The Bakken and Three Forks formations have been treated as isolated pay zones since shale development took off in North Dakota more than a decade ago. Operators of the ultratight plays have acted on this thinking through drilling and completion programs that targeted each rock layer independently.

One of the companies to lead such programs is Hess Corp.

However, subsurface specialists within the regional stalwart have acquired new subsurface information over the past year that may steer the company toward drilling horizontal wells into just one of the two intervals—the more prolific Middle Bakken.

Craig Cipolla boiled it down this way: “I think the big takeaway here is that the data suggest the Middle Bakken wells can drain the Three Forks from 450 ft away.”

Stopping short of quantifying the co-production, Cipolla described it as “material” and added that production from the Three Forks up into Middle Bakken wells can be “significantly improved with the appropriate frac design.”

Cipolla is a principal completions engineering advisor with Hess and a coauthor of SPE 209164, which explains how a major observation well project led to that potential strategy-shifting conclusion.

That work involved testing a new well design that Hess said appears to generate 30–40% more oil over its baseline approach.

An especially novel idea not in the paper—but tied to the work it covers—involves producing oil from unstimulated wells that “harvest” hydraulic fractures from offsetting Middle Bakken wells. Hess calls this passive producer an augmented drainage development (ADD) well.

Cipolla confirmed that the first ADD well successfully flowed oil for a few months and that more attempts are planned.

He presented the paper and new insights on the ADD concept to industry peers in February at the Hydraulic Fracturing Technology Conference (HFTC).

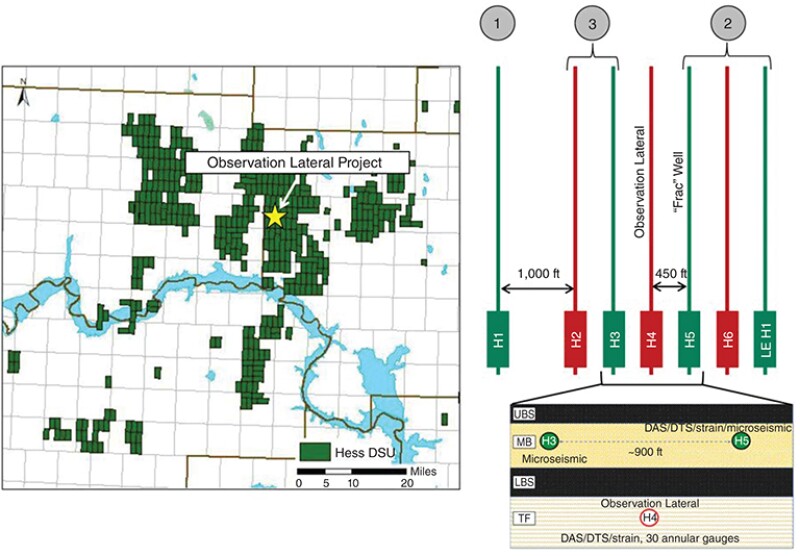

The experiment that it all revolves around began in late 2019 on a six-well pad about 10 miles north of the Missouri River. An incomplete outline of that pad follows.

- The Middle Bakken wells Cipolla referred to are 10,000-ft laterals spaced apart by 900 ft, which is significantly wider than the spacings the operator has used in recent years.

- Some 450 ft away in the underlying Three Forks is the lateral observation well (also 10,000 ft) that represents the centerpiece of the diagnostics project. Separating it from the Middle Bakken is what Hess describes as a “relatively thick” portion of the Lower Bakken interval.

- Observation well data (i.e., fiber optics and pressure gauges) and other data show Middle Bakken fractures intersecting all along the monitor lateral inside the Three Forks. Tracer and pressure data indicate that some of these “far-field” fractures achieved long-lasting conductivity, enabling the promising co-production.

While Hess continues to explore the findings from this test site, its paper suggests the new understandings on fracture growth and conductivity it has gained may add up to a fortune in value for its maturing asset. As the paper reads, “Even a small increase in well spacing of 20%, if accomplished with modest increase in well cost, could result in $100s of millions in added value.”

With two rigs running for most of last year, the operator produced an average of 156,000 BOE/D in the Bakken. With three rigs running now, Hess is aiming to complete around 85 new wells this year which it hopes will boost output by 9%.

Hess has not announced any major changes to its plans based on the recent revelations. However, it is testing an unspecified number of “Middle Bakken only” developments this year.

At stake is whether the operator can bolster its maturing inventory which was last reported to include around 2,100 high-return drilling locations at prices of at least $60/bbl.

