The discourse regarding US land exploration and production has tended to primarily focus on shale development. While this has pushed the industry to adopt many technologies or applications, the general recipe has been to be faster and cheaper with hopefully more predictable BOE/ft production. However, there are limitations with this approach as it tends to boil down to a choice of substitution rather than true engineering to improve return on investment or improved net present value.

The relationship of parent and child well production has introduced a variable that does not necessarily respond to faster and cheaper. In fact, operators may agree that a dissolvable frac plug has application to reduce completion costs while completely disagreeing on the methodology to manage field development and the parent-child interaction.

Extensive field study and calibration can determine an optimal solution with varying degrees of predictability (SPE 211899).

For example, reservoir depletion and fracture communication can be difficult to accurately plan for in advance. These and several additional parameters are specific to a section, field, or bench and the design and planning process begins anew when drilling locations move a sufficient distance away from the asset in question.

The best outcome during the drilling and completion of a child well is to limit the negative impact on parent well production while delivering an economically viable addition to existing production. Acceptable ranges of underperformance with the child well vary, but can be summarized as 20 to 30% less than the parent well (SPE 209171).

Additionally, contact from an offset child well fracturing operation can detrimentally affect parent well production temporarily or permanently by increasing water production and decreasing hydrocarbon production.

Introduction

This case study presents the development of a methodology for optimizing and controlling the hydraulic fracturing process’s parameters by increasing cluster efficiency to 100% and overcoming formation leakoff with eight to 10 times rate per cluster when compared with industry standards.

The developed framework is validated through field completion and production data taken from wells located on the Northwest Shelf, within the San Andres formation, specifically straddling the state line of New Mexico and Texas with operations primarily in northeast Lea County, New Mexico, and Yoakum County, Texas.

For the purposes of this study, parent wells are wells drilled during Segment 1 (2013 to 2016) and/or the first wells drilled in a section.

Child wells are defined as any subsequent wellbore placed in a section amongst current producers Segment 2 (2017 to 2020) and Segment 3 (2022 to 2023).

The offset true vertical depth (TVD) of the child wells relative to the parent wells is less than 100 ft and no geologic barrier exists, thus the contribution to production is from the same rock matrix regardless of well vintage.

Segment I: Drilling and Completion Operations (2013–2016)

Initial horizontal development in the San Andres experienced production coming online with high water volumes that in many instances exceeded 90% water cut. Legacy vertical well development identified the high water saturations, so this did not come as a surprise.

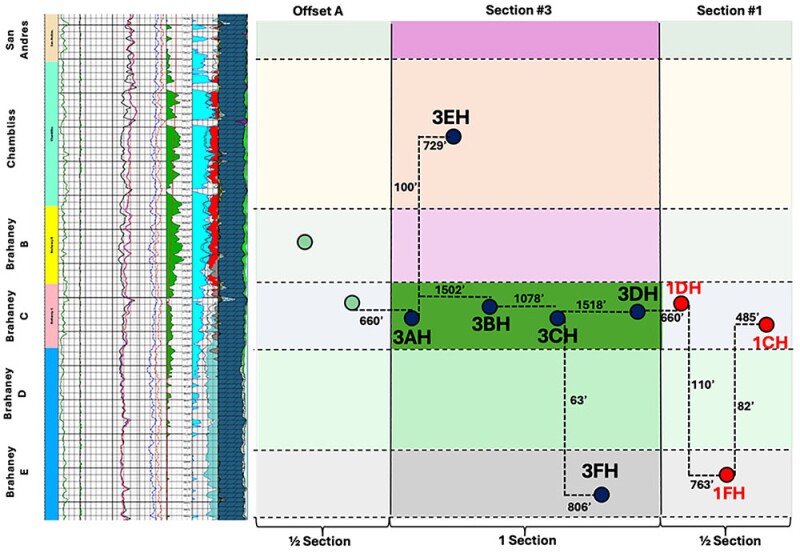

Where to land a horizontal well became the priority to hopefully reduce produced water volumes and improve economics. The general approach was to turn the bit 90° at the base of the Brahaney C bench within the overall San Andres formation and use a four-well “wine rack” (e.g., wells A-D in Fig. 1). This approach looked to take advantage of the frac height growth upward while keeping the well targeting the very bottom of the residual oil zone (ROZ).

Conventional plug and perf with a ball-drop mechanism isolated and prepped each stage prior to the frac stimulation. Frac designs built on the historical completion work in the vertical San Andres development. The design even included a gelled acid bullhead in front of the proppant schedule.

