To commercialize some of the world’s most challenging deepwater fields, offshore engineering companies are developing a new class of drilling and production platform known as the dry tree semisubmersible (DTS). The challenge involves taking existing technologies and lessons learned from previous floater designs to create an alternative platform for waters too deep to cost-justify the use of tension-leg platforms (TLPs) and fields too large for spar platforms.

Dry trees, also known as Christmas trees, are wellhead devices installed during the completion stage of a well’s life and give the operator control over production. Used on onshore wells, dry trees have been used extensively on shallow water fixed platforms, TLPs, and spars, but never on a deepwater semisubmersible because that platform’s motions are too extreme to support a dry tree system.

As the DTS concept awaits introduction into the deepwater market, multiple designs are under evaluation by major offshore oil companies and the Norwegian classification society Det Norske Veritas (DNV).

The chief advantages of using a DTS are that operators can drill, complete, and carry out intervention operations on multiple wells from the same platform in depths below 6,000 ft. This saves the operator significant resources that otherwise would be spent over the life of the field on contracting mobile offshore drilling units or purpose-built, well-intervention semisubmersibles.

Going Deeper With a DTS

A TLP typically uses four columns to support a large topside facility and is secured to the seafloor with mooring lines that allow the floating platform to move from side to side, but not up and down. Operating at a water depth of 4,674 ft, ConocoPhillips’ Magnolia TLP in the US Gulf of Mexico (GOM) is the deepest structure of its kind in the world. Next year, Chevron hopes to begin first production from its Big Foot TLP, also to be located in the GOM, at a depth of approximately 5,200 ft. Beyond 6,000 ft, TLPs become impractical because of the amount of steel needed for the tendons that moor the platform to the ocean bottom.

A spar platform supports drilling, production, and storage operations and achieves stability from the deep draft of the vertical column on top of which the topside sits. Spars have virtually no water depth limit and are designed specifically as a dry tree unit. However, their size is limited by their cylindrical hulls, which constrain the available deck space, thereby pushing designers to stack the decks vertically. When scaled up to increase the deck area comparable to that of a TLP and to add the payload capacity required for a deepwater drilling rig, the hull of a spar introduces tremendous challenges for transportation and installation. Measuring 555 ft in length, Shell’s Perdido spar is the deepest in the world, operating at a depth of 7,844 ft in the GOM. Because the deep draft of spars exceeds the water depth near a fabrication yard and create too much drag to wet tow vertically, they must be transported on their side, then upended on location, and have the topside installed onto the hull at sea.

Operators are increasingly seeking to avoid this type of offshore integration because of the risk and cost involved, especially for large topside decks. The safer and more cost-effective option that the DTS allows for is quayside integration of the hull and topside, where sea motions are minimal and the need for a heavy lift vessel is eliminated.

A conventional semisubmersible platform offers the optimum amount of deck space for safer operations and payload flexibility that a spar cannot, but it has too much vertical motion for a dry tree to operate safely. Several semisubmersibles operate in depths exceeding 6,000 ft; however, all of them use subsea trees. Unlike subsea trees that are installed at the seabed and deliver hydrocarbons to a surface platform through a flexible production riser or a metallic riser such as a steel catenary riser (SCR), a dry tree uses a rigid riser system known as a top tensioned riser (TTR) that is locked onto the subsea wellhead at the seafloor and to the dry tree at the platform deck, thereby making it very sensitive to movement.

Another difference is that when using a DTS, the rigid risers dictate that the wells be drilled directly beneath the platform in comparison to semisubmersibles, which use subsea trees that can span large distances between each other. On a DTS, each well has its own riser, whereas in a subsea tree scenario, depending on the rate of production, multiple wells can tie into a single riser.

Short Stroke vs. Long Stroke

Although the DTS hull is designed to reduce motion caused by ocean forces, it is the motions that move the platform up and down that are of the highest concern. To compensate for excessive vertical motion current, DTS concepts are relying on proven riser tensioner technology. Riser tensioners have been used on TLPs and spars for nearly 3 decades and are connected to the uppermost segment of a TTR at the platform. Like the shocks on a car, riser tensioners absorb the vertical heave motion caused by ocean waves, allowing the riser to move up and down in a controlled manner without over or under tensioning the riser.