The Subsurface Laboratory

The findings in SPE 209164 shed new light on the observation well pilot which Hess first spoke of at last year’s HFTC.

It was said at that the time that one of the biggest drivers of the research was to increase well spacings from as low as 350 ft to 700 ft and more—with an added goal to limit the need for Three Forks wells.

In the case of the observation project, the “more” translated to the four Middle Bakken wells laterally separated by 900 ft.

Offset 450 ft below two of those wells was a single lateral observation well drilled into the Three Forks. If this were a normal pad, then this well would have been hydraulically fractured just like the rest.

Instead, Hess installed a permanent fiber-optic cable into the well to watch for shifts in strain as fractures from the shallower wells approached and eventually intersected with it.

The well also had 30 pressure gauges cemented to the outside of the casing all along the 10,000-ft lateral.

With that pressure data still streaming in from this unusually large number of gauges, Hess believes it has in its hands the industry’s first direct long-term measurements of how far-field fractures produce based on multiple completion designs.

Additionally, the observation well was used for sealed wellbore pressure monitoring (SWPM). Commercialized by fellow shale developer Devon Energy, SWPM was used by Hess to quantify the arrival of far-field fractures. Comparisons of the fiber strain data and that from SWPM were shared at the conference in a separate paper, SPE 209129.

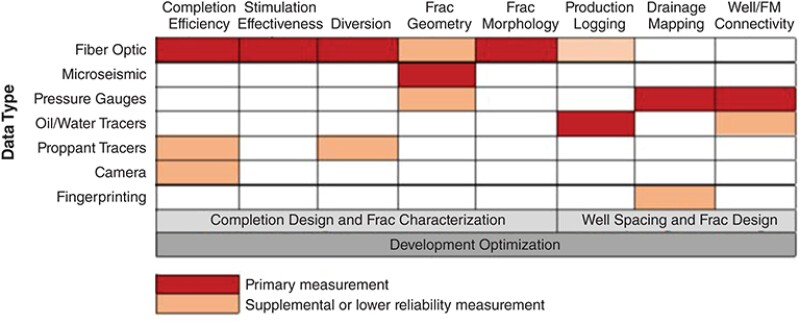

Not stopping there, Hess installed microseismic geophones in one of the Middle Bakken wells, a second deployment of fiber optics inside another, and oil/water/proppant tracers on multiple wells. Rounding out what amounts to a subsurface diagnostics wish list were downhole cameras to check for perforation cluster efficiency and geochemical fingerprinting.

All of this represents a huge and inordinate investment in subsurface diagnostics by shale-sector standards. Hess sees it paying off in spades though as it uses the data to calibrate the models that are so key to its decision-making.

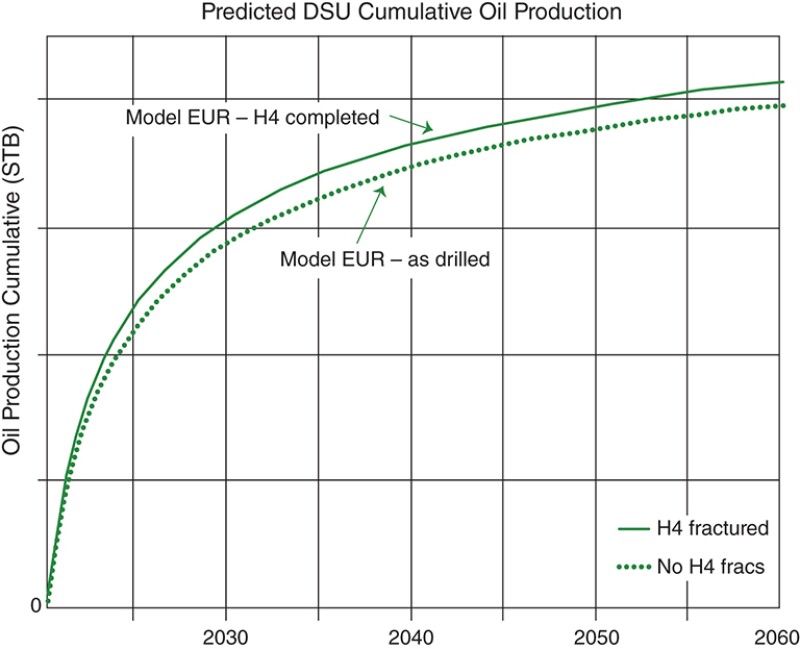

In a chief example, Hess modeled estimated ultimate recovery (EUR) rates on the drilling section to see what might happen if it fractured the Three Forks wellbore instead of using it purely for data gathering.

