Rystad Energy shared details this week of a new report that suggests the oil and gas industry may see hundreds of thousands jobs replaced by robotic roustabouts by decade’s end.

Advanced robotics remains an emerging technology arena for the industry, with limited field deployments. But, if there is a major industrywide drive, Rystad concludes that the expansion of this arena would reduce annual overhead costs by billions of dollars.

The savings would come largely as the result of eliminating one out of every five jobs in the industry's drilling, operations, and maintenance segments by 2030.

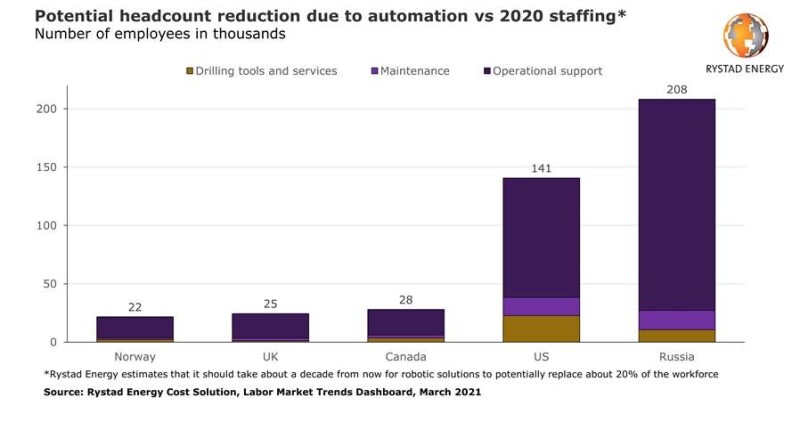

Under Rystad’s scenario, this robotic revolution would see current headcounts in the US oil and gas industry fall by around 140,000. In Russia, more than 200,000 field-oriented jobs are at risk of being lost to robots. Canada, the UK, and Norway each may see workforce reductions between 20,000 and 30,000.

Robotic drilling systems, one of the more mature components of the oil field's robotic spectrum, are set to reduce average drilling rig crew sizes by 20 to 30%. If these figures are applied to just the US onshore and offshore sectors, Rystad estimates a windfall of $7 billion in labor cost savings.

Robots built for inspection, maintenance, and repair (IMR) duties also are seeing significant uptake in the offshore business. Subsea IMR systems took an early lead here, but, as technological obstacles are removed, Rystad expects IMR robots will find a permeant place on many platform topsides.

A Taste of What's To Come

As evidence that the technological shift is already upon us, Oslo-based Rystad points to recent deployments of robotics and advanced software that is automating key components of the overall drilling system.

High on the list is the subsea remotely operated vehicle market (ROV), where the potential to eliminate expensive human-operated ROVs and their support vessels has driven the rise of resident ROVs that can work below the waves independently.

- Kongsberg Maritime’s Eelume: A self-propelled robotic arm that can perform a wide variety of IMR activities, including the operation of valves and chokes. The technology has been deployed by Equinor at its Asgard field.

- Diamond Offshore’s Blowout Preventer (BOP): A digital twin of the BOP is used to assess the health of its hydraulic and electrical systems. This enables preventative maintenance to reduce downtime and improves safety while also enabling advanced training for rig personnel.

- Transocean’s safety system: Wearable tracking devices on all personnel are used to automate safety protocols. If a crew member is too close to drilling equipment, an alarm is trigged and the equipment is automatically shut down.

We Are Not There Yet

Sumit Yadav, an energy service analyst at Rystad, issues caution on the actual return industry should expect to see on its investment, at least initially.

“Despite the huge potential of robotics, operators should be aware that these savings will be partially offset by the considerable investments required for the adoption of these solutions, which may vary depending on the cost structure and whether the robots are owned or leased," Yadav said.

The advanced BOP technology used by Diamond Offshore offers one example of how business models may change because of the high price tags of automated technology. In 2017, the driller and its BOP maker, GE, entered into long-term lease contracts that provided incentives based on the digitized well control equipment’s reliability.

Rystad also notes in its report that, “while the emergence of robotics in the oil and gas industry seems inevitable,” it also expects widespread deployments will take a few years. Robots first need to prove they are truly reliable workers, especially in “complex 3D environments” such as offshore facilities.

One innovation aiming to break past this barrier comes from the renowned robotics developer Boston Dynamics. The firm’s commercial inspection bot, described as a “robot dog” and appropriately named Spot, was deployed last year by Aker BP on a facility in the North Sea.

Another hurdle Rystad cites as critical to widespread adoption involves how humans will effectively talk to their robotic coworkers. The consultancy found that the advanced communications systems needed to do this are “both complex and costly.”

The unpopularity of this transition must also be considered. Rystad says to expect resistance from labor groups seeking to protect their stakeholders from unemployment.

Traction may also need to move at the pace set by regulatory bodies charged with ensuring robotics and automation are able to meet health, safety, and environment criteria designed for human-controlled systems.

The 2021 Offshore Technology Conference to be held 16–19 August in-person in Houston with virtual components includes sessions discussing advances in robotics, enabling normally unattended facilities, and topside innovative processing and production. See more related content in the OTC technical program here.