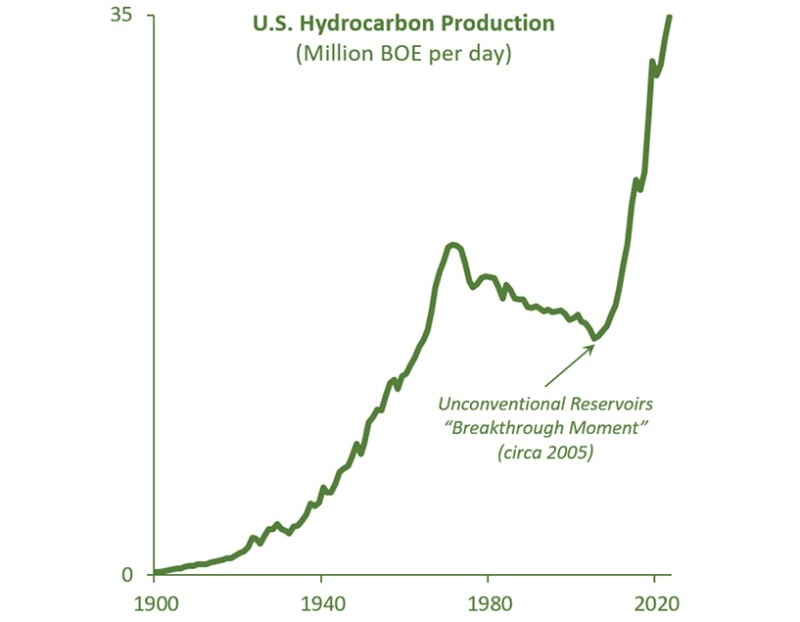

The development of efficient technologies for drilling and hydraulically fracturing horizontal wells has enabled the US to more than double hydrocarbon production since 2005 (Fig. 1), thereby providing unprecedented levels of energy security for America.

America’s doubling of hydrocarbon output has also held down the price of energy worldwide, and by doing so, accelerated global economic growth. And it has helped reduce the greenhouse gas (GHG) intensity of energy production by backing out “dirtier” forms of energy, such as coal.

Energy security—economic growth—reduced GHGs vented to the atmosphere: That’s a winning combination. One that America and many other countries have benefitted from immensely.

Given the enormous positive contributions, it is worth noting that 20 years ago, few if any in our industry foresaw the immense potential of this technology, seeing it as being only applicable for extracting gas from ultratight reservoirs like the Barnett Shale, if they were aware of the technology at all.

This oversight caused many companies to wait too long before deciding to pursue unconventional reservoirs and caused several of the “shale gas” pioneers to be late in recognizing that hydraulically fractured horizontal wells (HFHWs) could also be successfully applied in liquid-rich plays such as the Eagle Ford and Permian Basin. These are plays that today deliver far more value than that derived from the gas-prone reservoirs that comprised the initial suite of targets.

And while events have proven beyond a doubt that HFHWs are a powerful tool for economically extracting hydrocarbons from both gas-prone and liquids-rich unconventional reservoirs, it seems likely that many in our industry are overlooking a third significant application of this technology: The use of HFHWs to extract heat from the Earth’s crust that can be utilized to generate electricity.

Old Story, New Horizon

What makes this third application particularly compelling as an investment opportunity is that the primary physical challenge that needs to be overcome to achieve attractive rates of return is strikingly similar to that which the oil and gas industry had to surmount to make both gas and liquids-rich unconventional reservoirs economic.

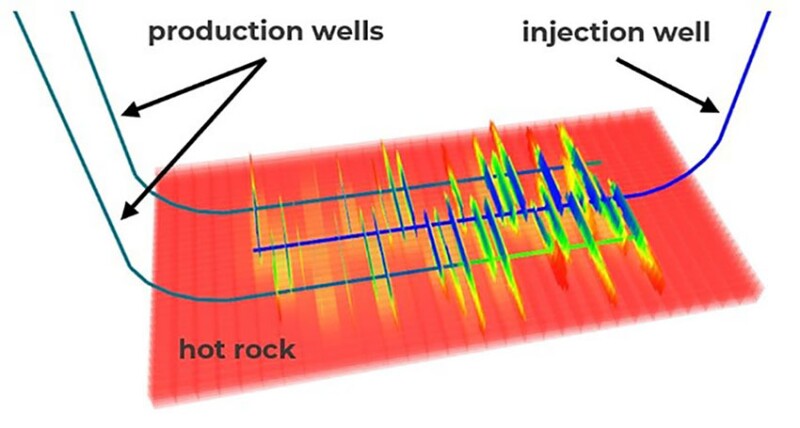

The key to success in all of these cases boils down to an ability to create via hydraulic stimulation a sufficiently large amount of conductive, connected, fracture surface area. With this, one can reliably expect per-well production rates to be economic given the extremely slow rate at which hydrocarbons—and heat—move through unconventional reservoirs and the hot, dry, basement rocks that contain the bulk of the world’s geothermal resources.

That converting from vertical to horizontal well geometries was critical for unlocking the potential of unconventional hydrocarbon reservoirs is now obvious, with this switch having allowed petroleum engineers to increase per-well fracture surface areas by several orders of magnitude. This move increased per-well flow rates by similar amounts (i.e., from subeconomic flow rates from hydraulically fractured vertical wells (HFVWs) to flow rates of thousands of BOE/D from HFHWs.

Surprisingly, given that 20 years has passed since the upstream oil and gas industry achieved this monumental breakthrough, the geothermal industry, which has since the 1970s tried with little success to use HFVWs to extract heat at commercial rates from the subsurface, has been slow to experiment with this “new” technology.