“It is a model,” cautioned Cipolla. “But what it suggested is that we get a 4% increase in EUR by fracking that well—and that we would actually degrade value by about 6%.”

In other words, chasing that extra bit of oil may in fact lead to overcapitalizing on the drilling section.

Breaking Barriers, Making Connections

As mentioned, vertically offsetting the observation well by 450 ft on either side were two Middle Bakken wells which were spaced apart by 900 ft. Such spacing has not been used regularly by Hess since 2013 when average stimulation treatments in the industry were at least three to four times smaller in terms of fluid and proppant loadings than they are today.

What the comprehensive data set showed Cipolla and others at Hess is how modern-day completions in Middle Bakken wells clearly generate fractures that grow downward through the Lower Bakken and into the deeper Three Forks.

Pressure gauges inside the well provide direct evidence that the offsetting fractures were impacting it somehow during every Middle Bakken stage completed. But Hess noted in the paper that this doesn’t mean each event was the result of a direct fracture hit, or a fracture-driven interaction (FDI), as some hits appeared to be more significant than others.

One of the critical nuances Hess adds to this is that some of the weaker responses it observed are likely due to fluids and pressure reaching the observer “via secondary hydraulic fractures, cement channels, annular fractures.”

Hydraulic fractures may also be initially connected between the wells but then disconnect due to poor proppant conductivity.

But some of the fractures appear to have stayed connected between the Middle Bakken and Three Forks. More than that, these fractures are flowing with oil.

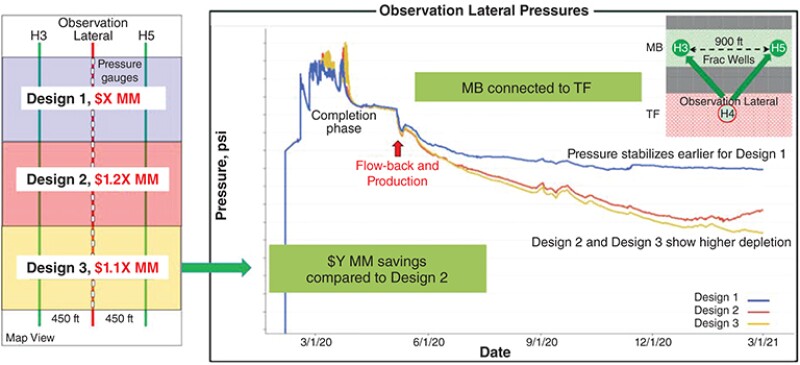

Cipolla pointed to a chart of pressure trends from the 30 gauges inside the observation well that revealed how the three completion designs it used on the pad were draining the Three Forks differently.

“I can’t show you the scale here, but this is significant depletion. This is not changes in 10s of psi—this is big,” he explained, while pointing at the divergence of two of the new designs vs. the current design at Hess.

The results shared here run counter to long-held beliefs about the Williston Basin which hold that the Lower Bakken largely contains the downward propagation of fractures, making it a “fracture barrier.”

Hess is offering its most compelling argument against that notion, but it is worth noting that other operators including Ovintiv and Devon Energy have recently drawn similar conclusions.

Cipolla attempted to settle the question of connectivity by saying that the Middle Bakken and Three Forks are “connected everywhere” with likely only a handful of exceptions.

This is partly based on log data that show its study area involves what Hess says is a 50-ft section of the Lower Bakken between the Middle Bakken and Three Forks.

“That’s about as thick as it gets in the Bakken,” said Cipolla, who added that the pressure gauge data in the observation well continues to show a connection exists more than a year after the completions took place.

“It’s still there,” he said. “That was really, really significant for us.”

Productivity Enables Wider Spacing

Cipolla issued caution during his remarks by stressing that 900-ft spacing of Middle Bakken wells is not necessarily what Hess considers to be the ideal distance in the Bakken.

The modeling results it shared at HFTC are intended to “guide our development and come up with the optimum—which is difficult and we’re still working on that.”

Ultimately, the data point toward a reduction in the number of wells Hess will drill going forward.

In recent years, the company has developed pads with up to eight wells: one parent well, four Middle Bakken wells, and up to three Three Forks wells.

Potential developments being considered could draw down the number to three to five wells per section. This aligns with another goal Hess shared at last year’s HFTC to maintain production in the Bakken and Three Forks with around 40% fewer wells than is currently required.

