Decommissioning is approaching a new frontier as deepwater structures are slated for removal in the Gulf of Mexico (GOM) and the Pacific Outer Continental Shelf (POCS).

Robert Byrd, vice president of TSB Offshore, provided an overview of US offshore decommissioning activities during a luncheon hosted by the SPE Gulf Coast Section’s Projects, Facilities, and Construction study group in February.

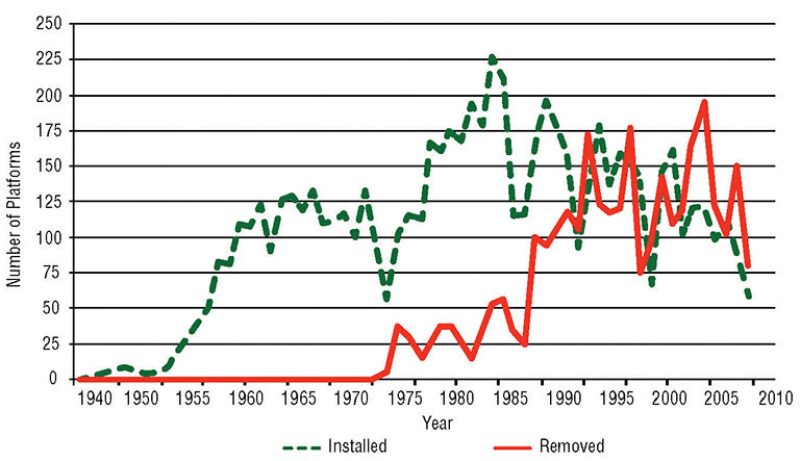

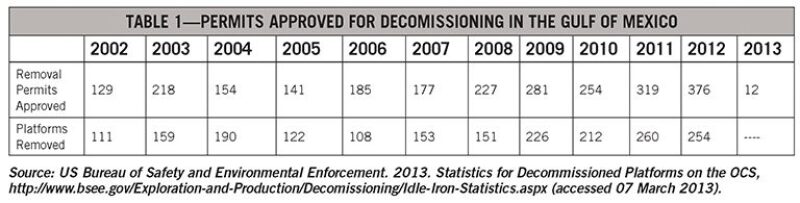

He pointed out that although the industry has a long history in decommissioning, it has developed the engineering, skills, and equipment needed for shallow water. The number of decommissioned platforms has outpaced the number of installations in the GOM since the early 1990s (Fig. 1). The US Bureau of Safety and Environmental Enforcement’s (BSEE) Idle Iron regulations will continue to drive decommissioning activities in the GOM as platforms meet the criteria of being toppled or not having been used in the past 5 years for operations associated with exploration, development, or production of oil and/or gas. BSEE records indicate that 813 platforms fit the criteria of Idle Iron or are nonproducing and that 359 platforms are scheduled for removal this year (Table 1).

Big Structures, Big Challenges

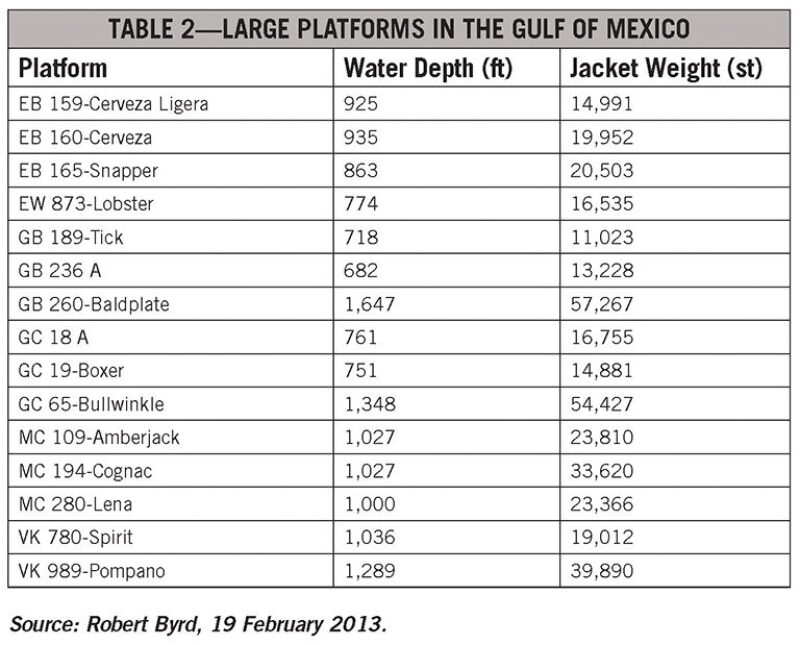

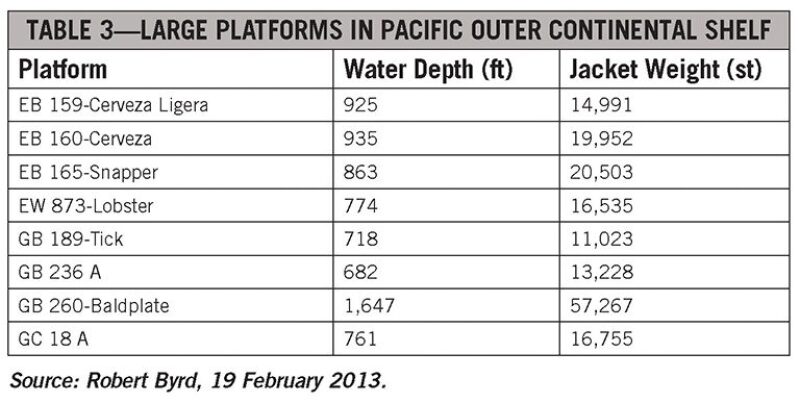

The decommissioning of larger deepwater structures will present challenges. Tables 2 and 3 list the inventories of GOM and POCS deepwater platforms and show the water depths and jacket weights of the structures.

