Numerous articles and technical papers have shown that perforating and fracture stimulating previously undrained rock in wide-cluster-spaced legacy organic shale wellbores can result in superior economics to new wells in many areas. With advances in mechanical isolation operators can seal off the narrow existing drainage intervals in legacy wells to enable stimulations to focus on “new rock.”

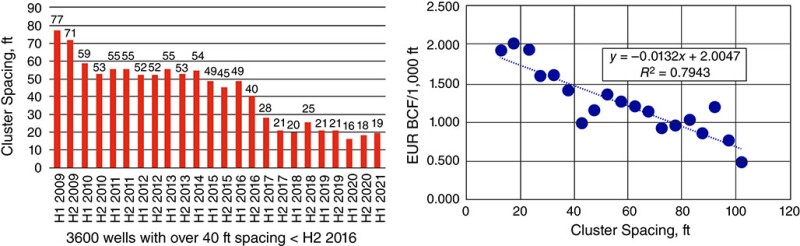

In one reservoir-pressure-monitoring pilot well drilled by ConocoPhillips in 2016 it was observed that 85% of the lateral interval was not being drained where the original completion had 50-ft cluster spacing. The observation well was 70 ft away from the producing parent well.

For wells that have relatively wide well spacings (over 600 ft), the post-stimulation total enhanced ultimate recovery (EUR) can be from three to four times the original EUR.

The two most active operators doing these types of stimulations in the Eagle Ford Shale (ConocoPhillips and Devon) are primarily doing protective treatments in parent wells to avoid significant child well EUR losses from asymmetric fractures.

In URTeC 3724057, Barba et al. demonstrated that when parent wells are restimulated following mechanical isolation the combined NPV10 of the post-stimulation production from the parent and the EUR preservation from the children is significantly higher than a new well’s NPV10.

The first-order child wells will have asymmetric fracs running home toward the parents and stranding 40% of the reserves on their distal side if a protective refrac is not done on the parent, as was shown in SPE 213075. The second-order child wells have an average of a 20% EUR loss.

Discussions with operators and presentations by upper management concerning this damage indicate that other than a few of the main players doing these subsequent stimulations, not all operators are aware of the detrimental effects of asymmetric fractures.

A major operator presenting at the 2023 SUPER DUG Conference mentioned that they saw positive production increases when Bakken parent wells had fracture-driven interactions (FDIs) from offset child-well fracs. When the author asked the presenter in the Q&A session if they were concerned about the EUR damage from the asymmetric fractures which resulted in these FDIs, he was clearly not aware that it was a problem.

For those who might not fully grasp the nuances of challenging parent-child interactions, consider the situation of parents supporting adult children who have not yet achieved independence. The goal for these parents is to encourage self-reliance and maturity, rather than a return to a dependent lifestyle. In the context of well management, the parent-well protective refrac is also designed to enable child wells to achieve their maximum production potential.

While these protective recompletions in legacy parent wells can provide a significant economic benefit, the treatments have not been accepted by all operators as a tool to significantly grow company asset value. There is little or no activity in areas where all the wells on a pad are legacy parent wells with no nearby children.

One of the larger operators doing these treatments indicated that it had no plans to redevelop any all parent well pads in the near future. A challenge this strategy brings is dealing with the multiple pressure sinks on legacy well-pad wells that would require all wellbores to be mechanically isolated and treated in a zipper pattern.

A four-well pad with P50 post-refrac recovery of 330,000 bbl of oil per well has an expected recovery of 1.32 million bbl of oil for a $11.2 million combined authorization for expenditure (AFE) (Barba 2022). The expected ROI is 3.6 to 1 with a 63% internal rate of return (IRR) and $20 million NPV10.

The author’s company is currently providing capital to participate in nonoperated positions in refrac candidates and is using the P50 criteria as a minimum hurdle for suitable candidates. With the above results, these expected minimum numbers should be competitive with the coveted Tier 1 locations that are supposedly increasingly scarce based on recent M&A market activity.