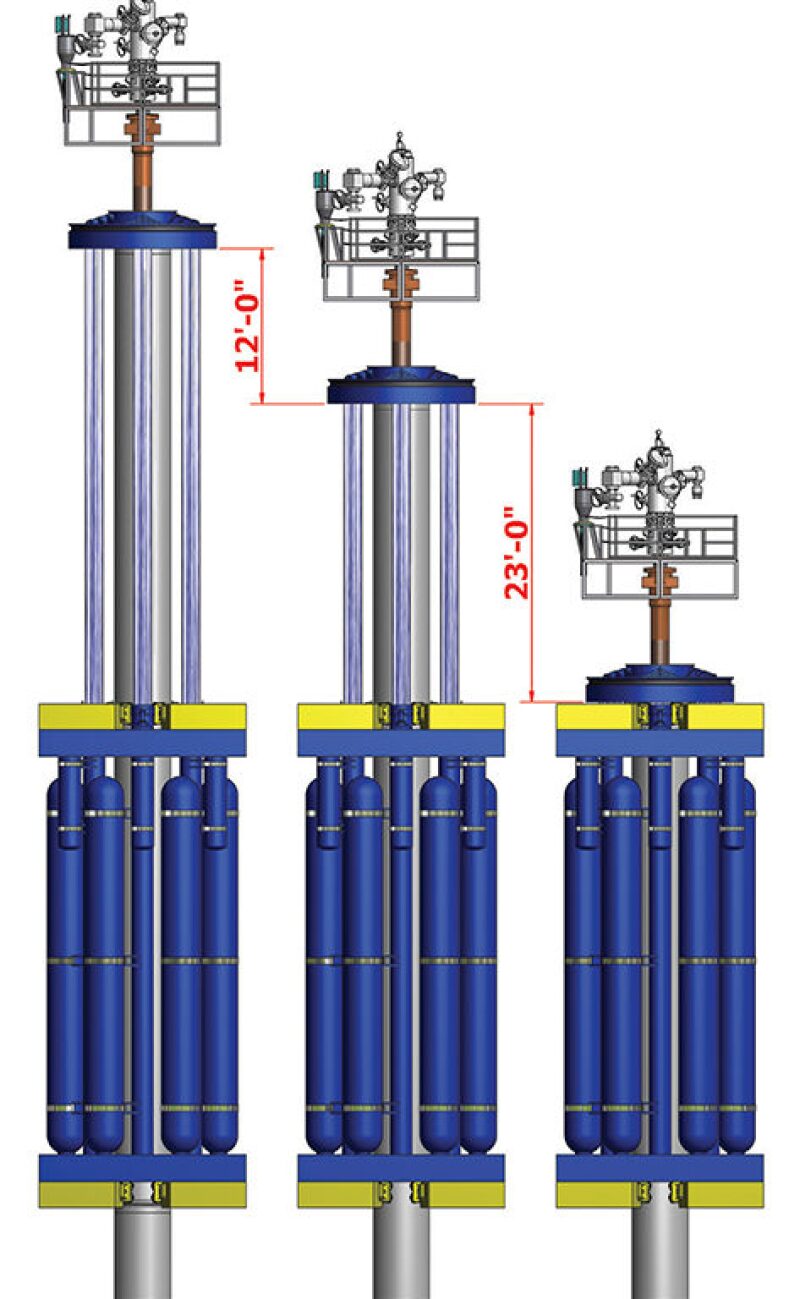

A key difference in some of the DTS concepts is the stroke length that the tensioners need to compensate riser motions vertically. In modified DTS hull designs with deep drafts or additional dampening devices, conventional short-stroke riser tensioners are used to compensate for the heave. In conventional hull designs, longer stroke riser tensioners are needed to compensate for a greater heave movement. The required maximum safe range of the tensioner stroke is largely dependent on field conditions and can be as short as 25 ft in severe environments. To be qualified for global field development applications, each DTS concept must be designed to survive a 1,000-year hurricane in the GOM. In some designs, the riser tensioners must have a stroke length of up to 45 ft.

A driver for the modified hull DTS with a deep draft is the preference that operators have shown for a short-stroke tensioner length within the range of 30 ft to 35 ft (Fig. 1). However, as the length of the columns grows to mitigate heave, so does the cost of the hull. Another construction issue that will need to be addressed is whether to dredge quayside at the shipyard to accommodate a substantially deeper draft platform or complete the hull and topside integration offshore.

