What fossil fuel was to the industrial revolution, lithium is to today’s energy transition.

Often referred to as the oil of the 21st century, this strategic commodity is essential to the manufacture of batteries, from the 35- to 100-kWh type that power electric vehicles (EVs) to grid-size 100-MW (and larger) battery energy storage systems (BESS) such as those at Tesla’s Gambit Energy Storage Park near Houston, whose power capacity is among the highest in the US.

Because lithium-ion batteries charge quickly and last longer due to their higher power density, it is not surprising that as the energy transition picks up the pace, the demand for lithium is rapidly outstripping supply, leaving the industry scrambling to find new sources—whether that means opening new mines or devising new technologies to extract lithium from brines, including brines found in water produced from oil and gas operations.

In the EV arena, Deloitte forecast a 29% compound annual growth rate in EV sales over this decade, predicting that EVs will comprise 32% of new car sales by 2030 with China commanding 49% of the market, Europe holding 27%, and the US at 14%.

The US Environmental Protection Agency attributes 30% of US greenhouse-gas emissions to transportation, a fact that has prompted the automobile industry to shift into transformational mode to make this decade the tipping point when EVs become mainstream.

Catching the Vibe at CES

In her keynote at the 2022 Consumer Electronics Show (CES) in Las Vegas, Nevada, in January, General Motors CEO Mary Barra announced that in 2023, GM will launch production of its long-anticipated electric Chevrolet Silverado pickup truck, a move made possible by the company’s $35-billion investment strategy announced last summer to compete with Tesla.

GM’s investment plan through 2025 targets, among other things, “on lining” four new, US-based lithium-ion cell production plants with a combined cell production capacity of 140 GWh/year, based on the company’s proprietary Ultium platform.

Ultium Cells LLC, a joint venture with LG Energy Solution, announced in late January it would build its third plant in Lansing, Michigan. The JV is currently constructing plants in Lordstown, Ohio, and Spring Hill, Tennessee; the location of the fourth plant has yet to be announced.

Back in Las Vegas, Sony grabbed headlines at CES by reaffirming it will open its own automobile unit, Sony Mobility Inc., in the spring of 2022, and Chrysler, a part of the Netherland’s Stellanis group, treated CES visitors to a look at its first EV concept car which is planned to launch in 2025.

From that standing start, Stellanis said it expects to convert 70% of its European vehicle sales and 40% of its US sales over to the EV category by 2030.

Backing Up Power Grids the BESS Way

Then there are power grids whose reliability can be increased by storing electricity in mega-size battery farms on the good days when the sun shines and the wind blows. That way, electricity is available when the weather turns ugly as it did in Texas in February 2021, when a winter storm knocked off line nearly half of the state’s total power generation capacity.

Less than a month after the crisis, Bloomberg reported that a Tesla subsidiary, Gambit Energy Storage, was quietly completing construction of a BESS in the town of Angleton in Brazoria County, Texas. It became operational last summer with a 100-MW storage capacity.

Houston-based Plus Power, which develops utility-scale energy storage projects across the US, said it initiated the Angleton project in 2019 and sold it to Tesla in 2020. Tesla CEO Elon Musk is moving to Texas and has openly stated his intent to spin a separate grid energy storage business off Tesla, which he anticipates will be a bigger business for the company than EVs.

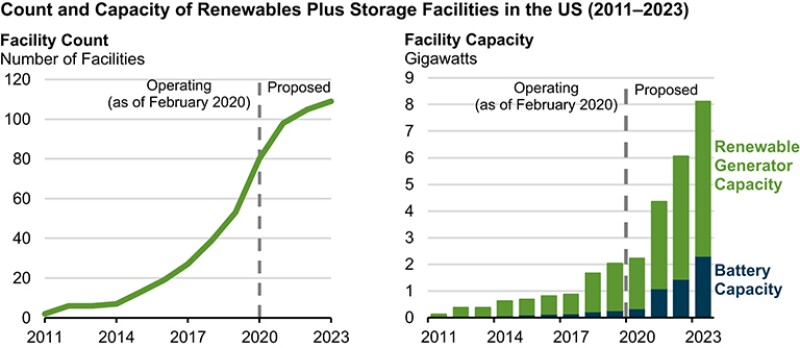

In May 2020, the US Energy Information Agency (EIA) reported that 90% of US hybrid capacity (battery storage plus renewable power generation) could be found in only nine states, and 46% of that capacity could be found in Texas.

Besides Gambit, Plus Power is promoting another 10 projects on its website, the largest of which is the 185-MW Kapolei Energy Storage on Oahu which the Hawaii Public Utilities Commission approved in May 2021; the smallest is the 10-MW Sierra project, the first large-scale battery system co-located with a biomass power plant, due to come on line in 2023.