Only a single hydraulically fractured horizontal injector-producer well pair was brought online as of year-end 2023.

Undeniable Overlaps

Further to the point, these wells were drilled and completed not by a long-established geothermal operator but by a venture-capital-backed startup whose leaders all have oilfield experience (i.e., Fervo’s Blue Mountain, Nevada, enhanced geothermal systems (EGS) demonstration project wells).

That a single well pair is a very small sample size from which to draw conclusions about the robustness of a technology in a new application is inarguable, but what this single data point lacks with regards to “statistical robustness” it more than makes up for with outstanding drilling, completion, and production-related results.

This well pair has demonstrated:

- The use of modern oil and gas drilling technologies can dramatically reduce the time required to drill wells in hard, hot, basement rock formations.

- It is possible to both efficiently drill thousands of feet of horizontal section in these types of rocks and effectively hydraulically fracture them using the approaches commonly deployed by the upstream industry in unconventional reservoirs.

- Connectivity via hydraulic fractures can be established between horizontal injection and production wells.

- Reasonably consistent injection rates per perf cluster can be achieved along the entire length of an over 3,000-ft-long horizontal section, with no bias during injection towards perf clusters located near the heel of the horizontal section.

- Record-setting geothermal production flow rates can be attained from HFHWs (i.e., flow rates over twice as large as the highest-ever flow rate achieved from a HFVW).

Additional factors supportive of the economic attractiveness of using HFHWs to develop geothermal resources include:

- Scale. The volume of energy stored as heat within the Earth’s crust that is technically extractable is mind-bogglingly large, equal to thousands of times the world’s annual consumption of primary energy.

- Fit with upstream core competencies. The competencies critical for transforming the economics of EGS developments are ones the upstream industry already possesses, namely being skillful at characterizing subsurface resources; efficiently drilling and fracture-stimulating horizontal wells; injecting large volumes of fluid into the subsurface for the purpose of recovering resources; and managing large volumes of hot produced fluids and working with steam (such as is done in the SAGD fields of Canada).

- Knowledge. A considerable amount of additional data on the applicability of using HFHWs to develop geothermal reservoirs has recently been acquired by both the US Department of Energy-funded Utah FORGE consortium and by Fervo at their Cape Station project, the first-ever large-scale geothermal development using horizontal wells, with data from these two ventures expected to soon be available in the public domain.

- Optionality. The ability to experiment relatively cheaply with well designs and operational practices and rapidly incorporate learnings into future development plans will almost certainly be an enormously positive driver of value creation just as it has been for unconventional reservoir plays.

- Portfolio fit. When it comes to low-carbon technologies, which many upstream companies are pursuing, few technologies seem better aligned from a portfolio perspective since HFHW EGS can deliver clean, abundant, baseload energy, whereas most other low-carbon technologies are either ones that upstream has little chance of being competitive at (i.e., onshore wind and solar; batteries) or are technologies that don’t produce energy, with hydrogen being an energy storage and transportation medium, and carbon sequestration being a waste disposal business.

There Will Be Bumps in the Road

There will, of course, be challenges associated with commercializing EGS developments even for a company with both strong upstream and geothermal competencies, with some of the more prominent challenges and potential mitigations including:

- Premature thermal breakthrough. This has been the bane of the EGS industry over the past half-century, seemingly because fluid flow between vertical injectors and producers is concentrated over a relatively small amount of fracture surface area, which leads to rapid cooling given the large per-well volumes of fluid that need to be circulated to make EGS developments commercial.

This challenge is directly addressed by the orders of magnitude greater fracture surface area created by HFHWs, with further mitigations including the ability of operators to change well‑design parameters (e.g., well spacing and lateral length); use extreme limited-entry perforation techniques; deploy flow control technologies to restrict flow into thief zones; and refrac “problem wells.”

- Induced seismicity. There will be seismicity induced during EGS hydraulic fracturing and production operations (as there is whenever large volumes of fluid are injected into the subsurface). Therefore, although most “events” will not be detectable except by sophisticated measuring devices, techniques such as those used by the oil and gas industry to manage induced seismicity will be required.

- Equipment performance at high temperatures. It is more challenging to operate equipment at extremely high temperatures. Although, because the upstream industry has considerable high pressure/high temperature experience, and because there are enormous volumes of heat that can be extracted at relatively shallow depths in the range of 350 to 450°F, this should not be a significant barrier if an upstream company elects to pursue EGS.

Don’t Sleep on Geothermal

In closing, it seems surprising that few large upstream companies have aggressively embraced the use of HFHWs to extract heat from the Earth’s crust that can be used to generate clean, abundant, baseload electricity.

This is an opportunity that could scale quickly and deliver volumes of energy large enough to disrupt the global energy landscape much as unconventional reservoirs did in the oil and gas industry.

It is also an opportunity that could enable the transition to lower-carbon forms of energy that the world needs to address anthropogenic-driven climate change while concurrently providing SPE members with exciting career options—ones that will not only almost certainly provide viable employment opportunities for the duration of the careers of the current generation of petroleum engineers and geoscientists, but likely for millennia to come.

Greg Leveille was ConocoPhillips’ chief technology officer from 2016 to 2021. In this and prior leadership roles Leveille helped lead ConocoPhillips’ unconventional reservoir E&P program and its worldwide technology development efforts. Prior to his retirement, Leveille chaired SPE’s US Advisory Council and served on the Executive Advisory Board of the Unconventional Resources Technology Conference. Since retiring, Leveille has served as CEO of Tidal Wave Technologies LLC, a company focused on identifying breakthrough technologies that could transform the global energy landscape.