In this paper, the authors propose a new method for time-lapse-seismic surveys focused on water-injector wells. The “instantaneous 4D” (i4D) method aims to acquire dedicated high-quality 4D data with a short turnaround time at cost levels low enough to make it affordable to repeat such data-acquisition programs reasonably frequently. We have implemented the method as a variation on surveys that use ocean-bottom seismometers. We suspect that our method can also be combined with other means of seismic-data acquisition (for example, permanent reservoir-monitoring systems and vertical-seismic-profiling systems in wells).

Introduction

Time-lapse, or 4D, seismic is frequently used offshore to monitor fluid-movement processes such as waterflood or aquifer drive. These processes happen at relatively slow time scales (years). As a result, proper monitoring of these effects requires repeat surveys to be acquired every 3 to 5 years or so.

Recent examples in industry show that fast reservoir changes (months) also are taking place. The observed changes are often associated with water-injector wells. For example, one water-injection well documented in the literature produced large time-lapse signals in less than 1 year after its startup. Because of cost and other considerations, it is not feasible to repeat fieldwide 4D surveys often, nor to install permanent monitoring systems in many of those fields. Yet there is a need to monitor such phenomena more frequently and with short reaction times. This is where the authors believe that the i4D method can play an important role.

This method is not intended to replace full-field surveys. Rather, it adds small surveys more frequently in between regular full-field surveys to enable better observation of fast 4D reservoir effects along with slow changes. It can be seen as filling the gap between the current practice of infrequent full-field surveys and the installation of permanent reservoir-monitoring systems, which can be expensive.

Method

i4D seismic makes use of existing technology in a different way. There are three critical factors that underpin this method. First, it leverages the very high quality that repeat ocean-bottom seismic (OBS) surveys are able to achieve. Second, the method demonstrates scalability, which is enabled by the choice of OBS technology. While the layout and equipment of streamer surveys make it impractical and inefficient to cover anything less than a full field, a target-oriented approach is possible with OBS technology, because one can choose how many receiver node positions one wants to occupy. Third, the method employs a reduced operational footprint in the field. The downscaling involved in i4D seismic allows for combination of source arrays and node-handling facilities on a single vessel. Also, the required time in the field is much reduced in the scaled i4D-seismic solution; this provides the required flexibility to acquire data on relatively short notice and to keep costs low. To combat relatively large mobilization efforts, we have bundled a number of i4D-seismic surveys into a single pilot program executed in the Gulf of Mexico (GOM) in 2012.

Quality

The high quality of 4D data as obtained by repeat OBS surveys is found to be related to the excellent repeatability that can be achieved. Also, it is suspected that the availability of full-azimuth coverage inherent to seafloor data is another key factor in this respect.

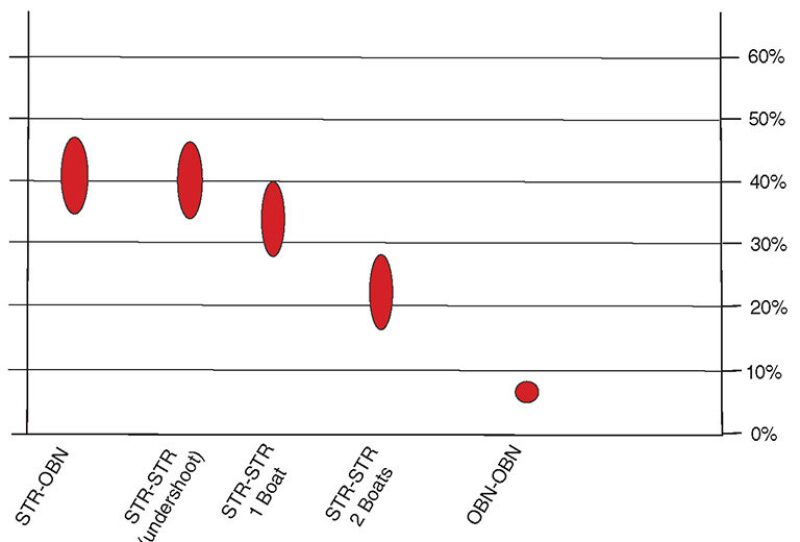

Fig. 1 summarizes the normalized root-mean-square (NRMS) noise levels that were encountered for various acquisition types in the GOM in a number of fields. While NRMS is not a perfect indicator for 4D-data quality, in the authors’ experience the general trend is valid, even if the absolute numbers for NRMS need to be treated carefully (they are dependent to some extent on 3D background geology and on choices for window length and target depth).

Note the relatively poor performance of streamer options caused by the presence of relatively large and unpredictable currents in the GOM. Streamer surveys that employ more than one vessel have been used successfully to acquire high-quality 4D data, although this comes at a considerable additional cost.

Scalability and Survey Design

If there are too few receivers, one will suffer high noise levels; too small an area will lead to an abundance of edge effects, leading to distortions at target level. Also, the so-called “sphere of influence” of injector wells needs to be considered in some detail. Careful survey design is a critical ingredient in ensuring that the identified target zones remain well-illuminated in the presence of geologic complexity and overburden distortions. Edge effects need to be avoided, and an optimal balance needs to be struck between the need to maintain data quality and the desire to contain costs.