This is a good example of checking a box in fracturing theory as opposed to understanding the application and quality control environment. A 12# linear gel and 15# crosslink gel were the primary proppant carrying systems. The stimulation metrics are as follows:

- 383 lbm/ft and 11.7 bbl/ft @ 60 bbl/min

- 19% 100 mesh, 29% 40/70, 52% 30/50 sand

- 21 bpm/cluster

- 391-ft stage spacing (plug to plug)

Segment II: Drilling and Completion Operations (2017–2020)

Drilling operations focused on cost reductions and efficiency gains with no major changes in mud systems or procedures. Beyond these considerations, an impactful decision was made to ignore the common concern regarding lateral TVD and where to land the well.

The Brahaney D bench became the center of focus to conceptually improve the gross pay zone stimulation. Offset sections to that exhibited in Fig. 1 have single wells at TVDs between Wells A-D and Well F to test drifting away from the Brahaney C.

Conventional plugs were primarily used with some dissolvable plug testing. The low reservoir temperature (105°F) is not ideal for dissolvable plugs. Overall results were mixed, and composite frac plugs remained the preferred option.

The frac design made a shift towards a more hybrid approach by utilizing slickwater while also increasing near-wellbore proppant pack conductivity by adjusting the following criteria:

- 750 lbm/ft and 16 bbl/ft @ 50 bbl/min

- 3 to 5% 100 mesh, >95% 30/50 (thin bed design) or 20/40 (infill/child well design)

- Adjusting % of crosslinked fluid and gel loading, e.g., 18# or 12# instead of 15#

- 16 bpm/cluster

- 243-ft stage spacing (plug to plug)

Post-frac drillout operations were becoming a high-risk operation to forward circulate and effectively clean the wellbore with reservoir pressure being insufficient to maintain the hydrostatic pressure to maintain annular velocity targets. Unfortunately, the formation began taking so much fluid that another solution had to be implemented.

Segment III: Drilling and Completion Operations (2022–2023)

Promising results from Segment II wells led to disregarding conventional petrophysical analysis and landing wells shallower at the top of the ROZ in the Chambliss or deeper beyond the water/oil interface in the Brahaney D/E (these wells are labeled E/H in Fig. 1).

The decision was made to move away from isolating frac stages with plugs. Each well included the deployment of a multistage, single‑point completion system with fully dissolvable downhole elements.

The early execution and results in other sections indicated that pushing max pressure with max rate was more desirable for improving production. Direct collaboration with the completion tool service company allowed fracturing rates to increase over time from 35 bpm to 65 bpm and up to 95 bbl without compromising consistent frac stage execution.

Volumes deployed per well and cluster/perforation averaged as follows:

- 984 lbm/ft and 20 bbl/ft

- 100% 30/50

- >80 bpm/cluster (single point entry)

- 160-ft stage spacing (sleeve to sleeve)

Following the multistage fracturing treatment, a conventional workover rig was outfitted with a mule shoe with internal custom carbide teeth to wash down to the toe depth, minimizing fluid on formation while ensuring no restrictions were present in the lateral.

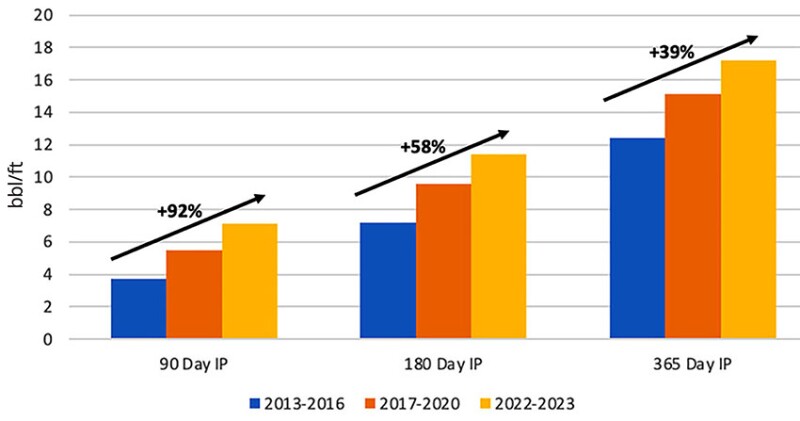

As per Fig. 2, the improvement over time is significant. The increase in production occurs despite the operator producing from the same formation, drilling the same lateral lengths, and deploying the same artificial lift over a 10-year period. All the while capturing a greater share of oil price trends.

