Casing deformation has become a significant challenge in the development of shale gas reservoirs, particularly in China, the Middle East, and North America.

This issue is particularly an issue in unconventional completions, where the combination of geological complexities and operational demands often leads to wellbore-integrity problems. The deformation of casing, often referred to as "casing deformation" or "casing ovality," can severely impact the efficiency of plug-and-perforation operations, leading to increased nonproductive time (NPT) and compromised well productivity.

The root causes of casing deformation are multifaceted, involving both geological and engineering factors. Geologically, shale gas reservoirs are characterized by low permeability, high brittleness, and significant natural fracturing. These characteristics make the formations susceptible to deformation under induced stress during hydraulic fracturing operations. The high-pressure injection of fracturing fluids can reactivate natural fractures or faults, leading to shear slippage that causes casing deformation.

Additionally, the complex geological structures in deep shale-gas reservoirs, such as those in the Sichuan Basin in China where the case study was executed, further exacerbate the risk of casing deformation due to the higher incidence of faulting and fracturing.

From an engineering perspective, wellbore cooling during fracturing operations can significantly reduce the casing's collapse strength, making it more susceptible to deformation. Poor cementing quality can result in inadequate support for the casing, leading to stress concentration and eventual deformation. The design and selection of casing strings also plays a crucial role in mitigating deformation risks.

To address these challenges, the industry has been exploring innovative solutions. One such solution is the development of high expansion dissolvable plugs (HEDPs), which are designed to expand significantly while maintaining high pressure ratings. These plugs can navigate through tight spots in deformed casings, providing reliable temporary isolation and reducing the risk of operational failures. Additionally, optimizing pumpdown procedures and using specialized tools like the pumpdown ring can enhance the efficiency of plug deployment and minimize water usage.

Design of the HEDP

The structural design of the HEDP is engineered to maximize efficiency and effectiveness in challenging downhole environments (Fig. 1). Utilizing high‑elongation dissolvable metals, the HEDP features a single slip design, which significantly reduces the overall plug volume. This compact design enhances the plug's ability to navigate tight spots in the wellbore and ensures quicker dissolution post-fracturing, minimizing NPT.

The slip teeth are constructed from high-strength, hard ceramic materials, which not only provide anchoring but also facilitate smoother passage during subsequent milling operations compared to traditional alloy teeth, reducing the risk of damage to milling tools.

For sealing, the HEDP incorporates either a metal seal or an element seal, depending on the specific application requirements. Once set, the HEDP firmly grips the casing, creating a reliable seal that enhances fracturing efficiency by preventing fluid leakage and ensuring optimal pressure transmission. To address the challenge of low pump efficiency for small-diameter plugs, the HEDP is equipped with a pumpdown ring. This innovative feature assists in the pumpdown operation, saving time and reducing water usage.

Most notably, the HEDP features a patented spiral design on its body. This unique structure allows a small-diameter plug to effectively anchor in larger-diameter casings, providing a secure and stable platform for fracturing operations.

Pumpdown Efficiency

In the application of small outside-diameter (OD) frac plugs in large OD casings, a significant challenge arises due to the insufficient pumpdown thrust, which often results in the inability to efficiently pump the plug to the set depth of frac plug.

This inefficiency is particularly pronounced in shale gas wells with casing deformation where the reduced cross-sectional area increases fluid resistance and decreases the efficiency of the pumping operation, thereby prolonging the entire fracturing process and leading to a waste of water. To address this challenge, an innovation has been developed by incorporating a dissolvable pumpdown ring into the frac plug design.

This pumpdown ring made of dissolvable rubber, strategically mounted on the plug body or wireline adapter kits, significantly enhances the pumping thrust by increasing the effective cross-sectional area for fluid flow. The dissolvable nature of the ring ensures that it does not interfere with subsequent operations, as it will be dissolved and out of the way after the plug has been successfully positioned and fractured. This enhancement not only improves the pumpdown efficiency but also further reduces the risk of operational delays and NPT in challenging wellbore scenarios.

Pressure Holding Test

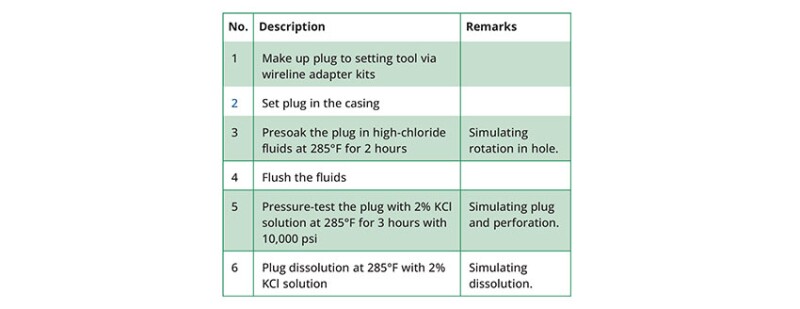

The development and deployment of the HEDP represents a significant advancement in addressing casing deformation challenges in unconventional well completions. However, before the HEDP could be confidently used in field operations, it was essential to conduct comprehensive indoor tests to validate its performance under controlled conditions. To verify the feasibility of HEDP in underground operation, an indoor test was conducted to simulate the underground environment of a well. The specific experimental process and results are shown in Table 1 and Fig. 2.

