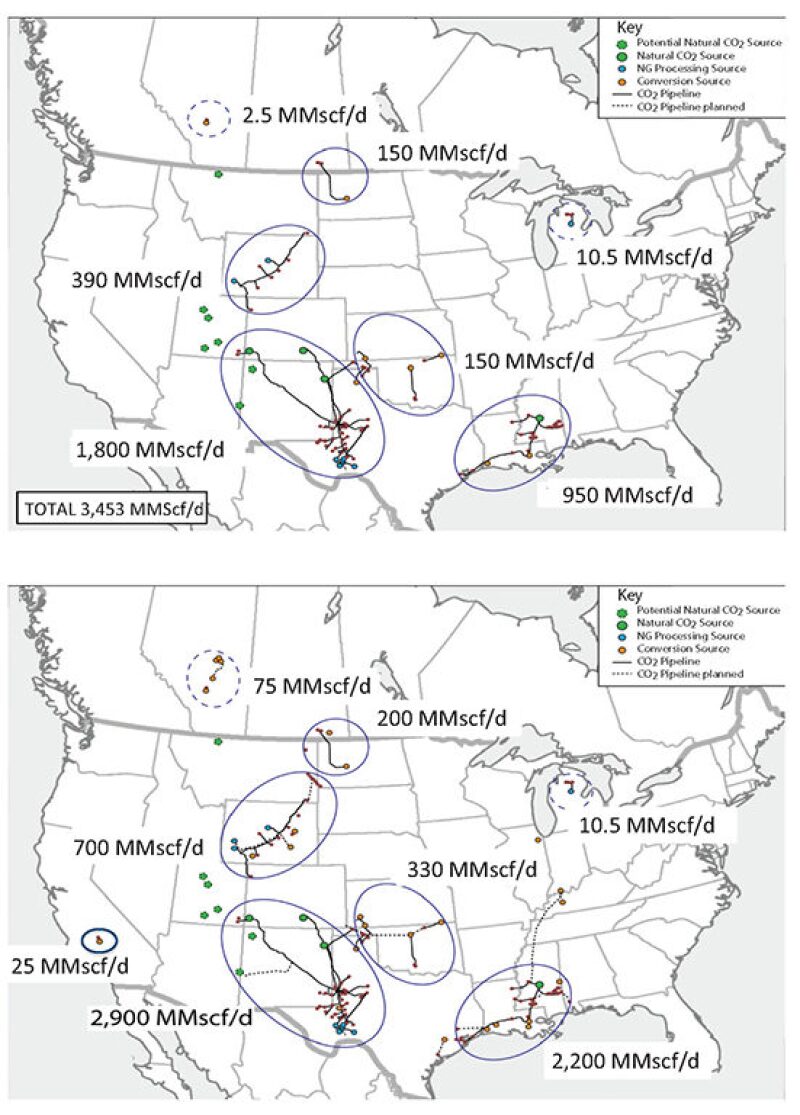

Those plans depend on finding more CO2. For Chaparral, and for the industry as a whole, industrial sources appear to be the most promising growth option. A nearly sevenfold expected rise in CO2 captured from industrial waste streams is expected to account for more than half of the 86% increase in US CO2 supplies over the next 5 years, according to a study by Phil DiPietro, strategic planner at the National Energy Laboratory of the US Department of Energy (DOE), and Glen Murrell, a research scientist at the Enhanced Oil Recovery Institute of the University of Wyoming.

“They (Chaparral) are the company that looks like other companies will look like over time,” in CO2 EOR, said Michael Moore, who led the CO2 EOR Carbon Management Workshop and leads the trade association representing those doing conducting CO2 EOR, the North American Carbon Capture and Storage Association.

The now small supply of CO2 for EOR from man-made sources—anthropogenic CO2—is expected to grow far faster than natural CO2, which is produced in nearly pure form from wells tapping ancient volcanic sources.

By 2020, the two sources are projected to be equal, but a lot of work and innovation will be required to turn that potential into a reality. The biggest source of industrial gas growth is said to be the US Gulf Coast, where there is a wave of petrochemical plant expansion aided by low US gas prices, said Vello Kuuskraa, president of Advanced Resources International, a geology and engineering services firm that makes regional CO2 EOR forecasts.

