Continuous downhole surveillance data is critical for informed reservoir management and field development decisions. Traditionally, operators rely on pressure data from drilling campaigns or rigless interventions such as static gradient surveys (SGS) or pressure buildups (PBU). However, these methods, with infrequent sampling and variable shut-in conditions, often yield noisy data that lead to ambiguous interpretations, suboptimal investments, and deferred production.

To overcome these limitations, four observation wells across two southern Iraq fields were retrofitted with real-time wireless downhole pressure and temperature gauges (PDGs). These gauges, capable of high-frequency data acquisition over extended periods, enabled continuous monitoring of reservoir response under stable conditions.

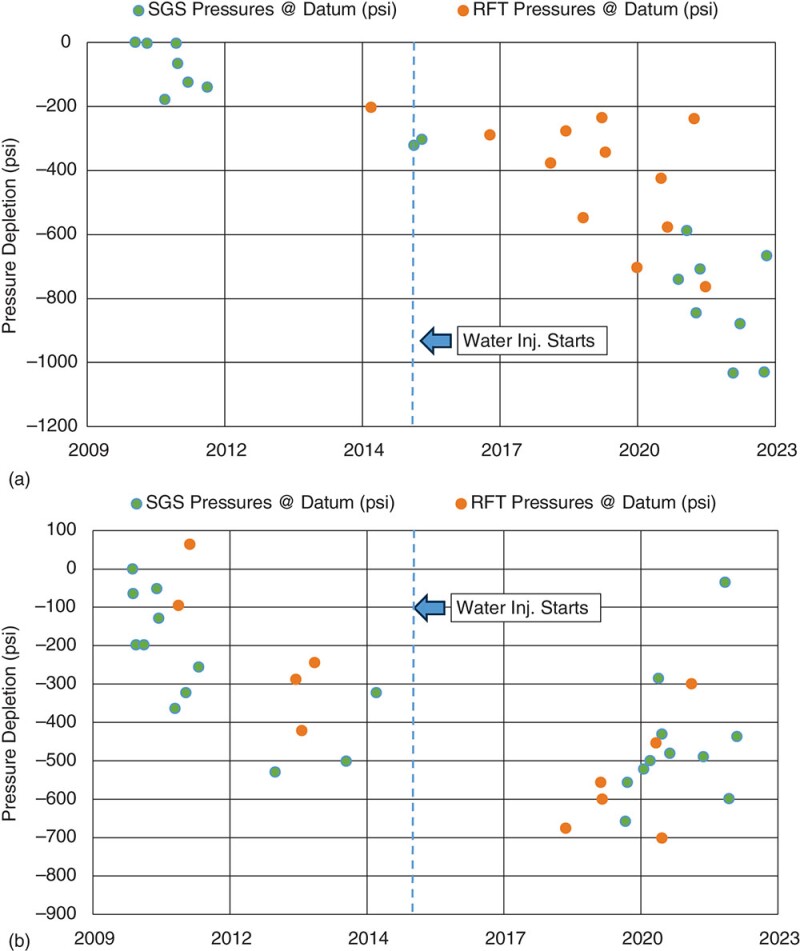

The two fields, having produced significant volumes under primary recovery, implemented secondary recovery via water injection schemes commissioned in 2016 and 2024. Evaluation of these schemes was essential before expanding infrastructure and committing further capital. Conventional SGS, repeat formation tester (RFT), and PBU data showed inconsistent pressure trends, providing insufficient support for key development decisions.

In contrast, analysis of the 14-month PDG dataset revealed clear and quantifiable reservoir repressurization, ranging from 9 to 160 psi per month, directly attributed to water injection. This continuous surveillance approach provided the high-confidence insights necessary for optimizing secondary recovery planning and justifying further investment.

Field Summary

Two oil fields in southern Iraq, discovered in 1949 and 1975, have collectively produced over 3.2 billion stock-tank barrels (STB) of oil through approximately 650 wells as of mid-2019. The first field is a north-northwest by south-southeast trending anticline with four structural domes, while the second comprises a mix of anticlinal and fault-controlled traps. The primary reservoirs are found in the Upper and Lower Cretaceous (first field) and from the Eocene to the Cretaceous intervals (second field).

Petrophysical analysis confirms that both fields contain limestone- and sandstone-dominated intervals with favorable porosity and permeability for hydrocarbon storage and production. Together, these fields represent approximately 15% of Iraq’s oil output and hold over 16 billion STB of proven reserves.

Operations were assumed by two international consortiums in 2009 and 2018, respectively, with plans to increase combined production to 1.65 million STB/D by 2028 through major infrastructure upgrades, including water injection and processing plants, pipeline networks, and new well developments.

After 5 years of production, reservoir pressure depletion became evident. In response, waterflooding projects were initiated. The first field’s water injection system was designed in 2013 and commissioned in 2016, injecting up to 300,000 BWPD through 2022. A second phase, targeting 850,000 BWPD, was proposed pending evaluation results. The second field launched a pilot injection program in July 2024, delivering 80,000 BWPD, with modular expansion plans contingent on demonstrated success.

