A foamed cement solution was designed and implemented to cement shallow intermediate casing strings in a heavy oil play in northeast Alberta after conventional area-specific cementing solutions could not prevent surface casing vent flows. Foamed cement was pursued as a better alternative technical solution and ultimately led to its successful placement in the field. Significant technical and operational hurdles were overcome to confirm proper well control and ensure that the energized cement could be pumped safely and effectively.

Introduction

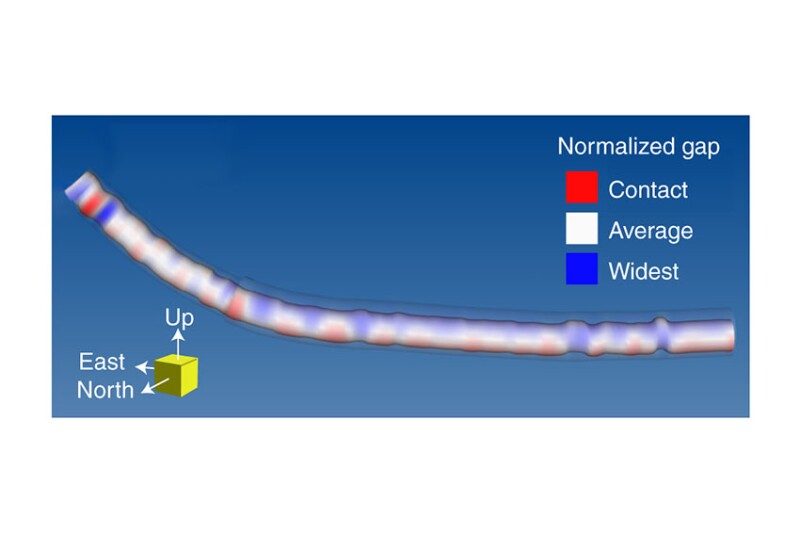

MacKay River is Alberta’s shallowest steam-assisted gravity drainage (SAGD) project, with wells typically ranging between 100 m and 150 m true vertical depth (TVD). Wells have been drilled recently at MacKay River with a horizontal length approaching 1000 m and total length exceeding 1500 m measured depth (MD). Wells at MacKay River are drilled using a slant rig because of the extremely shallow depth of the reservoir. The wells feature a three-string casing design with a shallow surface casing, an intermediate casing that runs from surface to the target formation and is landed at 90° inclination, and a horizontal production (or injection) liner hung off the intermediate casing.