Do we really have an inventory problem? Or is it that operators do not fully understand the magnitude of the volume of remaining mobile hydrocarbons that are stranded in these wide‑spacing legacy wells? There are over 56,000 of these wide-spaced wells in the US at this time.

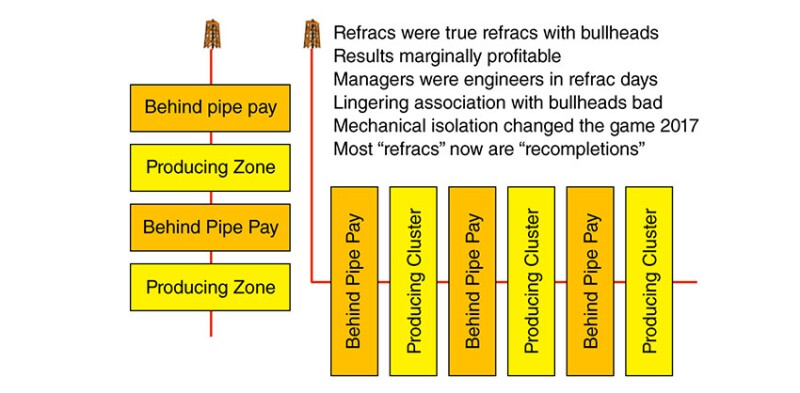

It is possible that a large part of the hesitation for operators to take refracs mainstream to achieve significant production growth is that we have been mislabeling these mechanically isolated subsequent stimulation treatments?

What is being done is a direct analog to stimulating a previously untreated zone above producing perforations in a vertical well. These treatments are typically called “recompletions” instead of “refracs.”

These behind-pipe zones frequently have close-to-virgin reservoir pressures and high producing rates after recompletions since the rock was not previously stimulated in organic shales. A “refrac” re-enters the same fracture and can only effectively recover the remaining reserves from the depleted current producing zones. Any new rock perforations added before the bullhead was pumped would be difficult to frac effectively. There are too many open perforations to implement extreme limited entry, and diverting material must be used. The depleted zones consume large volumes of the treatment until diversion hits the multiple phased perforation clusters.

Since phased perforations all have different stress fields acting on them it may take numerous diverter drops to seal off individual clusters much less raise the bottomhole treating pressures high enough to break down the higher closure stress new perfs.

To further demonstrate the difference between a less-desirable bullhead refrac and a better-performing liner recompletion, two separate studies were done to compare their relative performance. These studies, including URTeC 3855094, suggest that less than 10% of the clusters are producing with a bullhead refrac.

The first study in the Eagle Ford showed that in the same well a bullhead refrac increased the recovery factor by 0.9%. The subsequent liner refrac further increased the recovery factor by 9.1% or 10.1 times. The second study in the Barnett showed that mechanically isolated stages outperformed bullhead diverter stages by over 11.8 times per ft.

All said, it is important to understand the distinction between refracs and recompletions since recompleting virgin zones gets a lot more respect in the industry than refracturing existing perforations. That additional respect goes as far as allowing these previously uncompleted zones in vertical wells to have a PV20 asset value for P1 reserves that is universally recognized by reserve auditors.

Unfortunately, the majority of reserve auditors do not see the direct analogy when the wells turn sideways in organic shales. The only difference is the wellbore orientation yet somehow the logic changes.

With certain caveats, organic shale refracs check all the boxes in the SPE Petroleum Reserves and Resources Definitions (PRMS) for booking behind-pipe P1 reserves. Per the PRMS guidelines, they should have a PV20 discounted bookable P1 reserve value.

As an investor in refrac projects, this fine point is a double-edged sword. Yes, it would be good to get credit for behind-pipe assets that qualify for P1 status under PRMS. On the other hand, right now these assets can typically be purchased for their current PV10 producing value.