In addition to supporting TTRs, the DTS concept is being evaluated for its applications in subsea tiebacks of satellite wells using flexible or steel catenary risers (SCRs). Connected to subsea pipelines and subsea trees, SCRs are flexible metallic risers that bend in a catenary shape as they deliver oil and gas to a production platform. Over time SCRs become susceptible to fatigue as the host platform sways, thereby weakening the steel at the point closest to the seafloor known as the touchdown zone. With the improved motions of a DTS hull, SCR performance could be enhanced, thus extending its service life.

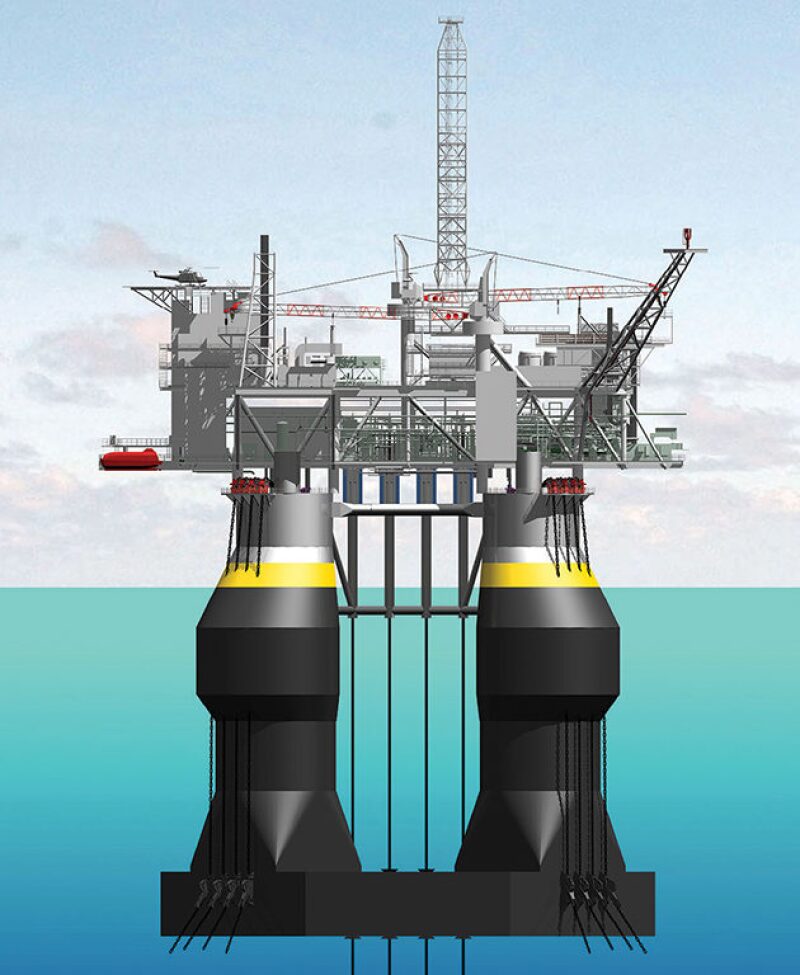

Octabuoy: The First DTS

Moss Maritime says its Octabuoy (Fig. 2) is the world’s first DTS concept to be purchased by an oil company and has gained certification from the American Bureau of Shipping and DNV, and validation by a number of other operators as a dry tree unit. In 2008, Moss Maritime sold the license to build the Octabuoy to ATP Oil and Gas, which has completed the construction of the hull in China but has yet to commission the unit for service. The ATP Octabuoy was designed to produce up to 175,000 B/D of oil in the North Sea using subsea trees and for the deeper waters of the GOM using dry trees.

The Octabuoy’s four conical columns are connected to the octagon-shaped pontoon for which the platform’s name is derived from. The columns, which can be used for oil storage, have a profile with a variable water line and dimensions that minimize platform motions. This grants the platform superior motion characteristics compared with a spar and the transport and installation simplicity of a semisubmersible.

“We’ve placed the columns on the outside of the pontoon ring to give us greater stability,” said Roberto Noce, general manager of Moss Maritime. “Now you’re able to integrate a deck with a footprint as large as needed, and once you put in a bigger deck, you can spread your equipment out more efficiently and safely, because you can keep hazardous areas away from the living quarters.”

