Matt Mantell wasn’t always sure that completing horizontal wells with wet sand was going to be as efficient as using smooth-flowing dry sand.

But after proving how well it does work, and how much money it saves, the completions engineering advisor with Chesapeake Energy said the plan to use wet sand at every possible opportunity is moving “full-speed ahead.”

Wet sand represents a new trend in the US shale sector that has spread from operator to operator. After the sand is washed free of unwanted particulates at the mine, it has historically been dried before being delivered to a wellsite.

Wet sand is instead loaded straight from decanting piles. The gas-burning dryers are left off.

Chesapeake’s numbers show that by using wet sand instead of dry sand, the operator saves about $11/ton. On a 10,000-ft lateral using 3,600 lb/ft, this translates to a savings of nearly $200,000, or 2% off the total well cost.

In framing the impact of these reductions, Mantell said, “It’s right there with the type of shift we’ve made over the last few years to more regional sands. You’re looking at an opportunity to continue reducing the logistical cost, the trucking cost, from the mine to the wellsite.”

Oklahoma City-based Chesapeake emerged from bankruptcy protection in February and is looking forward to leveraging the shale sector’s latest cost-saving evolutions in its renewed drive to become a low-cost shale producer.

While this is easier said than done, wet proppants appear to be low-hanging fruit.

As Chesapeake’s example demonstrates, successful adoption involves minimal trial and error. It also shows that the outlook for this trend will be bolstered by its lower energy inputs, which means wet-sand wells can boast slimmer carbon footprints.

Gusto may be far from peaking, too. Chesapeake predicts that future mines will become small and mobile, further lowering capital costs.

Learning the Ropes

The operator’s first go with wet sand came in August 2019 during a refracturing operation at the Eagle Ford asset it acquired that same year in its purchase of WildHorse Resource Development. The trial in southeast Texas involved pumping wet sand into just a few stages, but it offered a low-risk opportunity to work through the hiccups that wet sand can introduce.

One relatively minor issue discovered early on involved getting the wet sand to load evenly onto the conveyer belt that feeds the blending unit. The clumpy nature of wet sand led to a few big slugs of it hitting the blender all at once, making it difficult to meter just how much was going in.

The issue was quickly worked out in part by simply paying greater attention to how the sand was loaded and unloaded, with the focus on spreading it out as evenly as possible.

Adam Hoffman, a lead completions engineer in Chesapeake’s Eagle Ford asset, said the biggest learning, though, was that there is a “real fine line” between sand that is wet and sand that is too wet. If the moisture content by weight is above 6%, those loading issues become inevitable.

Last year, Chesapeake engineers took their notes from the trial to a set of new wells in the same field. This time, their goal was to use 100% wet sand.

The mark was hit over a 54-day period, during which more than 282 million pounds of wet sand were pumped down eight wells on three pads. That proved enough to convince the company that wet sand would not slow it down.

“We were expecting there was going to be a learning curve, because obviously this was something new,” said Hoffman. But he said what surprised him and the team the most “was how quickly we adapted to this process.”

It took just a week for the completions team to get a full handle on the change. After that, crews were hitting the same efficiency targets as they had with the dry variety.

“We really didn’t skip a beat,” added Hoffman. “The project went about as good as we could have expected.”

Earlier this year, Chesapeake did its first wet-sand completions in Louisiana’s gas-rich Haynesville Shale where nearly 69 million pounds were used in three wells. With this project declared a success, the operator now knows transferring the practice across its business units can be done almost seamlessly.

Sharing Over the Lease Line

Months before Chesapeake pumped its first load of wet sand, engineers in the company were reaching out to peers at Ovintiv to ask about the process.

The Denver-based shale producer is one of the earliest adopters of wet-sand completions in the Permian Basin and invited a team from Chesapeake to see how it all worked. “That gave us the confidence that we could get it done,” said Brad Goebel, a supply chain manager at Chesapeake.

When Chesapeake decided to execute at the full-pad scale, it tapped two of the same wet-sand equipment companies Ovintiv used. Filamar Energy Services provided some of the essential know-how, and PropX, which published the first conference paper about the process last year, provided the equipment.

The only concern raised from the pressure-pumping provider during that first single-well trial involved how to modify its processing and blending equipment so that it could properly take in the wet sand. With a few small adjustments, and no new technology, the problem was solved.

Since then, service providers appear to have become better adapted. “Every pressure pumper that we engage with has said that they can pump wet sand, no problem,” said Goebel.

Wet Sand Is Green, May Get Greener

Chesapeake is confirming that the upsides of wet sand also extend to the health and environmental arenas.

Wet sand essentially eliminates the potential for respiratory concerns caused by the plumes of silica dust that were once omnipresent near blender units—often placing those areas off-limits to workers without a respirator.

But the biggest driver of discussion in the industry today is around how to lower carbon dioxide (CO2) emissions. Here, wet sand appears to have a big role to play.

In its eight-well project in Texas, Chesapeake figures it saved more than 49 MMscf of natural gas by not needing to run the drying unit at its mine. This prevented 2,645 metric tons of CO2 from being released, according to company numbers.