The number of solar and wind power sites co‑located with battery storage grew from 19 in 2016 to 53 in 2019; by 2023 another 56 paired facilities will be added, according to the EIA (Fig. 1).

Too Little Lithium, Too Little Time

Lithium has been in deficit globally since 2021 when stockpiles became depleted as production was unable to keep pace with demand; this trend is expected to continue throughout 2022, S&P Global warned in a report issued in December.

Citing S&P Global Platts’ data, the report detailed the degree to which lithium prices have skyrocketed. Over the 12 months of 2021, the price of seaborne lithium carbonate rose 413%, topping $32,600/mt CIF North Asia by mid-December; lithium hydroxide prices jumped 254% over the same period to $31,900/mt CIF North Asia.

While prices of batteries essential to the production of EVs and grid-oriented storage systems have declined sharply over the past 10 years, the Japanese financial agency Nikkei Asia is predicting that battery prices will start to rise again in 2022 as lithium remains in deficit. This will cause problems for the auto industry’s EV plans and short-circuit efforts to stabilize power grids.

And the problem isn’t just about lithium, considering that other commodities used to manufacture cathodes, the most expensive part of a battery, are also under pressure. Nikkei Asia notes that the price of cobalt in fact doubled over the last year to $70,208/ton, while nickel jumped 15% to $20,045/ton in the same period.

Looking at the supply side, the US Geological Survey (USGS) estimated global lithium reserves in 2020 at about 86 million tons, of which 58% are found in three countries dubbed appropriately the “Lithium Triangle Countries” and home to some of the world’s largest salt flats: Bolivia (21 million tons), Argentina (19 million tons), and Chile (nearly 10 million tons).

Positioned fourth globally after Chile, the US claimed approximately 8 million tons in lithium resources in 2020 from continental brines, geothermal brines, hectorite (a relatively rare, naturally occurring clay), oilfield brines, and pegmatites (a type of coarse-grained crystalline igneous rock), according to USGS.

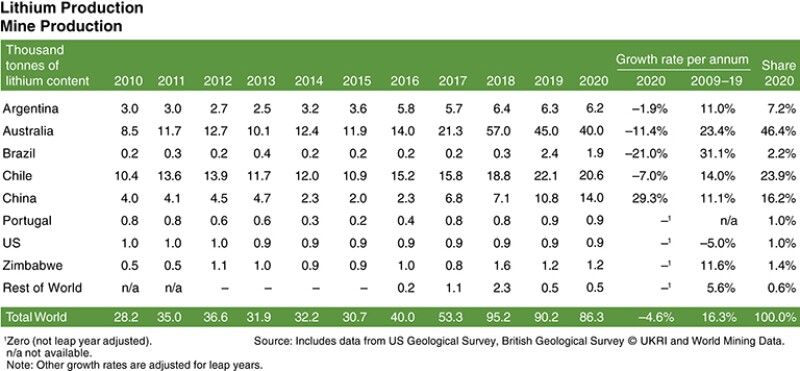

In terms of commercial production (as opposed to reserves), Australia was responsible for 46% of global lithium production in 2020 followed by Chile at 24% and China at 16%, according to the BP Statistical Review of World Energy 2021 (Fig. 2).

Australia’s production came from five mines, Chinese data were based on one mine’s activity, and Chile contributed from brine extraction, according to USGS.

Though the US currently does not mine lithium domestically, it is sitting on what is believed to be the largest lithium deposit in North America, situated in an extinct supervolcano in northern Nevada. Another lithium mining prospect lies in North Carolina.

The US may in fact have enough domestic reserves of key metals to build all the EVs that consumers want to buy, judging by a Reuters analysis which found that US mining projects could produce enough copper to build more than 6 million EVs, enough lithium to build more than 2 million EVs, and enough nickel to build more than 60,000 EVs.

Estimates quoted by Reuters were based on the volume of minerals used in making a Tesla Inc. Model 3, according to a study by Benchmark Mineral Intelligence, whose clients include the lithium-ion battery, EV, and energy-storage supply chains.

Late in the Trump administration, the US Bureau of Land Management approved a proposal from Lithium Nevada Corp., a subsidiary of Lithium Americas Corp., to start mining lithium in Thacker Pass, Nevada. The project has remained a priority of the Biden administration, which included it as part of the US president’s own strategic plan to improve the supply chain—from mining to the recycling of batteries—for strategic minerals needed to make the energy transition succeed.

But instead of breaking ground as planned in early 2022, Thacker Pass has become mired in litigation as environmentalists and local native tribes pledge to halt it.