The P50 producing rate for pre-2016 Eagle Ford wells is 7 BOPD or approximately $250,000 in P1 PDP producing value. The PV20 of the post-refrac production for a P50 post-refrac recovery is $3.6 million. You do have to be careful what you ask for! On a macro basis if 1% of the Eagle Ford behind-pipe refrac candidates are booked, the total asset value add is $554 million.

Another issue is the lack of readily available data in the public domain on what treatments are refracs. Operators want to derisk their refracs, and the performance of existing refracs in their area is important to that derisking process.

Right now, the reporting process is not working reliably as some operators routinely avoid releasing any details about their refrac activity. There are a large number of wells with production spikes and identical “b” factor post-job declines that do not show any record of a liner being installed. A number of them do not have the second completion listed or have a FracFocus report. This is complicated by the large number of multiwell leases that have commingled production where the production increase from the refrac is seen in all pad wells due to the allocation algorithms used by Enverus or IHS.

The fact that the treatment was a liner recompletion or bullhead refrac could be included as check boxes in the existing FracFocus system. Many operators write on their state completion forms “see FracFocus” and provide only that information to the public. Another benefit of using the FracFocus system is the surveillance by a wide range of people observing our activity.

Keep in mind that the birth of the FracFocus database was the outgrowth of concerns from the Ground Water Protection Council (GWPC) and the Interstate Oil and Gas Compact Commission (IOGCC) to provide transparency to a skeptical public. With the numerous environmental advantages of refracs it may be beneficial to let all consumers of the FracFocus data know they are getting oil and gas from “recycled” wells that would have otherwise been nonproductive or abandoned much sooner without the recompletion.

Refracs also have a much lower carbon footprint than new wells and far fewer supply chain issues. If the metric of carbon generated per barrel for new wells is compared to refracs, the refracs have significantly lower carbon emissions to generate an incremental barrel. The carbon required to initially drill the recompletion candidate well has already been consumed by the plants and trees for quite some time. Lower-cost, lower-carbon footprint per barrel, delayed P&A liabilities, more-sustainable process, lower exposure to supply chain challenges, etc. are all strong benefits from recompletions. This is good news and the FracFocus observers from outside the oil field looking in might respond favorably to operators that are taking steps to responsibly lower their carbon per barrel.

Recompletions are a common sense sustainable lower-carbon option to add to new well drilling and completion programs for the organic shale world. Though, it does appear as Voltaire once said that “common sense is not so common,” as recompletions are neither getting the respect nor the capital they deserve.

And please, going forward, stop calling them refracs!

For Further Reading

URTeC 3724057 A Comparison of Latest-Generation Frac New Well and Refrac Results with Evidence of Refrac Reorientation by Robert Barba, Integrated Energy Services Inc; Justin Allison, Armor Energy LLC; Mark Villarreal, Enventure Global Technology.

URTEC 3855094 Hybrid Expandable Liner System: A Performance-Enhancing, Cost-Effective Alternative to Bullhead Refracturing by K. Eichinger et al.

SPE 213075 The High Cost Of Poor Child Protection: Economic Evaluation At The Pad Level With Primary Well Refracs by R.E. Barba.

Robert Barba brings more than 4 decades of expertise in the petroleum industry, specializing as an openhole wireline engineer, petrophysicist, product development manager, and completion optimization advisor. His work emphasizes the integration of petrophysics with completion and reservoir engineering to enhance well recovery. With a wealth of knowledge in both conventional and shale reservoirs, Barba earned the 2018 SPE Southwest North America Regional Formation Evaluation Award. As an SPE Distinguished Lecturer (1995–1996), he shared insights on optimizing completion designs through petrophysical and reservoir engineering inputs and was again nominated for the 2024–2025 DL season. A recognized authority on refrac candidate selection and best practices, Barba developed techniques for evaluating well performance that have been used on over 5,000 wells. Recently, he focused on refrac reorientation and parent-child issues facing the unconventional sector, contributing significantly to the field's literature.