The term “new energy economy” broadly refers to the transition to a low-carbon future for sustaining human development while reducing CO2 emissions.

Such a shift is considered to be the third energy transition of the modern era, after the shift from biomass to coal as the primary source of energy in the early 1900s, followed by oil overtaking coal’s dominant position in the 1960s–1970s.

This trend towards decarbonization (i.e., diversification from carbon-intensive fossil fuels to sustainable greener energy feedstocks and carriers) is motivated by the understanding that emissions need to be reduced to moderate the potential impacts of global temperature rise on future climatic changes.

Strategies common to proposed decarbonization pathways include

- Improving energy efficiency (i.e., slower increase in energy demand compared to GDP/population increase).

- Increasing energy supply from renewable sources (i.e., wind, solar, geothermal, nuclear) coupled with hydrogen underground storage (HUS) as a way of storing surplus electrical energy.

- Switching to low-carbon energy carriers (i.e., hydrogen) for end‑use applications in transportation, buildings, and industry.

- Removing carbon emissions, via carbon capture, utilization, and storage (CCUS), from fossil-fuel-fired power plants and hard-to-abate industrial sources.

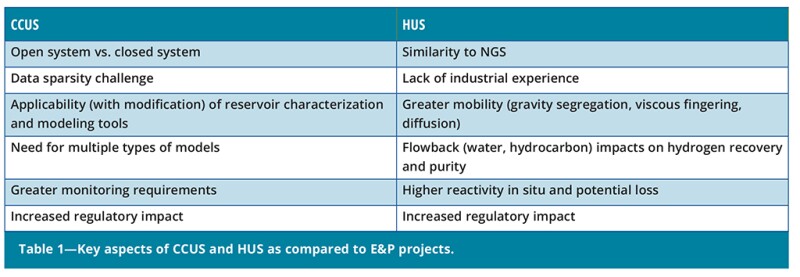

The key takeaway for readers is how the two subsurface-oriented decarbonization strategies—CCUS and HUS—are relevant for application/adaptation of expertise from the exploration and production (E&P) sector of the oil and gas industry. Their rise will be built upon decades of experience with CO2-EOR, gas injection, produced-water disposal, and underground natural gas storage (NGS).

Carbon Capture, Utilization and Storage (CCUS)

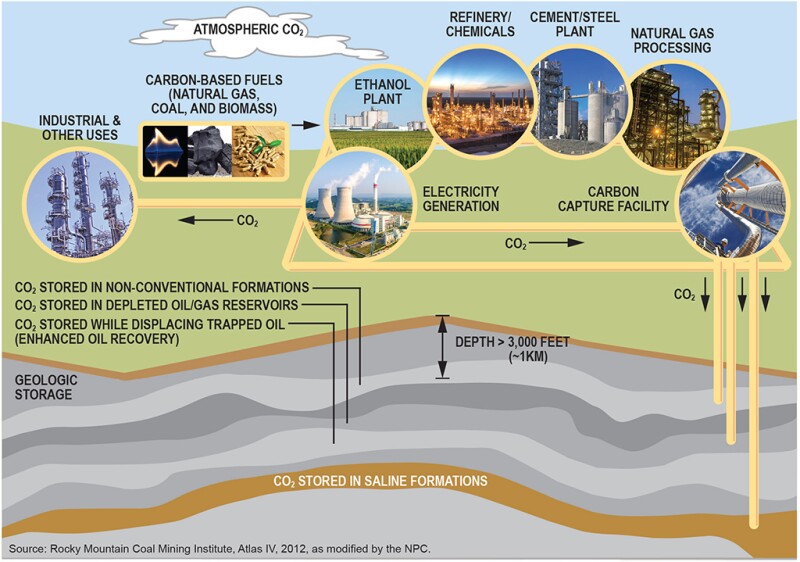

As shown in Fig. 1, CCUS involves capturing CO2 from a fossil-fuel-fired power plant or industrial facility and processing it to a practically pure form, transporting it to a nearby geologic storage site using pipelines, and injecting it into saline aquifers for long-term sequestration or depleted oil/gas fields for enhanced oil recovery (EOR) and associated storage.

Research and field demonstration projects over the past few decades have demonstrated that CCUS is a viable technology for curtailing atmospheric CO2 emissions buildup.

Some of the key elements of CCUS projects and their overlap with corresponding E&P expertise are summarized below.

Storage resource assessment. This step involves an estimation, especially during the pre-injection appraisal and permitting phases, of the quantity of CO2 that can be stored in the target formation. It is important to distinguish between (a) volumetrics-type approaches appropriate for deep saline aquifers which can be regionally extensive and hence, akin to infinite-acting reservoirs, and (b) voidage-replacement type approaches appropriate for depleted oil/gas fields which are essentially closed reservoirs.

Also, SPE has recently developed the CO2 Storage Resources Management System (SRMS), analogous to the Petroleum Resources Management System (PRMS), to provide an accepted and recognized system for quantifying, categorizing, and classifying storage resources.