Motivation and Well Selection

As shown in Figs. 1a and 1b, analysis of RFT, SGS, and PBU data from the first field indicated a 4–6 psi/month pressure decline until 2016. However, the impact of subsequent water injection was unclear due to data noise from formation heterogeneity, hydraulic barriers, infrequent sampling, and inconsistent measurement methods. These limitations led to high uncertainty in estimating repressurization, prompting the need for continuous downhole monitoring to support key final investment decisions.

Two observation wells A and B in the northern sector were selected for the first field’s repressurization assessment. In the second field, a continuous monitoring campaign was launched using observation wells C and D in a 1:2 injector-to-observer pattern to evaluate the effectiveness of early injections.

Wireless Technology Selection

For long-term reservoir monitoring during both production and shut-in phases, the SonicGauge Wireless Monitoring System, a commercial real-time telemetry PDG designed and developed by Acoustic Data, was selected for its operational simplicity, reliability, and cost-effectiveness. The wireless PDG transmits data acoustically through the production tubing to surface in real time, enabling continuous monitoring without the need for wellhead modifications.

The system is compact, retrofittable via slickline, and deployed using a nonexplosive, electro-mechanical setting tool. Its 1.31-in. outside diameter high-expansion gauge hanger allows flexible installation at any depth without requiring a pre-installed nipple or profile, making it compatible with most well designs.

Advantages include:

- Fully wireless installation with no rig or tubing retrieval required.

- Quick deployment and commissioning of 2 to 4 days.

- Long service life of up to 8 years, depending on data frequency and bottomhole temperature.

- High-accuracy Quartzdyne or Keller sensors for pressure and temperature measurement.

- Cost-effective redress and redeployment via slickline upon battery depletion.

Given that traditional workovers—often exceeding $2 million to $3 million for PDG installation and rig mobilization—would surpass budget constraints, the real-time wireless PDG offered a practical alternative. It met all technical and commercial requirements for enabling continuous downhole surveillance in a nonintrusive manner.

Instrumentation Design and Installation

An in-house acoustic attenuation model was developed for each well to estimate signal loss and optimize the number and placement of acoustic repeaters. Key design inputs included well completion diagrams and deviation surveys, which were critical to ensuring reliable data transmission from the downhole real-time wireless PDG sensors to the surface-mounted sonic data logger (SDL) located at the Christmas tree. The SDL transmits real-time pressure and temperature data to the operator's office server, enabling continuous monitoring.

In the first field, well A was instrumented with real-time wireless PDGs installed at a depth of 2,175 m, while well B had them installed at 2,400 m. The design was completed with sufficient repeaters to ensure that PDG data packets were transmitted all the way to the surface. The deployment in well B was completed over 2 days in July 2022. The tools were later retrieved in October 2022 and reinstalled in well A during a subsequent 2-day operation.

In the second field, wells C and D were equipped with three real-time wireless PDGs, each positioned at depths of 2,380 m, 2,083 m, and 1,548 m, and 2,380, 2,227, and 1,882 m, respectively. Installations in both wells were executed in November 2024, each requiring approximately 3 to 5 days to complete. The multisensor configuration in wells C and D offers the added benefit of capturing pressure gradients, which can be leveraged for monitoring fluid contact movements or early detection of water breakthrough.

Instrumentation Performance and Data Analysis

First Field Results. Real-time wireless PDG in wells A and B were configured to transmit one pressure and temperature data every 2 hours. A real-time wireless PDG data logger was installed on the existing concrete pad (Fig. 2 above).

Monitoring began immediately in well B and continued for 99 days, followed by well A, for 288 days until August 2023. Both systems operated autonomously, powered by solar panels and used mobile networks to transmit data to a secure cloud server.