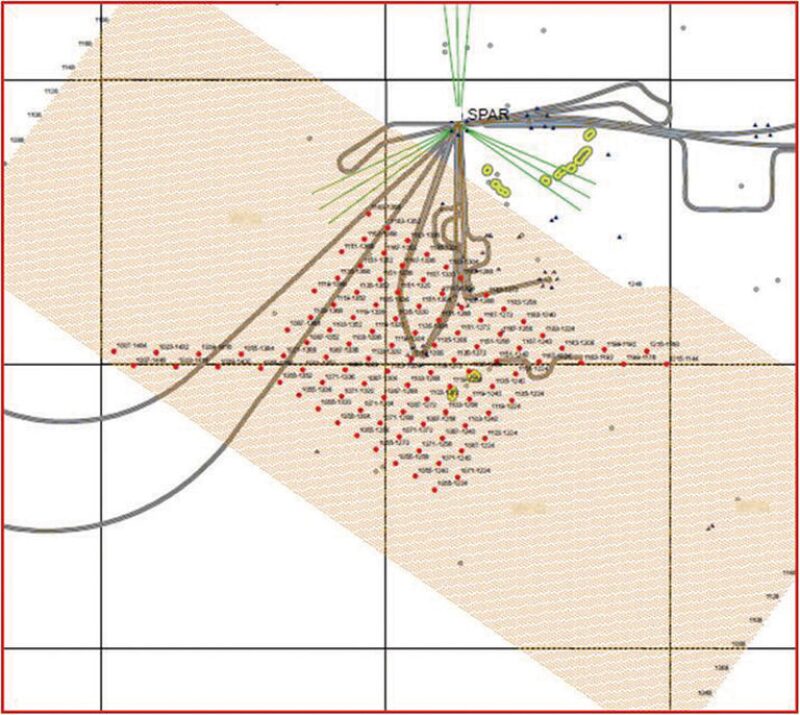

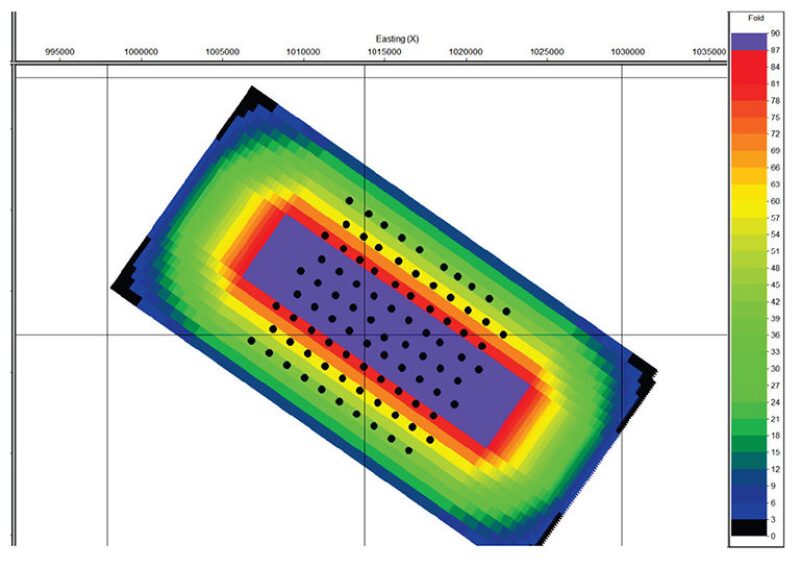

Fig. 2 shows the layout of the i4D survey across an injector well. This survey features a 400×400-m node grid in hexagonal layout in combination with a 50×50-m grid. This gives a maximum fold of 90 in 25×25-m bins (Fig. 3).

Operations and Cost

While conventional OBS crews comprise a dedicated node-handling vessel and a dedicated source vessel, the target-oriented approach of the i4D method translates into lower equipment requirements, enabling the combination of gun arrays and node-handling equipment on a single vessel. This results in a lower day rate, and this offsets the lower operational efficiency of a smaller vessel. We mobilized a dedicated i4D-seismic vessel (shown in Fig. 4), which is a new build and is outfitted for this task.

We have tested the concept in four separate surveys with a nodal footprint between 100 and 300 nodes (as opposed to numbers in excess of 1,000 nodes for regular OBS surveys). The lower equipment and effort requirements also translate into a shorter acquisition cycle, improved turnaround, and lower costs. We are able to obtain first results from seismic processing approximately 2 months after the last node is recovered from the seabed. Given that changes around injector wells can vary quickly with time, such short turnaround is important for two reasons. First, like a photograph, the shutter time needs to be much shorter than the pace of change of the subjects; otherwise, blurred images may result. Second, any local changes reveal information about the inner workings of waterflood dynamics around injector wells, and one wants to be able to respond quickly if necessary. In principle, one could deliberately change the injection characteristics of injector wells while the i4D-seismic crew is in the field to take multiple snapshots at several key moments, but this notion of “posing for the camera,” so to speak, is an area the authors have not yet explored.

In 2012, all active water-injector wells in the Shell-operated portfolio in the GOM were covered through a campaign of four i4D-seismic surveys. Initial results from seismic processing suggest to us that our i4D solution, with reduced operational complexity and cost, is successful at delivering high-quality 4D-seismic data. In one case, we observe an absence of steep dips locally, and we attribute this to the limited footprint of the method.

Conclusions

Shell has developed this technology through the execution of an integrated campaign spanning several fields in our GOM portfolio. The method enables frequent monitoring of fast reservoir changes in the offshore. With i4D seismic, we should be able to monitor reservoir integrity, optimize injection rates, and increase waterflood effectiveness and pressure maintenance. Effective monitoring prevents deferred production by improving injector reliability and efficiency; drilling slots may be used for producers rather than replacement injectors or additional injectors.

This article, written by JPT Technology Editor Chris Carpenter, contains highlights of paper IPTC 16901, “Instantaneous 4D (i4D) Seismic: An Innovative Concept To Monitor Offshore Water-Injector Wells,” by J.G.F. Stammeijer, M. Davidson, P.J. Hatchell, and J.L. Lopez, Shell, prepared for the 2013 International Petroleum Technology Conference, Beijing, 26–28 March. The paper has not been peer reviewed. Copyright 2013 International Petroleum Technology Conference. Reproduced by permission.