The Research Council of Norway has awarded a grant to Fishbones AS to assist in the next round of development of the company’s pioneering IOR (improved oil recovery) stimulation method aiming to extend the technology’s reach into tight reservoirs by 50%.

The $118,000 (NOK 1.25 million) award—part of an initiative to reduce emissions and raise efficiencies in the oil and gas sector—bolsters the company's joint work with Aker BP which holds a 17% stake in Fishbones AS and applies the technology at the Valhall field.

Aker BP holds a 90% operator stake in Valhall while Norway’s Pandion Energy controls 10%.

The concept (called “fishbones” because the laterals’ shape resembles a fish skeleton) was initially developed for an offshore field trial at Valhall from 2008 to 2012, according to Aker BP. But it was not until Aker invested in the technology’s creator Fishbones AS in 2017 that it began to include the method to raise production from Valhall’s soft, fine-grained chalk reservoir.

Norway has produced oil and gas at Valhall for 40 years, and Aker BP is currently working on a new central platform that the Norwegian operator will use to sustain production for 40 more years. To accomplish that, Aker BP has strategically invested in Fishbones AS to build up the portfolio of IOR technologies it will need, Per Øyvind Seljebotn, Aker BP’s senior vice president for exploration and reservoir development, said in a news release.

Equinor also uses fishbone technology on the Norwegian Continental Shelf and its corporate venture capital investment arm, Equinor Ventures (formally Statoil Technology Invest AS), holds a 25% share in Fishbones AS, according to PitchBook, a market analytics provider.

Knitting Reservoir Layers Together With Acid-Spewing Needles

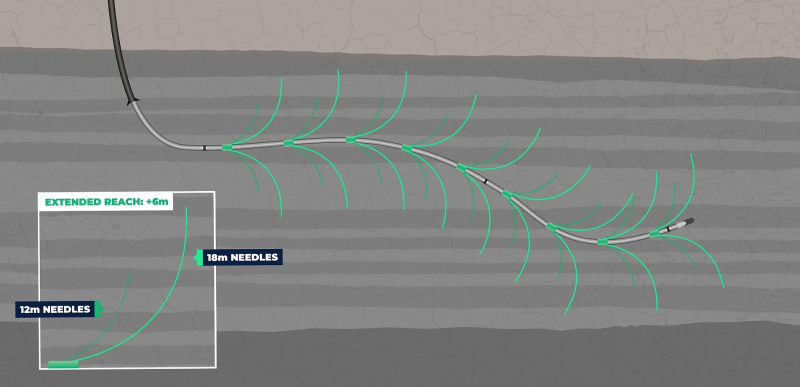

Conceptually, fishbones technology comprises an uncemented-liner, rig-deployed completion stimulation system with fishbone subs placed in the liner at fixed intervals. Each sub consists of four high-strength, small-diameter needles that connect the sublayers by penetrating into the formation with acid-jetting nozzles on the front end.

The current focus of the technology’s development is to enable the titanium needles to extend up to 18 m in length (as opposed to their current 12-m limit), thus growing reservoir reach by 50% and creating a corresponding increase in the effective drainage radius of the wellbore; an increase in connectivity with any natural fractures; and greater penetration through natural formation fluid flow barriers, according to the companies involved.

Commenting on the grant award, Fishbones AS CEO Eirik Renli said in a news release, “We are excited to embark on our co-funded development project with Aker BP and grateful to be one of 15 companies to receive funding from The Research Council of Norway.”

ADNOC Applies Fishbones in the Middle East

ADNOC applied fishbones technology for the first time on the UAE offshore in a pilot well in 2016, after having successfully used the method onshore. At the 2022 International Petroleum Technology Conference, the coauthors of IPTC 21959 (ADNOC, Fishbones AS, and ADNOC R&D) reported that a second ADNOC offshore well experienced a 150% production uplift after issues arising in the earlier pilot were addressed.

Among those adjustments were

- Adoption of multilateral acid-jetting technology as a more-effective approach to typical drainage methods and improved vertical connectivity.

- An alternate approach to creating new connections between layers previously separated by very tight, low-permeability barriers in carbonate reservoirs, thus overcoming the limitations of conventional stimulation techniques which often leave significant volumes of recoverable reserves out of reach.

- Redesign of the needle cleanout tool; acid-activated float shoe and production valve had also occurred.

The laterals create “a permanently installed lower liner with fullbore access to total depth,” the authors wrote. This reduces the number of wells required while simultaneously increasing recoverable reserves, thus placing fishbone multilateral acid-jetting technology “at the forefront of facilitating the future state of field development,” they concluded.

In another case study, ADNOC Offshore, Halliburton, and Fishbones AS applied a new real-time petrophysical data acquisition program using logging while drilling (LWD) to estimate the proportion of connate saturation and free fluid distributions along a horizontal well section in a tight carbonate reservoir.

The companies presented their results in SPE 212662 at the 2023 SPE Reservoir Characterization and Simulation Conference and Exhibition.

With the help of LWD, the authors successfully characterized fluid distribution saturation and predicted permeability to better determine the depth of perforation for stimulation and optimize lower-completion design. This allowed them to select perforation intervals for the fishbone simulation efficiently.

Optimizing Well Productivity Forecasts With Machine Learning

With the maturation of fishbone technology generally, fine-tuning the optimal geometry of a fishbone well path has now caught the attention of the machine learning community.

Paper ARMA-IGS-2023-0141, presented at the 2023 International Geomechanics Symposium, highlighted how machine learning can facilitate the design of fishbone geometry by selecting the number of branches, their directions and lengths, angles between the main hole and microhole, and inter-fishbone distances among other things.

After assessing machine learning algorithms such as Random Forest, Gradient Boosting, Linear SVC, AdaBoost, and K-Nearest Neighbors, along with various modeling metrics, the researchers from Texas A&M University, the University of North Dakota, and Ecopetrol concluded that bottomhole pressure presented itself as the most consistent predictor of fluid flow rate in optimizing fishbone drilling designs.

FOR FURTHER READING

IPTC 21959 Multilateral Jetting Technology Results in a 150% Uplift in Production During a Second Offshore Application in Abu Dhabi Offshore Field by Salman Farhan Nofal and Fazeel Ahmad, ADNOC Offshore; and Ahmad Shmakhy, ADNOC R&D, et al.

SPE 212662 Improved Reservoir Characterization of Tight Carbonate Rocks Using Multiple High-Resolution Logging-While-Drilling Technologies for Completion and Stimulation Optimization With Fishbone Technologies: A Case Study From Offshore Abu Dhabi by Sundos Al Abed, Hocine Khemissa, and Susumu Kurokawa, ADNOC Offshore, et al.

ARMA-IGS-2023-0141 Optimizing Fishbone Multilateral Well Productivity Forecasting With Machine Learning Techniques by Henry Galvis Silva and Oliver Rojas Conde, Texas A&M University; and Houdaifa Khalifa, University of North Dakota, et al.