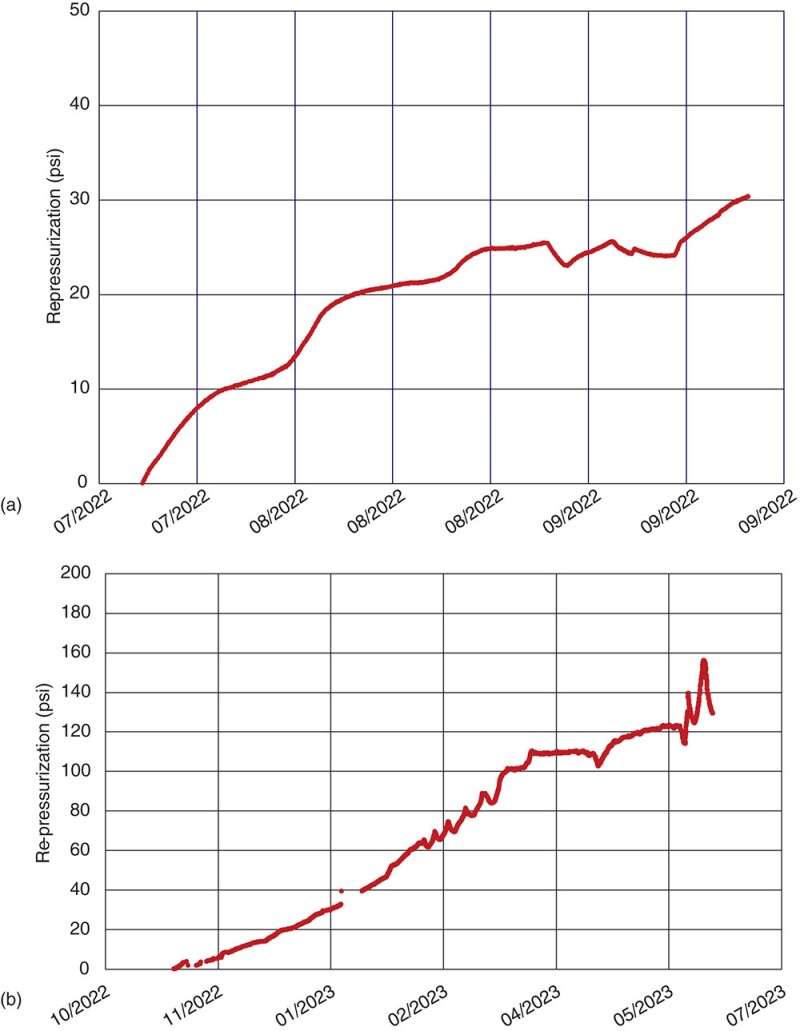

Figs. 3a and 3b show a clear repressurization trend of about 20 psi/month, validating the effectiveness of water injection. These results supported a major investment decision to upgrade water- handling capacity to 850,000 BWPD, enabling oil production of up to 700,000 B/D.

Second Field Results. Instrumentation in wells C and D was set to transmit data every 4 hours, starting 19 days post-deployment. The data loggers were powered on-site, with data transmitted via MODBUS.

The instrumentation deployed in the second field provided continuous data to confirm repressurization rates of 9 psi/month in well C and 160 psi/month in well D. Although both observation wells monitor waterflooding impact from a single injector well, the resulting large repressurization difference highlights substantial reservoir heterogeneity and varying connectivity within the same hydraulic compartment.

Conclusions

This study focused on two mature oil fields in southern Iraq experiencing depletion, which prompted the design and commissioning of water injection schemes. Candidate selection, system design, and deployment of real-time wireless PDGs were implemented to monitor reservoir repressurization and assess injection effectiveness.

In the first field, more than 365 days of continuous pressure data confirmed successful repressurization in the northern area, with an average increase of about 20 psi/month. In the second field, 70 days of monitoring showed contrasting repressurization rates of 9 and 160 psi/month, indicating significant reservoir heterogeneity.

These results validated the effectiveness of waterflooding, supported critical field development decisions, and provided the confidence to proceed with investments in facility upgrades and new wells to enhance production and recovery.

Mark Tolley, CEO and cofounder of Acoustic Data, is an Australian petroleum engineer with over 40 years of global experience in oil and gas exploration and production. He envisioned a sonic-based wireless gauge system in the early 1990s and has led mechanical engineering for Acoustic Data's technologies. He is experienced in financial markets, investor relations, general management, project and production operations management, production technology, reservoir engineering, and wellsite operations. He also has experience in the Commonwealth of Independent States and is fluent in Russian. He can be reached at mark@acousticdata.com.

Jesse Tolley, chief commercial officer and cofounder of Acoustic Data, is a New Zealand citizen with 20 years of global experience in oilfield services and investment banking. Since cofounding Acoustic Data in 2012, he has led the product management for the company’s sonic technologies, including the development roadmap and the go-to-market strategies. Additionally, he has managed sales and marketing, channel partners and technology integration, and investor relations and capital raising. He holds a bachelor of commerce in finance from the University of Canterbury. He has experience in Asia Pacific, Middle East and North Africa, and Latin America regions and is fluent in Spanish. He can be reached at jesse@acousticdata.com.

Matthew Norgate, chief operations officer of Acoustic Data, is a British citizen with over 25 years of global experience in the oil and gas industry, primarily focused on downhole data acquisition and sensors. Prior to joining Acoustic Data, he worked for Baker Hughes GE, where he held several senior operational, commercial, and product management roles in their wireline businesses. He holds a degree in mechanical engineering with a modern language focus (French) from the University of Sheffield and an MBA from Imperial College. He can be reached at matthew@acousticdata.com.

Mariano Fernandez, senior reservoir engineer at Acoustic Data, specializes in data interpretation and the application of wireless downhole monitoring technologies. He began his career with Shell in Venezuela as a production technologist, later transitioning into development planning and reservoir engineering roles with Lasmo, which was subsequently acquired by Eni. Over the course of his career, he has contributed to a range of international projects, including reserves assessment and reporting for Carigali-Hess in Malaysia, as well as consulting assignments in offshore Morocco and onshore Algeria. He holds a DPhil in engineering sciences from the University of Oxford and a BSc in electronic engineering from Universidad Simon Bolivar in Caracas, Venezuela. He can be reached at mariano@acousticdata.com.