To do that, the operator will need a new completion design that is purpose-built to co-produce the Middle Bakken and Three Forks.

And while most details are not shared in SPE 209164, the operator said it found one promising experimental completions package through the observation well project.

The new recipe costs 10% on top of the usual well design, but field data shows it may produce between 30-40% more oil.

“We have possibly a design that can increase drainage and yet a modest increase in cost,” said Cipolla, echoing the paper he coauthored.

“This is something we all want to do—increase performance and then reduce costs, or not increase them too much.”

“Design 3”

The connection Cipolla spoke to is not uniform across the observation well since Hess tested three different completion designs. As referenced in the paper, “Design 1” is the operator’s standard package while “Design 2” and “Design 3” represented new test designs.

Tracers were used to validate that both Design 2 and Design 3 outperformed the status quo—producing 30% to 40% more oil.

But ultimately, it was Design 3 that demonstrated the most sustained connections between the Middle Bakken and Three Forks wellbores.

Design 3 also had a 10% lower water cut than Design 2. This is in part why Hess acknowledges that Design 3 could have simply tapped into more productive and less water-laden rock.

However, the operator counters that by noting that its fracture simulations predicted that Design 3 created a larger productive area than the other two designs.

Despite some of the unknowns involved, the Hess authors issue this positive impression: “The vision of significant optimizations in well spacing using advanced completion designs could be realized given the performance of Design 3.”

In terms of what Design 3 consists of, the operator is withholding most of the key specifics. That said, Hess does acknowledge in the paper that the recent data set supports using limited-entry completions, increasing the number of clusters per stage, and decreasing overall stage count.

The fate of Design 3 remains uncertain as Hess believes that despite its performance in the observation project, there might be an even more optimal formula for 900-ft well spacing or distances that stretch beyond that.

Harvesting Fractures With ADD Wells

In his concluding remarks at the conference, Cipolla tied the observation well project to one of the operator’s next and particularly novel pilots.

Late last year, Hess went to the field for another big data-acquisition project but this time it did something never heard of before in the shale sector. It indirectly stimulated a Middle Bakken well with hydraulic fractures originating from an offsetting well in the same layer.

Put another way, Hess has designed a well that produces via intentional fracture hits. This is the ADD well concept in a nutshell.

Cipolla said, as of the time of the conference, that the well produced for 3.5 months over a 5-month period. It was shut in for about 6 weeks during that span for a fishing operation and no other production details have been shared.

In terms of what this well looks like, Cipolla said its “uncemented with a slotted liner—that’s it.” He added that its role is to “harvest the far-field fractures” of other Middle Bakken wells.

The idea also ties back to work Hess presented 2 years ago at HFTC which came from the same pad as the first observation well project.

The parent well on the pad, aka the H1, had been producing for more than a decade when Hess used it for microseismic monitoring to map drainage, or what the firm calls microseismic depletion delineation (MDD).

MDD involves pumping water into a wellbore to measure reservoir depletion as a function of the microseismic responses that are picked up. The project is the focus of SPE 199716, of which Cipolla is also a coauthor. The paper’s conclusion uses language that tracks very closely with the newly proposed ADD well:

“The MDD showed drainage extended approximately 500 ft on either side of the H1 lateral. Given the relatively ‘old style’ completion using an un-cemented pre-drilled liner, this suggests that even poorly propped and/or unpropped fractures can be productive.”

Following the first ADD pilot, Cipolla said more will be attempted this year.

This might be of particular interest for other Bakken operators. Still, there’s a big caveat for the wider shale sector since among other things, FDIs in the Bakken and Three Forks function differently from those in many other tight-oil plays.

Thus, what Hess is testing here may not work outside of the region. And aside from that, Hess doesn’t know how this idea will scale within the Bakken.

Striking a tone of cautious optimism, Cipolla remarked, “This could crash and burn—this ADD concept—but it might not.”

For Further Reading

SPE 209164 Observation Lateral Project: Direct Measurement of Far-Field Drainage by Craig Cipolla, Jennifer Wolters, Michael McKimmy, Carlos Miranda, Stephanie Hari-Roy, Aicha Kechemir, and Nupur Gupta, Hess Corp.

SPE 209129 Evaluating Stimulation Effectiveness with Permanent Optical Fiber and Sealed Wellbore Pressure Monitoring: Bakken Case Study by Craig Cipolla, Michael McKimmy, Stephanie Hari-Roy, and Jennifer Wolters, Hess Corp.; and Jackson Haffener, Kyle Haustveit, and Mouin Almasoodi, Devon Energy.