The conical shape of the columns does not present fabricators with any significant challenges, Noce said, proving that the design adheres to conventional construction methods and semisubmersible technology. Moss Maritime has completed multiple field-specific testing and engineering studies on the use of the Octabuoy for Chevron, Petrobras, Shell, and Statoil.

Paired Column Semisubmersible

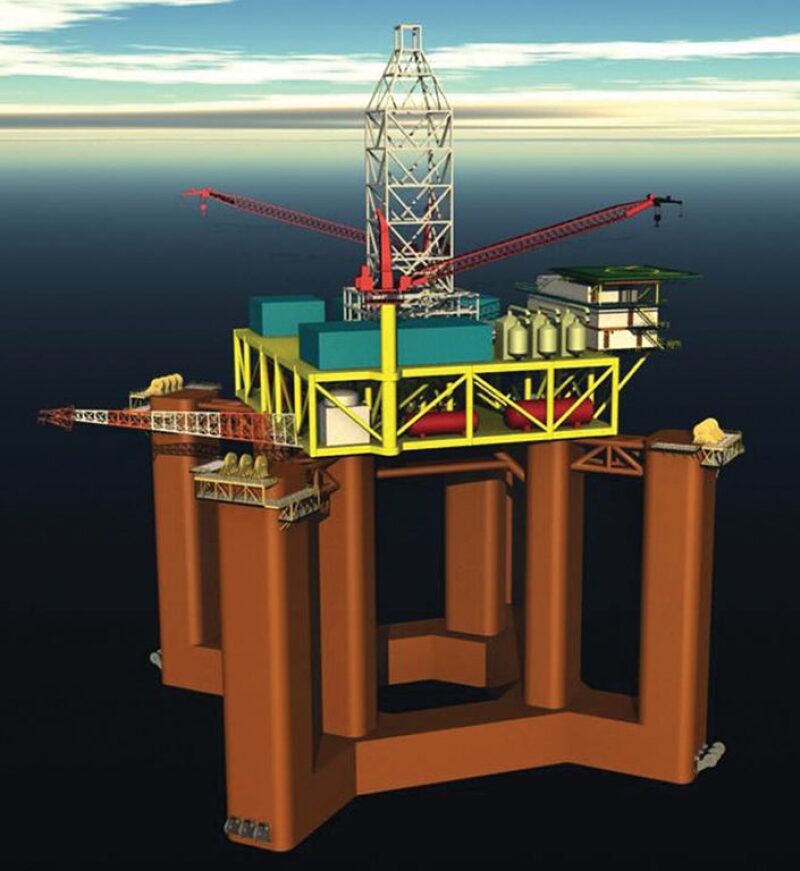

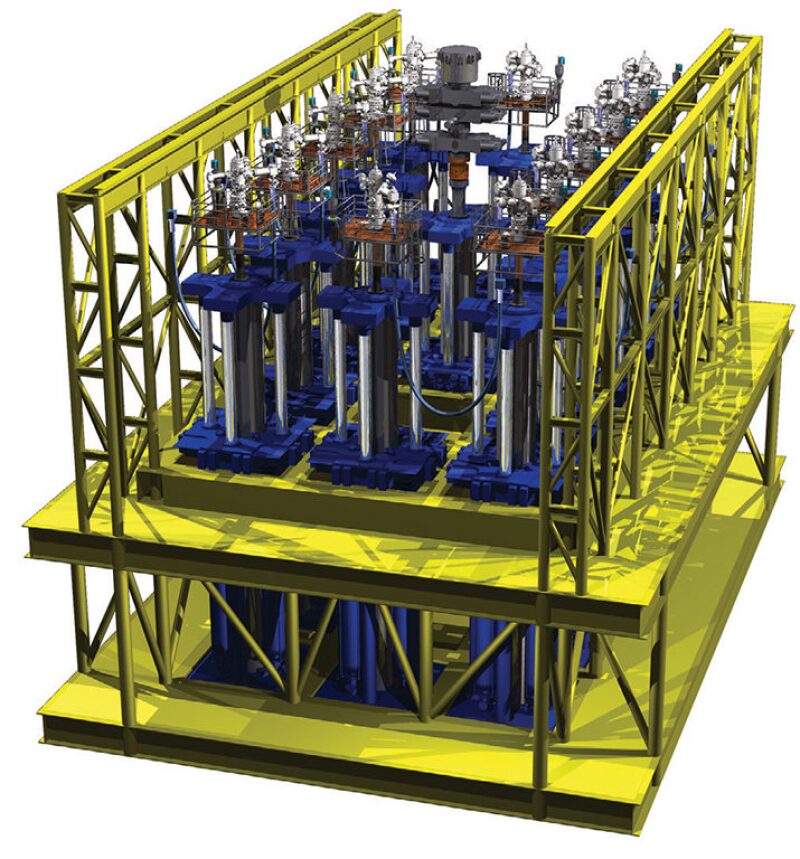

Houston Offshore Engineering’s paired column semisubmersible (PCS) (Fig. 3) uses four large outer columns and four smaller inner columns to achieve the stability required in using existing tensioner technology. The inner columns support the topside decks and the outer columns provide motion stability.

By increasing the size of the columns, or by changing the distance between the outer and inner columns, the PCS can accommodate varying deck payloads. Pairing the columns in this configuration cancels out surge and sway motions. The paired column concept has shown that it can reduce what are known as vortex-induced motions (VIMs) caused by the loop current in the GOM. VIMs are a major contributor to the fatigue of SCRs and eliminating this type of motion would increase their service life. In June, the PCS underwent tank testing to evaluate its VIM performance and the results were better than expected.

“The VIM motion is actually significantly less than the single column (semisubmersibles) which gives us a big advantage in regards to mooring line fatigue,” said Jun Zou, manager of naval architecture at Houston Offshore Engineering,