Conclusion

The ability to outperform existing parent wells is a combination of allowing the propped fracture to access as much gross pay as possible and concentrating the fracturing properties into an extremely small window. It has been well documented publicly that fractures tend to grow upwards and take on a penny, or coin, shape.

The addition of gross pay was achieved by using the fracture-height growth tendency in combination with lowering the target zone to the lowest feasible point to exploit the San Andres formation.

Accessing more rock beyond the propped fracture height was accomplished by recreating the concept of an extreme limited-entry design and controlling frac propagation beyond conventional methods. The ability to control the fracture initiation in the near-wellbore region created a more productive fracture network in the reservoir.

While in-depth science and modeling can aid in frac execution, in many cases it is simply the action of meeting new challenges with innovative approaches.

Increasing sand and water volumes per foot while decreasing the reliance on high‑viscosity crosslink to pump the designed sand concentrations, through a single-point completion methodology, improved contact with the reservoir while reducing post-frac costs.

The results achieved during this specific field development hinged on the willingness to challenge accepted practices and introduce measurable design changes. Dynamic engineering and working collectively with a service provider were also necessary elements that enabled the operator to grow production and increase reserves.

For Further Reading

SPE 209171 Parent-Child Well Relationships Across US Unconventional Basins: Learnings from a Data Analytics Study by J. Cozby, EOG Resources; M. Sharma, The University of Texas at Austin.

SPE 211899 Results from a Collaborative Parent/Child Industry Study: Permian Basin by M. McClure, ResFrac Corporation; M. Albrecht, SM Energy; C. Bernet, Ovintiv; C. Cipolla, Hess Corporation; et al.

Dustin Aro, P.E., is a vice president of operations for Precision Petroleum Solutions and has over 15 years of managerial and technical design/execution experience in high-volume US onshore drilling and completions operations management. His career includes US and international field/on-site and in-house roles with major and independent operators. He has also held executive level positions at multiple oil and gas engineering consulting firms that have provided strategic, technologically advanced oil and gas well completion design and execution in both unconventional and conventional reservoir settings. Aro is a licensed professional petroleum engineer in the state of Texas, having received his credentials under the Texas Board of Professional Engineers and Land Surveyors certification program. He holds BSc degrees in engineering and business administration from Michigan Technological University. He can be contacted at dustin.aro@ppsog.com.

Tim Hilton, P.E., is the vice president of operations at Steward Energy II, with over 15 years of leadership in the oil and gas industry. As an innovative engineer and operational executive, Hilton specializes in managing engineering and operational functions, including drilling, completions, production, and facilities with a proven track record of driving efficiency and growth. He has played key roles in building and scaling multiple private equity-backed companies, with successful exits demonstrating the ability to scale operations with a bottom-line focus. At Steward Energy II, he has overseen significant growth, driving production from 500 BOE/D in 2016 to over 29,000 BOE/D in 2023. He led the development of operational teams, budget management, and advanced engineering solutions, including a successful redesign of completions and artificial lift systems. Hilton’s efforts have resulted in increased productivity, reduced costs and extended equipment run times. A licensed professional engineer in Texas, he holds a BSc in mechanical engineering from Mississippi State University.

Connor Bradham is a senior operations engineer at Steward Energy II, with over 8 years of experience in oil and gas operations. His core competencies include production and operations optimization, reservoir engineering, and leading development programs, such as horizontal well projects across various fields and basins. With a strong background in drilling, completions, recompletions, and production management, Bradham excels at enhancing operational efficiencies and minimizing costs. His extensive experience working with multiple operators across different basins has been instrumental in driving strategic initiatives that improve well performance and profitability. He holds a BSc in petroleum engineering and minors in mathematics and mechanical engineering from the Texas Tech University.

Robert Gibbons leads sales and business development efforts for Stage Completions as an energy industry veteran with over 25 years of oilfield services experience in completions and interventions. He has held senior roles in both sales and operations and his expertise spans from startups to large enterprise business-to-business growth. With a proven track record of managing multimillion-dollar portfolios, particularly in the US land and Gulf of Mexico regions. Gibbons is known for building strong, collaborative relationships with clients. He holds a BSc in industrial technology from the University of Texas at Tyler and an MBA certificate from Tulane University. Gibbons can be contacted at robert.gibbons@stagecompletions.com.