While the general approach to decommissioning will remain similar—site clearance, planning, inspections, permitting, substructure and topsides removal and disposal, conductor removal, pipeline abandonment, platform preparation, and well plugging and abandonment—removal of deepwater structures will require innovative engineering.

Simply reversing the steps used in the installation of deepwater structures may seem like a straightforward approach, but it quickly runs into obstacles. Byrd said, “Truss spars will be interesting to decommission. Most of the ballast slurry used in installation is now solidified. Getting spars into a horizontal position will be challenging.”

Byrd said that some of the largest offshore facilities—with jackets weighing more than 10,000 standard tons and/or in water depth of more than 1,000 ft—are now in prefeed status for decommissioning, and he predicts that at least one of them will be removed in the next 3 to 5 years.

Three deepwater structures being considered for removal are Exxon’s Lena guyed tower and Shell’s Cognac fixed steel platform in the GOM Mississippi Canyon, and an unnamed POCS platform with a jacket weighing more than 10,000 tons installed at water depth greater than 400 ft.

In 1983, the Lena guyed tower (Fig. 2) was installed in water depth of 1,000 ft and required special equipment and procedures to handle and place 20 guy lines. Each guy line is an assembly comprising a 6-ft diameter anchor pile, three segments of large-diameter structural strand, and a 200-ton articulated clump weight. Installation of the 58 conductor strings required the handling, aligning, and welding of more than 800 pieces of 26- and 22-in. conductor pipe (Smetak et al. 1984).

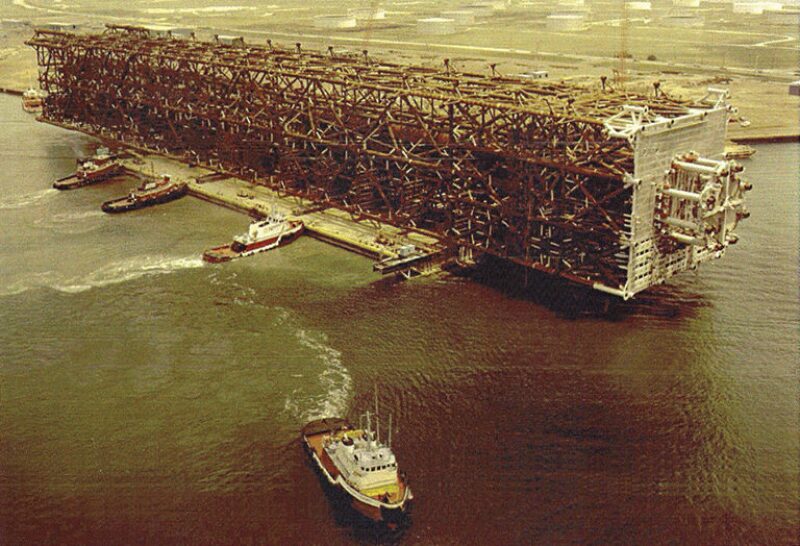

The Cognac platform began production in 1979. Its tubular steel frame was built in three parts and floated by barge to the installation site where the parts were joined subsea, using divers to 1,000-ft depths. Weighing 14,000 tons, the 178-ft high base section was lowered 1,000 ft to the seafloor and anchored with 24 piles, each measuring 7 ft in diameter. Each 465-ton pile sank 150 ft into the bottom under its own weight and then was driven another 300 ft by an underwater hydraulic pile driver. The 300-ft middle section and 650-ft top section were attached along cone-shaped guides, and 1,000-ft leg pins were inserted through the structure’s 10 legs, permanently bonding the sections (Sterling and Warrington 1979).

Jackets, Conductors Drive Up Costs

Byrd said that deepwater structures, such as the Cognac, were presumed to be left in place permanently. Removal issues include the handling and disposal of asbestos and lead in the platforms. Environmental and safety regulations in the 1970s did not define these materials as hazardous substances.

The jackets’ heavy weights and the pulling of conductor lines will be significant cost drivers in the decommissioning of large structures. Byrd said, “No jackets have been removed from water depths greater than 400 ft. In completing cost estimations for these large structures, pencils are going to get a whole lot sharper.”

For example, Lena has 58 conductors that have to be pulled. As the conductors are pulled, the structural load will increase. Engineering solutions are needed to handle the high structural loads during the platform’s disassembly. Alternatives are also needed for removing the piles. Byrd said, “The industry has no experience in jetting out piles in depths greater than 400 ft.”

In the POCS, approaches being considered for the decommissioning of deepwater structures include the abrasive severing of a structure’s piles 15 ft below the mudline for jacket and pile removal. The structure could be removed in one piece or cut into sections small enough (40% to 50% of full crane capacity) for its safe and efficient removal by a heavy-lift crane. Transport to shore by cargo barge for disposal may be an option. However, the availability of onshore facilities willing to dispose of the materials is a significant limitation. Reefing options are unlikely because of POCS regulations.

As in the creation of the deepwater structures, innovation in facilities engineering and new applications of existing knowledge and expertise will likely lead to remarkable results in their decommissioning.

For Further Reading

OTC 3494 Design of the Cognac Platform for 1025 Feet Water Depth, Gulf of Mexico by G.H. Sterling, B.E. Cox, and R.M. Warrington, Shell Oil Co.

OTC 4683 Jacket, Deck, and Pipeline Installation—Lena Guyed Tower by E.C. Smetak, J. Lombardi, and H.J. Roussel, Exxon Co., and T.C. Wozniak, Brown & Root.