Reservoir characterization. The goal is to understand the spatial extent, boundaries, flow barriers, and rock/fluid properties of the target storage formation. In addition, geotechnical properties of the caprock and overlying seals, location of underground sources of drinking water (USDW), and presence of conductive fractures and faults that could act as leakage pathways or trigger injection-induced seismicity are also important for CCUS projects.

The challenge of data sparsity is generally a concern for saline aquifers, as projects will typically have data only from one dedicated site‑characterization well and perhaps a handful of legacy wells (from oil and gas exploration and/or subsurface waste injection).

Pressure propagation and CO2 plume modeling. As with E&P projects, static and dynamic reservoir modeling are fundamental to operational management of CCUS projects. The metrics of interest are (a) pressure buildup in the injection well, caprock, and storage formation, (b) CO2 plume migration extent, and (c) delineation of the Area of Review, i.e., a region surrounding the injection well where USDW may be endangered because of injection-induced excess pressure buildup.

Conventional geologic modeling and simulation workflows/tools from the oil and gas industry have been adapted and applied for CCUS projects, along with simplified approaches such as sharp-interface models and fractional-flow models, which may be more appropriate for project developers and/or regulators. However, the impact of data sparsity is an important constraint, especially for history matching of models to observational data collected from a limited number of monitoring wells.

Monitoring of reservoir performance. Regulatory guidance for geologic sequestration wells generally stipulates more involved monitoring of system evolution and storage integrity compared to E&P injection wells. Required detailed surveillance involves geophysical surveys, geochemical sampling, geomechanical measurements, and dynamic pressure and temperature sensing in the storage reservoir and caprock. Also, detailed documentation of monitoring, verification, and accounting is needed for receiving tax credits or trading carbon permits.

Hydrogen Underground Storage (HUS)

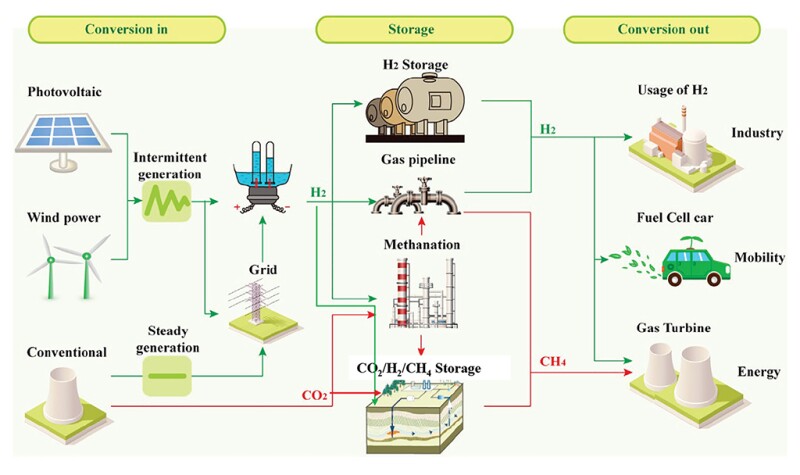

Fig. 2 depicts the hydrogen value chain, which includes (a) production of green hydrogen from renewable sources or blue hydrogen from fossil-fuel-based sources in conjunction with CCUS, (b) storage in physical containers or underground geologic formations, and (c) end use in industry, transportation, and energy sectors. HUS is particularly attractive for managing the intermittency of renewable power generation and is similar in concept and execution to active underground NGS storage projects in aquifers, depleted oil/gas fields, and salt caverns.

Some of the key elements of HUS projects and their overlap with corresponding E&P expertise are summarized below.

Reservoir characterization/development. The characterization needs for saline aquifers is the same as was discussed earlier, whereas depleted oil/gas fields will have a pre-established database for reservoir characterization. The construction of salt caverns via brine circulation for HUS would be similar to that for NGS, albeit with the needs for better geomechanical characterization and modeling of salt creep, cavern integrity, and fluid leakage.

Well deliverability. The productivity of a hydrogen well can be evaluated using standard NGS well-deliverability equations that include both Darcy and non-Darcy flow components—adjusted for hydrogen properties. Similarly, the common equations for wellbore pressure and temperature changes during injection/production need to be adapted for hydrogen-specific conditions. HUS projects can also benefit from the application of standard workflows from inflow performance and nodal analysis for integrating surface, wellbore, and subsurface elements.

Dynamics of fluid withdrawal. Dynamic modeling of HUS can build on NGS and CCUS tools and experience, but complications caused by high mobility of hydrogen (i.e., gravity segregation, viscous fingering) need to be addressed in simulation design and operational planning. Another challenge is the modeling and management of water up-coning (from aquifers) and hydrocarbon recovery (from depleted oil/gas fields) during hydrogen production. Also, the high levels of hydrogen diffusivity and reactivity (with rock, in situ fluids and bacteria) require assessment of reservoir and caprock integrity using coupled compositional flow and bio‑geo-chemical reactive transport models.

What Skills Need Updating?

We believe that the foundational preparation for the subsurface science and engineering aspects of both CCUS and HUS should come from traditional petroleum engineering and geoscience curricula via core courses in reservoir characterization, wellbore hydraulics, and reservoir engineering. In addition, several specialized courses would be required to address the CCUS and HUS industry-specific needs, as follows.