He added that his company’s design is compatible with a short-stroke tensioner system capable of a 28-ft range for use in the most severe GOM environments. The PCS is designed to process 100,000 B/D of oil and the company has completed a study to increase the design capacity to 150,000 B/D.

Conventional Semisubmersible Solutions

Another approach is to use a conventional deep-draft semisubmersible platform and incorporate long-stroke riser tensioners to compensate for the greater heave motion. Kvaerner Field Development and Aker Solutions are both developing DTS concepts that feature a ring pontoon with four corner columns supporting the topside.

The Kvaerner DTS (Fig. 4) is based on prior in-house semisubmersible designs and uses a long-stroke tensioner with a range of 35 ft. The hull is deeper than a conventional semisubmersible but within the limits that allow for quayside integration and commissioning.

“The hull itself looks a lot like a conventional semisubmersible except the draft of the underwater portion, the column, is deeper, because of the riser performance requirement,” said Jack Zeng, director of engineering and technology for floaters at Kvaerner.

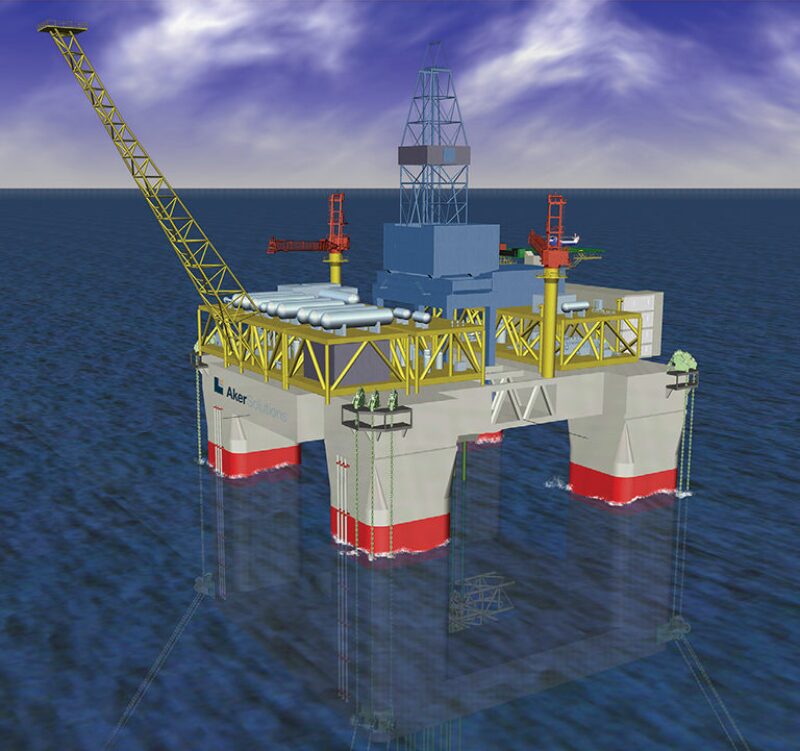

The Aker DTS (Fig. 5) concept is based on the company’s existing semisubmersible designs that have been used to build offshore units already in service. The Aker design has been modified only slightly in regards to the configuration of the drilling rig and well bay to accommodate for tensioner stroke and deeper columns.

