A US operator is using Actenum’s DSO/Upstream scheduling software to improve drilling program efficiency, adding $510,000 to annual earnings.

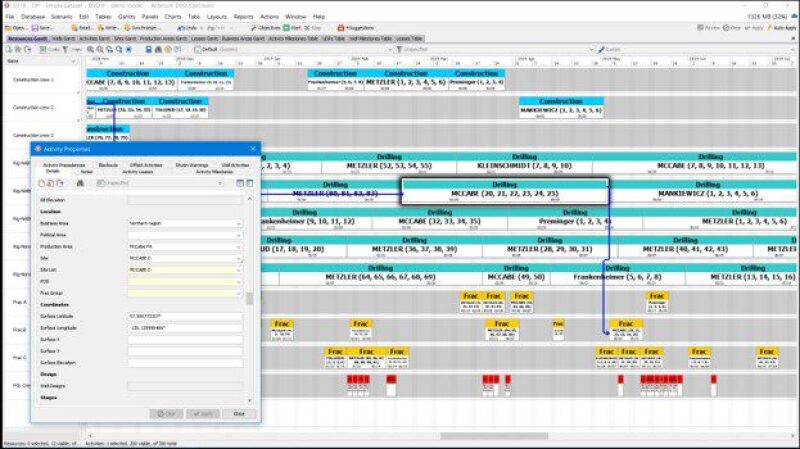

The operator uses Actenum DSO/Upstream for integrated well lifecycle scheduling, incorporating all activities and milestones from permitting to putting new wells online. Most of the financial benefit results from Actenum DSO/Upstream’s automatic optimization and scenario evaluation capabilities.

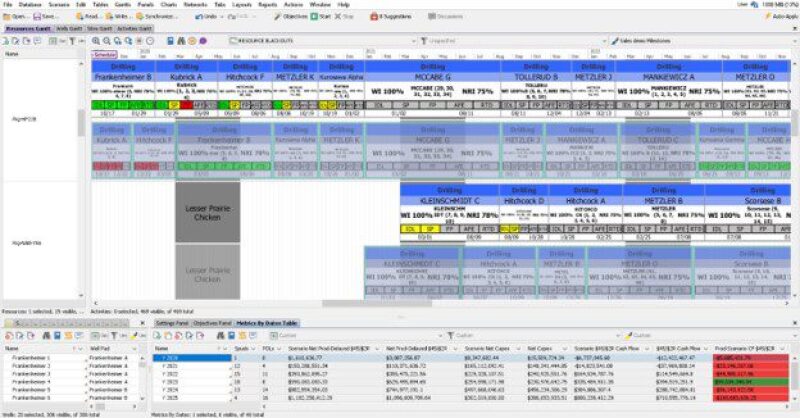

The software rapidly optimizes the entire drilling project activity sequence, according to objectives and constraints that the project team derives. Each separate optimization run is saved as a scenario and compared to other scenarios, enabling the team to select the best one at any point.

The Need for a New Scheduling Tool

In 2015 it became very clear to the operator that, as they had grown by acquiring acreage, they had also outgrown their existing spreadsheet-based scheduling tool. Besides being cumbersome and unreliable, it didn’t provide any easy way to evaluate schedule scenarios to determine the impact on capital and production of adding or redeploying rigs. Schedulers had to perform multiple iterations of painstaking manual manipulation to analyze outcomes.

As well, to promote collaboration, master schedules were kept on a central MS-SharePoint server. But downloading and opening the spreadsheet-based schedules was very slow, forcing some planners to rely on colleagues for updates, instead of simply reviewing the latest schedule version. Because the tools were spreadsheet-based, the schedulers could not rely on automatic quality control over regulatory stipulations or resource allocation. Frac and drilling schedules were separate from each other, and from construction schedules, so identifying all resource requirements and timing was difficult, leading to schedule conflicts, poor productivity, and overscheduled resources. Long-term planning presented a significant challenge because considering all constraints, including permit times, material requirements, and facility construction durations, was simply too time-consuming. Comparing drilling schedule versions was difficult and laborious.

Financially Significant Consequences

Scheduling shortcomings didn’t just lead to frustration. They were causing serious red ink in the financial department. Planners determined that when changes were required as a result of a schedule conflict, an average of two extra rig moves were needed, along with other equipment redeployment. At an approximate cost of $60,000 per move, and an average of four major conflicts each year, $480,000 in overruns were adding to expenses annually.

In addition to physical resources, human resources were not optimally deployed. The team calculated that at least three people per week were wasting time because of poor scheduling, equating to over $30,000 in unnecessary costs annually.

Selection of a New Scheduling Tool

To staunch financial bleeding and make planning and scheduling more reliable, the operator looked for an integrated scheduling solution that would provide scenario capabilities and enable easy collaboration, as well as predict capital and production impacts. After an extensive evaluation of potential solutions, the operator determined that Actenum’s predictive scheduling solution, DSO/Upstream, provided everything they were looking for, in a feature-loaded, flexible software tool.

Actenum DSO/Upstream incorporates permitting, approval, construction, facilities, drilling, fracking and production activity timing in one integrated schedule, while honoring resource availability and regulatory constraints. The tool provides both optimization and scenario analysis to meet the operator’s goals to grow and maximize profitability.

Using DSO/Upstream, the operator has improved planning by incorporating all relevant pre-drill events into the drilling scheduling process. Scenarios include what is feasible to accomplish over the full well life cycle, not just for drilling. The team is also able to estimate production forecasts accurately by including type well information.

As well, DSO/Upstream is assisting the planning team in assessing future acquisitions and new business unit starts. Planners are now able to see in advance whether new business plans are executable and financially advantageous.

The operator is also using Actenum’s DSO/CX product, which provides up-to-date schedule information to all team members in a web browser.

Additional Benefits

Besides the $510,000 earnings improvement obtained from Actenum’s software, the operator has improved their well delivery scheduling process, and expects to see a reduction in time to first oil as they continue to drill as part of their growth strategy.

A Demo of Actenum DSO/Upstream

Click here to request a demonstration.