The study looked at existing and planned facilities with CO2 as a byproduct along Denbury Resource’s Green Pipeline, a pipeline that runs past the many refining and petrochemical plants along the coast of Louisiana and southeast Texas. The pipeline handles both naturally produced CO2 from the Jackson dome in Mississippi and gas that is a byproduct of plants along the coast.

“There is huge growth expected in the Gulf Coast,” Kuuskraa said. “That is the vision and the direction that this industry is headed.”

Growth in industrial CO2 supplies is also predicted in the midcontinent area, where Chaparral began injecting gas last June into the North Burbank unit, which is where the mineral rights are held by the Osage Indian tribe in northeastern Oklahoma. Chaparral’s plan predicts that adding CO2 will push production there from 1,200 to 12,000 B/D, according to a company presentation.

The company, which also develops unconventional oil reserves, projects that CO2 EOR projects companywide will grow from 4,000 B/D now to more than 35,000 B/D in 2020. Its growth requires finding industrial sources near fields where CO2 injections are likely to be effective. The economics of CO2 EOR put a strict ceiling on how much operators can afford to pay for the gas, which limits how far it can be shipped.

“There is a massive resource identified in mature oil fields that can take more CO2. The trick is more CO2,” Moore said. “In all cases, the next path for CO2 growth is captured CO2.”

No Easy CO2

The biggest potential industrial source of the carbon dioxide by far is coal-burning power plants. It is also one of the more expensive sources. The price is commonly estimated at twice or more than the USD-40/ton price commonly cited as the highest operators can afford for EOR, based on little experience.

Most of what is used for EOR now is from wells producing nearly pure CO2, which are concentrated either in the US Rocky Mountains or in the southern state of Mississippi.

Active drilling programs by the two largest CO2 suppliers, Denbury and Kinder-Morgan, are also expected to increase the amount from natural sources because supplies are limited for their& customers and their EOR projects.

“We had some pro-rationing earlier this year (2013) in the Permian Basin,” said Doug McMurrey, vice president of marketing and business development for Kinder Morgan CO2. It is drilling CO2 wells to increase its already high levels of deliveries in West Texas.

Kinder Morgan sells 60% of its CO2 to customers and uses the rest for its EOR operations, making it a major oil producer in Texas. And when there are curtailments, McMurrey said, Kinder Morgan’s fields are treated the same as third-party buyers.

The CO2 EOR business was built using reserves found and developed decades ago during the oil boom that ended in the early 1980s. The cost of bringing on a new generation of CO2 wells is forcing users to consider whether they can live with higher carbon dioxide prices.

“All the sources are more expensive than in the past,” McMurrey said. This is causing resistance. He said there have been customers who claimed to be “desperate” to find more carbon dioxide who said they could not sign a deal when they saw the terms.

Big, Costly Supplies

The biggest sources of smokestack CO2 are ones where the carbon dioxide is mixed with gases no one wants to inject in an oil field, requiring separation methods that are costly and have been little used in power plants.

To show that it is possible and how much large-scale operations actually cost, the US DOE has funded demonstration projects. There are proven methods for separating carbon dioxide from industrial emissions, but the cost is often an issue.

One of the larger grants went to Air Products to retrofit a unit supplying hydrogen to a Valero refinery in Port Arthur, Texas, to capture CO2. After two steam/methane reforming gas modules were replaced, the unit now is able to capture 90% of the CO2 produced in the gas-separation process. During its first 6 months of production, it produced 500,000 tons of carbon dioxide, which it delivered to Denbury’s Green Pipeline.

Government support covered USD 284 million of the USD 431-million cost, which included a 30-MW unit to power the operation. “This process does not make sense without DOE support,” said John Palamara, development manager for research and development at Air Products and Chemicals, in a presentation at the conference.

In Kemper County, Mississippi, a coal-fired power plant being built by Southern Company will be equipped to capture nearly two-thirds of the CO2, which will be used for EOR. It also will produce and sell ammonia and sulfuric acid to help offset the cost of CO2 capture.

Capturing carbon dioxide means the plant would emit less of it than a natural-gas-fired plant, which would put it under the emission limits proposed by the US Environmental Protection Agency for new coal plants.