Mantell expects the next advance in proppant logistics is mobile wet-sand mines.

“The potential for small, modular mines that don’t require a dedicated gas supply opens up a new realm,” he said. “The closer you are to the wellsite, it’s not just an economic benefit, but there’s potentially a tremendous environmental benefit in terms of lower CO2 emissions.”

The trick mobile mines must pull off is to find the right distance between different operators’ activities. As tallying emissions becomes a routine part of shale-sector accounting, every mile counts.

Chesapeake estimates that reducing the roundtrip distance from a sand mine to a four-well pad from 150 miles to 50 miles would save about 50,000 gallons of diesel and prevent up to 520 metric tons of CO2 from being emitted.

Focus on Quality Control

One advantage that Chesapeake shares with some of its peers in Texas is that when it performed its first wet-sand completions more than a year it ago it had just opened a brand-new sand mine that it obtained through the acquisition.

In addition to enabling it to benefit fully from the cost savings on the gas supply, owning the mine also gives Chesapeake total control over the critical moisture levels. Although, this was not the case in the recent Haynesville operation.

Chesapeake had to instead source wet sand from a regional mine operator, which served as a test to see if the wider market could meet the sensitive specs.

“It made us focus more on the communication and we made sure we were relaying back to the mine what moisture content was working and what wasn’t,” said Colby Arnold, a lead completions engineer in Chesapeake’s Haynesville asset.

He said this feedback loop allowed the mine to “fine-tune” the moisture by the time the third well was completed, which had “very few moisture-related issues.”

A different problem occurs when wet sand runs dry—as in it is no longer available. This issue could not be avoided in the Haynesville jobs because the high-pressure formation demands higher proppant concentrations than are needed in the Eagle Ford.

“They weren’t quite able to keep up,” Arnold said of the sand supplier. “So, there is still work to be done on that side. We need to refine the process in order to get to a point where we’re not waiting on sand.”

Questions on Production Uplift

While it is a proven money-saver, one unknown is whether wet sand has any positive effect on production. Chesapeake’s most recent completions in the Haynesville involved wet sand with 40/140-mesh sizes vs. the previous dry-sand recipe that called for 100-mesh.

It was a similar change at its Texas operations where grain sizes of 40/200‑mesh were used in most of the wells. This is a quite a bit smaller sand-grain mix than the 100-mesh lead ins and 40/70-mesh bulk treatments of dry sand the operator was used to pumping.

Grains of 200-mesh or smaller, often called microproppants, have been marketed as premium products that can enhance production. Studies from proppant makers argue that the tiny sand grains boost oil flow by propping open secondary-fracture networks that are too narrow for larger mesh sizes to reach.

Because the simplified wet-sand process limits the number of fines that are sifted out or blown away by the wind, microproppants can now be bought at a steep discount.

Chesapeake found that the 200‑mesh grains in its Eagle Ford completions represented between 7–10% of the total volume, which was a higher proportion than it had ever seen with dry sand.

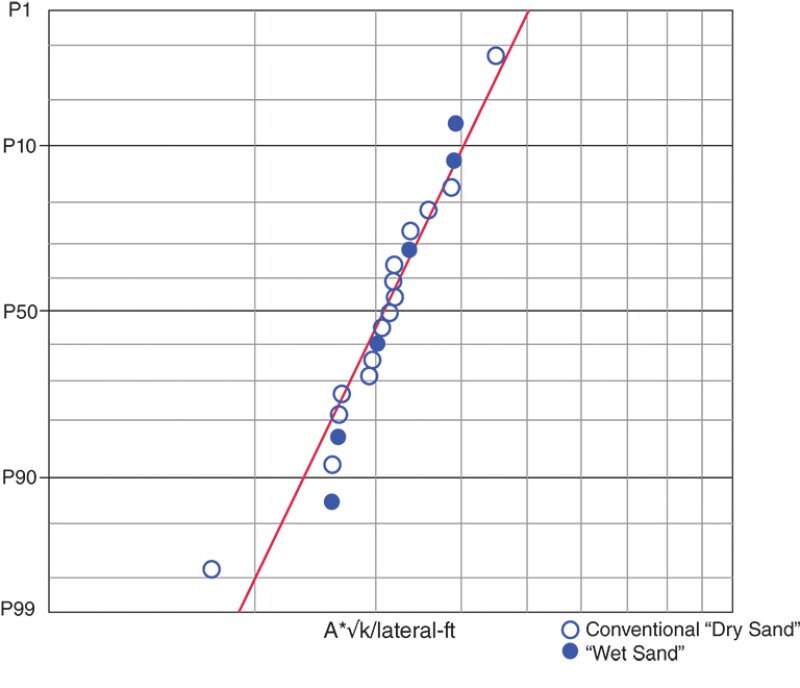

That said, the operator has drawn no conclusions on whether the extra microproppant represents anything outside of a capital savings at this point. All the wells Chesapeake has completed so far with wet sand have met or exceeded their expected initial production rates, but the operator said more production time is needed to draw conclusions on whether it is seeing improved recovery rates.