The pressure-holding test was designed to simulate the downhole environment of a well, using a 5.5-in., 26.8#, Q125-grade casing and a hydraulic Baker 10# setting tool. The HEDP plug, with an outer diameter of 3.11 in., was subjected to a surface pressure of 10,000 psi and a static temperature of 285°F.

The test procedure involved assembling the plug to the setting tool, setting it in the casing, presoaking it in high-chloride fluids for 2 hours, flushing the fluids, and then conducting a pressure test with a 2% potassium chloride (KCl) solution for 3 hours at 10,000 psi.

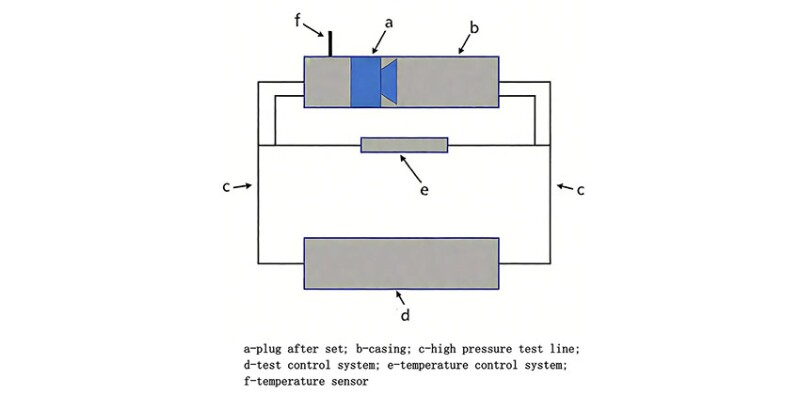

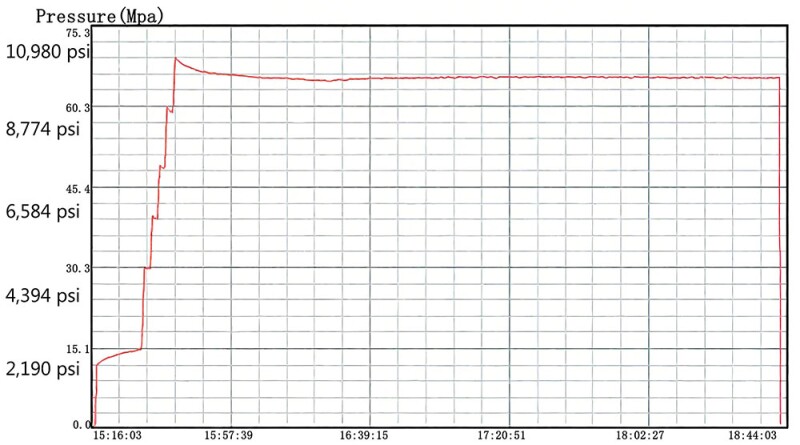

The results indicated that the HEDP maintained a pressure of 10,000 psi for 3 hours after a 2-hour presoaking period, with a pressure decline of only 568 psi. This demonstrated the plug's strong resistance to high temperatures and pressures, meeting the criteria for reliable performance in downhole conditions. The test system and pressure-holding curve are depicted in Fig. 3 and Fig. 4, respectively.

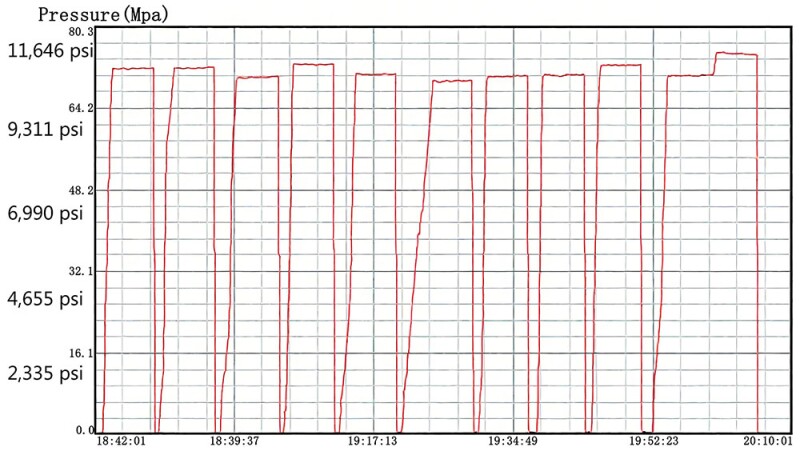

Additionally, the HEDP's seal configuration showed enhanced pressure-retention capabilities, withstanding over 10 pressure-cycle iterations. This capability is important for managing the varying pressure cycles encountered during different fracturing phases and enhances the safety margin during operations in highly compacted formations.