The Aker DTS will use the same riser tensioner technology used on the company’s drilling rigs, but the stroke length will increase by a few feet from the current maximum range. For use in the GOM, the Aker DTS will have a riser stroke range of 35 ft to 45 ft as dictated by storm survival requirements. Aker is studying the use of smaller stroke riser tensioner in areas where stroke requirements are less extreme because of calmer seas, such as off west Africa and in southeast Asia.

“This is being looked at to use around the world so that we find fields that are really perfect for a DTS with the right depth and right field conditions,” said Rolf Eide, manager of hull and marine engineering at Aker. The Aker DTS is in the final stages of qualification with DNV and Chevron.

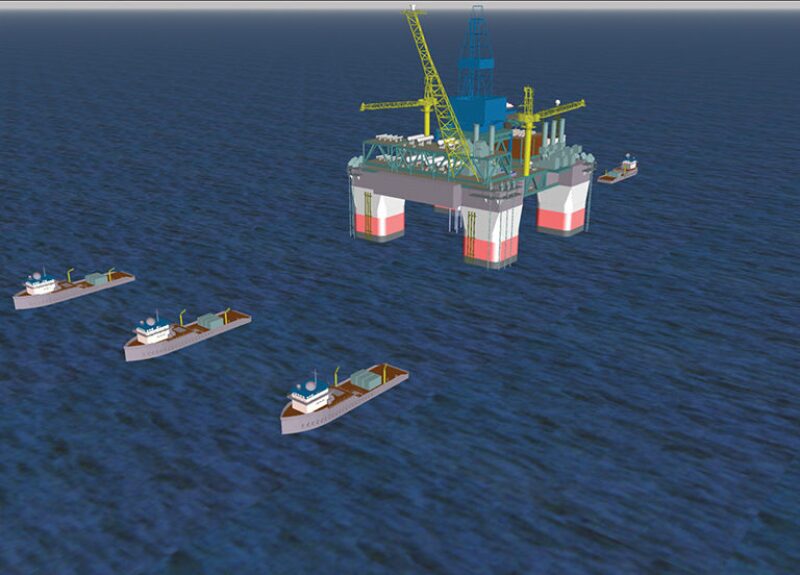

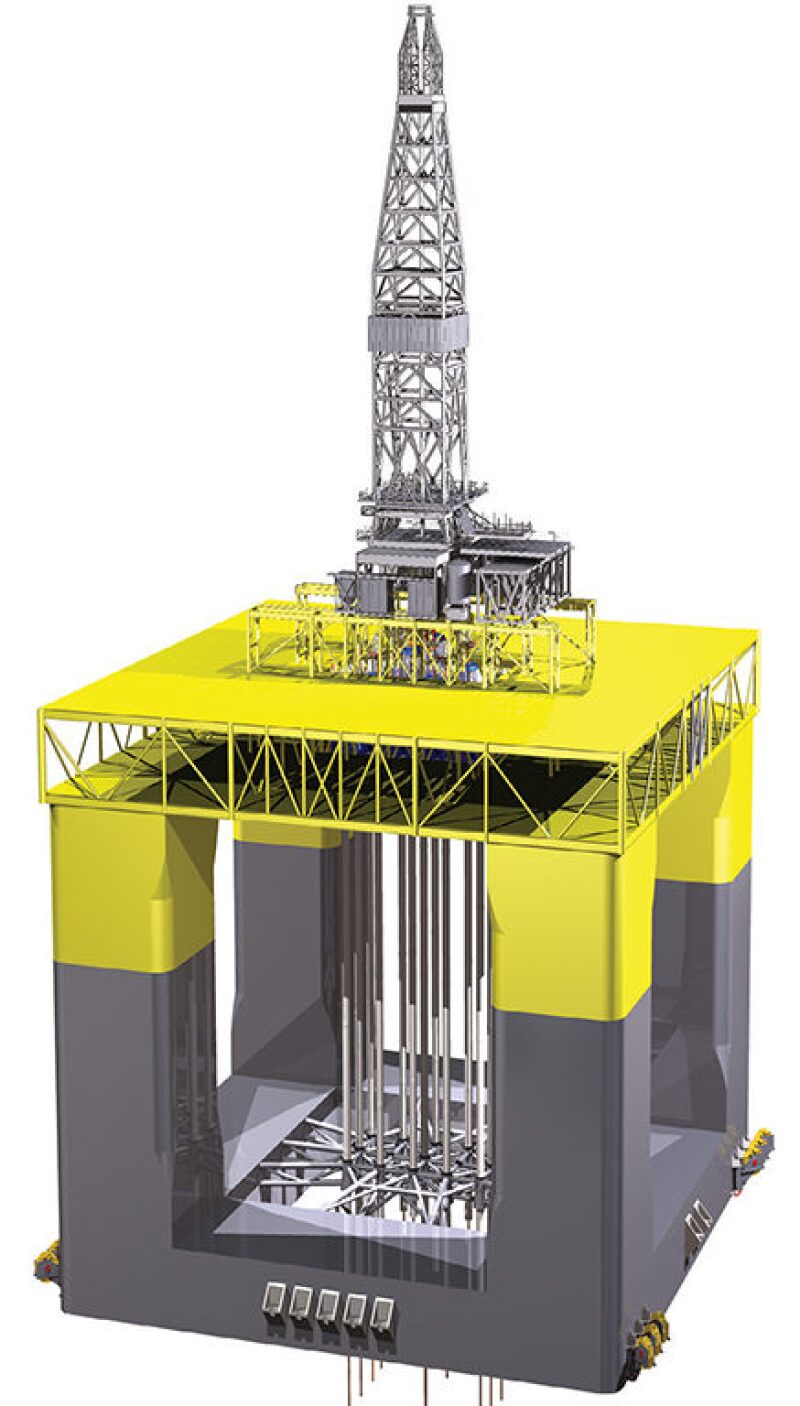

SBM Offshore is following the same path as Kvaerner and Aker in developing its own version of a DTS (Fig. 6 and Fig. 7) by using the design of two semisubmersibles operating in the GOM. Compared with its two other deep draft semisubmersibles, SBM’s DTS concept would be more than twice the weight with 50% more draft.

“We’ve extended the draft another 50 ft in our design beyond what we did for the Independence Hub and Thunderhawk,” Randy Jordan, vice president of floating production systems at SBM Offshore, said.

Independence Hub is the deepest operating semisubmersible in the world at approximately 8,100 ft in water depth and it processes 1 Bcf/D of natural gas. The SBM Offshore DTS has a 150-ft draft and is designed for depths up to 8,000 ft. Based on results from a wave basin model test completed in April, Jordan said its DTS design is ready to be used for field development in west Africa, Brazil, and southeast Asia. The company will reveal the results of its recent testing at OTC Brasil in October.