But this demonstration, backed by USD 270 million from the US DOE, has become a cautionary tale. The electric utility developed and tested the technology, but budget overruns have pushed up the cost of the plant, coal mine, and pipeline to an oil field by USD 1 billion to USD 4.45 billion. Its opening date has been delayed until late 2014.

When asked about the overruns in an interview posted on Southern’s website, Tom Fanning, chairman and chief executive officer at Southern, said the budgeted cost was calculated early in the engineering process and only a 6% contingency was built in. Based on the cost per kilowatt hour of generating capacity, this plant could make sense in international markets where power costs significantly more than it does in the US, he said.

Another clean coal project, the Texas Clean Energy Project, has yet to begin construction. The plant in west Texas being developed by Summit Energy Group will use nearly half the 400-MW generating capacity to capture all its CO2 and turn it to make salable commodities. It will sell some of the gas for EOR and use the rest to make urea, which is used for fertilizer. The process also removes sulfur, which the plant will use to make sulfuric acid to sell. The project is supported by USD 450 million from the US DOE plus more than USD 673 million in tax credits—plus promises from state and local governments to reduce future tax bills.

As of yearend, Summit was still working on closing deals needed to begin construction, which was likely to continue in 2014, said Chris Tynan, vice president of project finance for Summit Power. Among the loose ends were final agreements with China’s Export-Import Bank and Sinopec, which are among the backers.

The surge in hiring related to the rapid rise in unconventional exploration in the sparsely populated region around Midland has pushed up the price of the plant. “The boom in the Midland economy has caused labor prices to increase. We are trying to navigate that at this time,” Tynan said during the CO2 conference.

Meanwhile, the US DOE is looking for ways to capture relatively clean streams of the gas that come from certain types of plants, such as those removing carbon dioxide from natural gas or makers of ammonia or ethanol.

“I think there is a good opportunity there,” DiPietro said. “There are early opportunities up and down the Gulf Coast” to add new industrial CO2 sources.

He has counted 18 projects in North America that could capture industrial and supply it for EOR. His goal is a DOE strategy backing development of methods to lower the cost of CO2 capture from industrial sources and allow operators to produce more oil per ton of CO2 injected.

CO2 Next

The enormous potential market for CO2 is attracting innovators with ideas about how to close the price gap. In mid-December, former US Energy Secretary Michael Chu became a board member for Inventys Thermal Technologies, a Canadian company with a method using a ceramic material that it says can capture CO2 for about USD 15 a ton. When other costs associated with compressing and delivering carbon dioxide are added, a company release said the price per ton could be from USD 40 to 50, which is near what is considered affordable for EOR. The company said it has yet to demonstrate it can do this in a large-scale test.

A group of technology developers from GE Research, working on lower-cost CO2 capture methods, also was at the CO2 conference.

Some companies at the conference presented ideas for using natural gas to create CO2. For these processes to be affordable, they must also produce power and sell it at a good price. One innovator on hand was Robert Zubrin, the chief executive officer of Pioneer Energy. The company was created to commercialize its Portable Enhanced Oil Recovery Technology, which turns natural gas into CO2 and hydrogen, which then can be used to generate electricity for sale on the grid.

The initial target audience for its units, which will be able to produce 500 Mcf/D of CO2, will be operators conducting field tests who now rely on tank trucks, which are expensive. For the process to be cost-competitive, Pioneer needs to be able to sell power for about USD 0.06/kW-hr, Zubrin said.

Maersk has licensed another technology that, like Pioneer’s, has roots in the space program. Its Trigen system burns natural gas with pure oxygen to produce CO2, electricity, nitrogen, and water. It can use low-quality field gas associated with oil production, which could reduce flaring.

“You can get to below USD 40/ton for carbon dioxide if you can get a reasonable power price,” of from USD 0.07–0.09/kW-hr, said Pieter Kaptejin, director of technical operations at Maersk Trigen, a venture that includes Siemens. “It changes the way you do upstream.”

So far, Maersk Trigen is in talks with a national oil company. A significant problem has been the complexity that comes with negotiating agreements to divvy up multiple income streams among partners. “The whole value chain creates a lot of value,” Kaptejin said. “But how do you distribute it (revenue) is the hard part.”