They were told it wouldn’t work.

But in a new study, experts at Equinor and Applied Petroleum Technology (APT) suggest they are on the brink of using contaminated drill cuttings to predict critical reservoir fluid properties.

The two Norwegian firms believe their project will soon make it possible to treat cuttings, collected from each well, as if they were pressure/volume/temperature (PVT) samples, which are collected from a significantly smaller share of wells due to the risks and high cost of doing so.

Since its inception in 1972, Equinor has drilled over 5,000 offshore wells, from which just over 2,000 PVT samples have been gathered.

Given that only two or three good samples are taken from most wells—almost always exploration wells—a significant data gap exists for the remainder, most of which are the subsequent development wells. And each year, Equinor drills around 20 to 25 new wells, mostly near existing platforms.

If oil and gas firms could obtain PVT-like results from cuttings alone, they would presumably gain more precise guidance on where to place new wells along with insights on facility/topside design, reservoir management, and eventually on the plugging and abandonment phase.

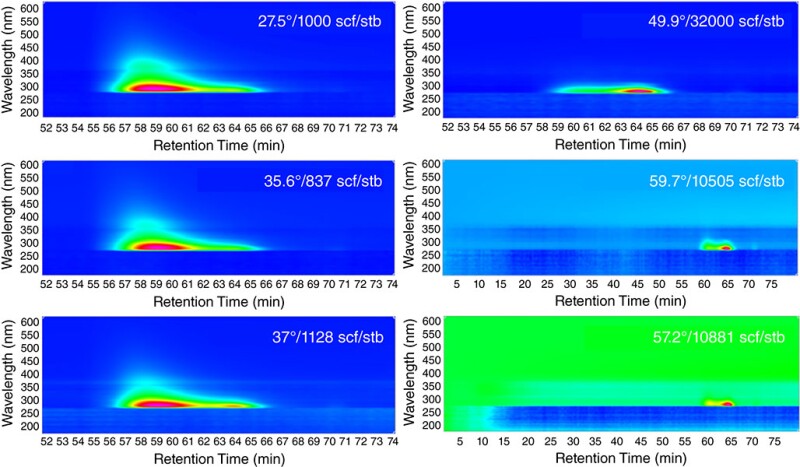

The big obstacle Equinor and APT are trying to surmount centers on how rock cuttings are soaked in oil-based muds (OBMs) as they circulate up the wellbore before being collected from a shale shaker. The oil ends up masking the reservoir’s hydrocarbons, rendering traditional geochemistry methods ineffective.

What Equinor has shown in its study is that problem can be circumvented to obtain reliable estimates of API gravity and viscosity, two defining aspects of reservoir fluid quality and flow potential. Several more outputs are in the works.

Tao Yang, an industry-recognized reservoir expert and chief professional at Equinor, said when he spoke with geochemists in the company about the project nearly 2 years ago, they were decidedly dubious.

“They gave us a warning at the beginning and said that this was a very difficult area, that the cuttings were too dirty, and that we probably wouldn’t get anything out of them,” he said.

But what few in the upstream industry knew at the time is that there existed a technology that can overcome the contamination issue—and it has been around for decades.