Foundations of CCUS. CCUS rationale, CO2 capture, pipeline transport, geological storage basics, aquifers vs. depleted oil/gas fields, monitoring, risk analysis, permitting, and global status/outlook.

Foundations of HUS. Hydrogen usage rationale, pipeline transport, geological storage options (salt caverns, depleted gas/oil fields, aquifers), cavern engineering, geological characterization, well deliverability, reservoir mechanics, and risk analysis.

Advanced reservoir science and engineering for CCUS and HUS. Storage resource estimation, source-sink matching, monitoring, verification, and accounting (MVA), well deliverability, injectivity and plume migration models, and pressure and rate transient analysis.

Risk analysis and permitting for CCUS. Risk source identification, consequence analysis, risk management and mitigation, regulatory framework (EPA class VI permitting, EU CCS directive), regulatory compliance, and MVA documentation.

These courses can be incorporated into existing petroleum engineering and/or geoscience curricula as specializations and/or certificate programs.

They can also be introduced in the continuing education marketplace through providers such as training consortia or university extension programs. Some key aspects of CCUS and HUS as compared to typical E&P operations are summarized in Table 1.

Future Prognosis

The pace of the current energy transition will depend on (a) availability of low-carbon technologies deployable at scale, and (b) societal demands linked to cost-benefit considerations.

Given the magnitude of capital inflows required and the complex restructuring of the supply chain, existing oil and gas companies can play a major role from both techno-economic and human capital perspectives.

To that end, we have discussed how relevant E&P expertise can be leveraged to meet the needs of the nascent CCUS and HUS marketplace. We strongly believe that the capabilities of oil and gas professionals are readily adaptable for such projects with appropriate re-education and training, and our industry can contribute not just with technology but also with skilled manpower.

On a related note, petroleum engineering skills are already being applied to geothermal energy, another emission-free and fully dispatchable power and heat source that will also play a critical role in the energy transition.

In closing, we recognize that the aspirational goals set forth in most decarbonization plans and net-zero scenarios would require a significant switch from fossil fuel to low-carbon sources. However, with the continued increase in energy demand to improve quality of life (especially in developing countries), energy transition in the near term will most likely reduce to energy diversification as a pragmatic solution.

A variety of energy sources including renewables and fossil fuel (primarily natural gas) will most probably be utilized in conjunction with CCUS and HUS, with CO2-EOR used as a bridge technology in the interim. As such, the technology and human resource base from the E&P sector is poised to play a vital role in the new energy economy—regardless of the trajectory of low‑carbon pathway adoption.

Acknowledgments

We thank Joy Frank-Collins (Battelle) for her careful review of the manuscript. Support for preparing the paper was provided by US DOE‑NETL’s Midwest Regional Carbon Initiative at Battelle Memorial Institute and Model Calibration and Efficient Reservoir Imaging (MCERI) JIP at Texas A&M University.

For Further Reading

SPE 210372 Adapting Petroleum Reservoir Engineering Principles to Carbon Capture & Sequestration (CCS) and Hydrogen Underground Storage (HUS) Projects: Opportunities and Challenges by Srikanta Mishra, Battelle Memorial Institute, and Akhil Datta-Gupta, Texas A&M University.

Power-to-Gas-Based Subsurface Energy Storage: A Review. Renewable and Sustainable Energy Reviews, by J. Ma, Q. Li, M. Kühn, and N. Nakaten, 2018.

The Uncertain Bright Future of Underground Hydrogen Storage by Trent Jacobs, SPE, JPT, April 2023.

Srikanta Mishra, SPE, is technical director for geo-energy modeling & analytics at Battelle Memorial Institute, the world’s largest not-for-profit private R&D organization. He holds a PhD in petroleum engineering from Stanford University. Mishra is a recognized expert on understanding and communicating model and data-driven insights for various geo-energy problem domains and foundational aspects of new energy economy-related subsurface technologies such as geological carbon storage and hydrogen underground storage. He received the 2022 SPE Data Science and Engineering Analytics Award, the 2021 SPE Distinguished Membership Award, and served as an SPE Distinguished Lecturer on big data analytics during the 2018–2019 season. He is the author of approximately 200 technical publications, one textbook, and three compiled volumes. He is also a popular instructor of short courses on data analytics and energy transition for SPE as well as other organizations. He may be contacted at mishras@battelle.org.

Akhil Datta-Gupta, SPE, is regents professor, university distinguished professor, and L.F. Peterson Endowed Chair professor in the Harold Vance Department of Petroleum Engineering at Texas A&M University. His research interests include high-resolution flow simulation, petroleum reservoir management/optimization, large-scale parameter estimation by use of inverse methods, and uncertainty quantification. Datta-Gupta holds a PhD in petroleum engineering from The University of Texas at Austin. He is an SPE Honorary Member and received SPE’s 2003 Lester C. Uren Award and 2009 John Franklin Carll Award. He was elected to the US National Academy of Engineering in 2012. Datta-Gupta may be contacted at datta-gupta@tamu.edu.