In a world where smartphone users chafe at 4G signals that top out at 10 million bits per second, downhole drilling data are still conveyed to surface at less than 10 bits per second.

This week, a Norwegian company rolled out the latest effort to change the status quo that depends on mud pulses and memory cards to gather downhole drilling data.

Reelwell announced it has sold its first two strings of wired pipe to Nabors Drilling, which supported the testing work that demonstrated it could reliably handle power and data along the drillstring.

The announcement by Reelwell was made at the virtual SPE/IADC International Drilling Conference, setting off a discussion about why NOV and others have been unable to create a large market for wired pipe after more than a decade of trying.

The value seems self-evident: Digital creates a huge appetite for power and the bandwidth to collect a lot of data in real time.

“We do not see how drilling automation can happen when telemetry rates to and from the bit are at the speed of Morse code,” said Trevor Burgess, a managing director for Lime Rock Partners, an investment firm backing Reelwell. He “telegraphed” the announcement at the symposium put on by the SPE Drilling Systems Automation Technical section.

Reelwell’s pipe can send data at 56 kilobytes per second and deliver 500 W of power downhole, which could allow measurement-while-drilling units (MWD) to feed more data to surface control units.

The new design is supposed to address past complaints about wired pipe. It promises to be highly reliable and does not require special assembly methods when connecting sections of pipe.

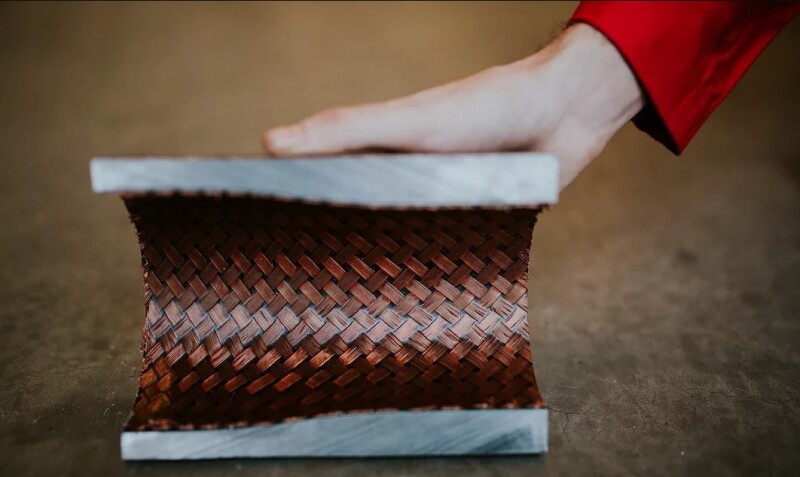

The power and data travel through more than 800 wires braided into what looks like a fabric wrapped around the drillpipe. Power and data flows from pipe to pipe via ring-shaped connectors that meet as pipes are put together.

Reelwell did not say what it costs—always an industry concern—but it points out it could save some money.

“Now we are only taking snapshots and averaging the results. You can take a cutter off your bit in 2 minutes and you can miss that,” said Ian Silvester, the chief executive officer at Reelwell.

Quicker reaction times may well be able to save the cost of replacing expensive hardware and the time lost doing it, but it is not as easy as measuring the value of a faster rate of penetration, which is near its limit on land.

The real opportunity is in the consistency of process, top-quartile performance by implementing best practices, and “avoiding train wrecks and lost time,” Silvester said.

In a virtual discussion following the symposium, others with experience in wired pipe said it is hard to know what will finally change the ways of the business.

“There has been almost zero take up on wire pipe,” said John Macpherson, senior technical advisor in drilling for Baker Hughes, who sees the value of wired pipe. “The upsides are tremendous, so I don’t understand the inertia in the industry.”

Those who have used wired pipe to better understand drilling have said the results have been eye opening.

A paper from Occidental Petroleum from the 2019 drilling conference said the added data were instrumental in a campaign to systematically reduce drilling dysfunction (SPE 194093). But the paper also reported that the lessons learned using wired pipe could be successfully transferred to rigs without it.

Reelwell’s business plan assumes that will change as drillers and their customers focus on consistently drilling more productive wells with less downtime.

With support from Nabors, Reelwell needs to be able to demonstrate that these added capabilities add value all the time.

“We believe DualLink will be an important element in the evolution of integrated drilling solutions,” said Subodh Saxena, senior vice president, Nabors Drilling Solutions, adding, “It will reduce overall well-construction costs and will enhance our automated drilling smart apps, generating smoother and more accurate wellbore trajectories, ultimately leading to increased production for our customers.”

Service companies such as Nabors are motivated to actively support developments giving them a competitive edge during what has been a protracted downturn.

The companies are trying to move away from day rates, which took another hit last year when oil prices crashed. Contractors are looking for deals that reward them for improved performance, as mentioned by Saxena, and which requires developing tools and expertise to deliver.

Collaboration will be required to change the status quo because many of the benefits cannot be realized without spending more time and money.

For example, an improved power supply means that bulky turbines and batteries which now fill much of the space in MWD units would be replaced by much smaller equipment to manage the power distribution and provide a backup.

The result could be significantly shorter-length units, or ones that use the space for equipment needed to make more and better measurements downhole.

Another possibility is the faster data link could allow new and simpler rotary-steerable tool designs because downhole processing capacity is no longer needed when it can be done on the surface. But again, redesigns would be required.

Burgess said change will pay off because “you cannot bring the drill bit to the internet if you are dependent on 40-year-old MWD technology.”

But all those changes would require customer support from operators.

Users would like wired pipe connecting the downhole and the surface, said Sven Krueger, global drilling services technology leader, Baker Hughes, adding, “But there is a challenge to overcome: Where is the return on investment?”

During the discussion Matt Isbell, senior drilling advisor for Hess, said operators will be willing to spend more for digital change if it delivers “new well designs that will mean greater recovery.”

Reelwell will be playing the role of a utility suppling bandwidth and power, depending on customers to take advantage of what it is offering and resolving long-standing problems, including questions about data ownership.

Burgess acknowledges that problem but said the industry’s motivation to change is there now. “A purely oil-well service company that just hopes for the next upcycle to solve its problems is not likely to survive,” Burgess said