Challenges Remain for Adoption

The riser tensioner technology that the DTS concept relies upon has been proved on drilling rigs, but not on floating production platforms. Because drilling rigs are required to enter dry dock for inspection every 5 years and floating production facilities are designed to operate at sea for decades without coming to port, operators are seeking a high level of certainty on the long-term integrity of the riser tensioner systems.

Other safety issues that are under review include outlining the contingencies for a riser tensioner or supporting system failure and the safest way to arrange the well bays so as to protect the integrity of the riser tensioner system.

Consideration must also be taken in the designs regarding how to safely conduct drilling and production operations simultaneously in a well bay crowded with multiple riser tensioners. And because no DTS has been field proven in deep water, the concept’s cost-effectiveness has yet to be determined.

For Further Reading:

OTC 23912 A Project Oriented and Technology Robust Dry Tree Semi Concept by Jack Zeng, Kvaerner, et al.

OTC 23919 Dry Tree Semi Technology Readiness—Perspectives of Operator and Classification Society by Jenny Yan Lu and Ming-Yao Lee, DNV/Chevron, et al.

OTC 23926 An Evaluation of Strength, Fatigue, and Operational Performance of Dry Tree Semisubmersible Riser Tensioning Equipmentby Jun Zou, Houston Offshore Engineering, et al.

OTC 23958 A Robust and Flexible Dry Tree Semisubmersible Drilling and Production Platform by Roberto Noce, Moss Maritime, et al.

OTC 24148 Dry Tree Semisubmersibles for Gulf of Mexico by Steve Leverette, SBM Offshore, et al.