Field Applications

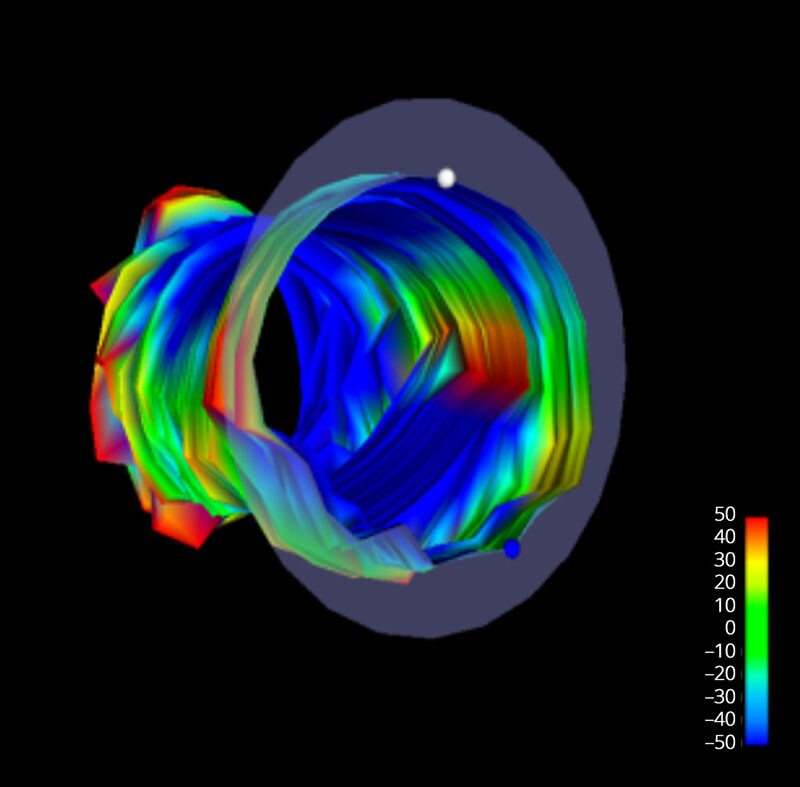

In this well, HEDPs were deployed with coiled tubing. The minimum internal diameter (ID) of the casing-deformation point of this well is 3.268 in. The multi-arm-caliper logging tool monitoring result is shown in Fig. 5.

HEDPs passed the casing-deformation point smoothly without encountering any resistance. During operation, the HEDP withstood a maximum pump rate of 88 bbl/min and a treatment pressure of 13,053 psi, showcasing its strong pressure rating. The reservoir below the casing change point of this well was fractured successfully by using HEDP, and the estimated ultimate recovery of this well was increased.

Following the fracturing process, the HEDPs were fully dissolved, flowing back without milling after the frac operation.

In conclusion, the HEDP has proven to be a reliable and efficient solution for addressing casing-deformation challenges in unconventional well completions. Its innovative design, ability to achieve high performance in harsh environments, and successful field applications demonstrate its potential to significantly improve operational efficiency and well productivity.

By incorporating technologies such as the HEDP into more operational strategies, the industry can expect enhanced productivity and more cost-effective completion outcomes in challenging downhole environments.

Shao Huazheng,has worked across multiple sectors of the oil and gas industry, including drilling, completion, workover, stimulation, and production. He previously worked at ConocoPhillips and Weatherford, gaining over 10 years of deep experience in unconventional resources development. Currently, he serves as the engineering manager for the unconventional completion and dissolvable technology unit at Vertechs Group.

Jin Ningjing, is a seasoned energy professional with extensive experience in oilfield completions and dissolvable technology. Beginning his career as a completions engineer with Halliburton, he later advanced through technical, project, and leadership roles at Vertechs Group, culminating as a Middle East regional manager. With a background in natural resource exploration and an MBA, he has led global teams across North America, China, and the Middle East, driving innovations in unconventional completions, dissolvable plugs, and field execution strategies.

Feng Li, is a certified cost engineer for the PetroChina Southwest Oil & Gasfield Company. She has extensive experience in completion, development, oil and gas gathering, and transportation engineering technology, and cost management in the petroleum and natural gas industry.