In North Carolina, Piedmont Lithium has faced similar backlash from environmentalists and residents after applying to Gaston County authorities for a mining permit in August 2021. Piedmont and Tesla had signed a 5-year lithium supply contract supporting the project, but that contract has since been put on hold.

As a footnote, Tesla itself is pursuing a plan to extract lithium from clay deposits in Nevada—without any middleman—employing a proprietary technology it is now seeking to patent.

China’s Afghan Lithium Bonanza

China is hoping to solidify its dominance of the lithium market as it vies for the mother lode of all lithium mother lodes—in Afghanistan.

As the US military was pulling out of Kabul last summer, Chinese miners were arriving to negotiate with the Taliban to access what is believed to be the world’s largest lithium deposit—a resource valued at $1 trillion with possibly more lithium than that found in South America’s lithium triangle.

Laying claim to such a deposit on its doorstep will help China (which currently has rights to mine copper near Kabul) produce batteries at even more competitive prices for use at home and for export, considering that the alternative, importing the lithium from South America to Asia, is not economical.

China already accounts for more than 65% of global battery production and more than half of lithium chemical production, according to Nikkei Asia, which quoted a Japanese lithium trader as saying that China’s market dominance creates “geopolitical risks in the supply chain” globally.

In fact, the world’s biggest battery producer even now is China’s CATL.

Extracting Petrolithium from Produced Water

But mining isn’t everything, as specialists from the Gazprom Neft Science and Technology Center and Tyumen State University contended at the 2021 SPE Russian Petroleum Technology Conference held in virtual format from Moscow last October (SPE 206571).

In their paper, the authors made the case for extracting lithium from oilfield brines using sorption methodology, thus obtaining a higher-quality product that can be sold at a price higher than the same commodity mined from ore.

Producing lithium from brine is more capital-intensive, but the more the lithium is refined the more stable the business prospects, as sales can be made across a broader spectrum of price points. Mines, in contrast, open and shut as commodity prices rise and fall.

The authors suggest that oil and gas producers can create a new revenue stream and diversify their business models by producing lithium instead of reinjecting produced water into reservoirs. A casual internet search for “petrolithium” reveals that the Russian researchers might very well be on the right track.

The feasibility of extracting lithium from produced water is also being studied in the US. In a recent paper published in Proceedings of the National Academy of Sciences, researchers at The University of Texas at Austin and University of California, Santa Barbara, described their work to develop a way to extract lithium from contaminated water using a novel polymer membrane.

Beyond salt brines, wastewater generated in oil and gas production contains lithium but remains untapped today. The researchers said that a single week’s worth of water from hydraulic fracturing in the Eagle Ford Shale has the potential to produce enough lithium for 1.7 million smartphones or 300 electric vehicle batteries.

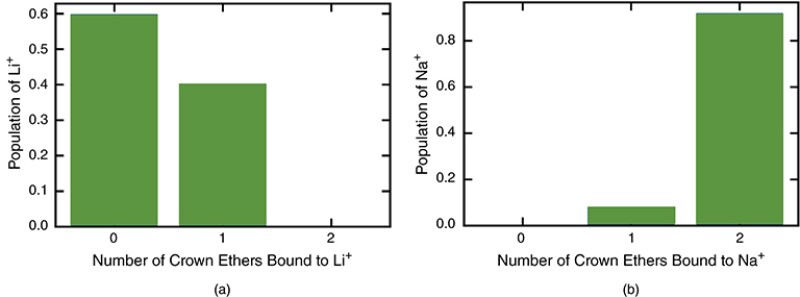

The membrane was created using crown ethers, which are ligands with chemical specificity to bind certain ions. Crown ethers had not previously been applied or studied as parts of water-treatment membranes, but they can target specific molecules in water—a functionality necessary for lithium extraction (Fig. 3).

In most polymer membranes, sodium travels through faster than lithium. However, in these new materials, lithium travels faster than sodium, which is a common contaminant in lithium-containing brines. Through computer modeling, the team concluded that sodium ions bind with the crown ethers, slowing them down, while lithium ions remain unbound, enabling them to move more quickly through the polymer.

“The study’s findings have significant implications for addressing major resource constraints for lithium, with the potential to also extract it from water generated in oil and gas production for batteries,” said Benny Freeman, a professor in the McKetta Department of Chemical Engineering at UT Austin and a coauthor of the paper.

In May 2021, the US Department of Energy’s National Renewable Energy Laboratory (NREL) published a study of the technology and economics supporting direct lithium extraction from geothermal brines, focusing on the highly toxic Salton Sea in Imperial County, southern California.

The Salton Sea possesses the most lithium‑rich geothermal brines in the US, and the NREL noted that three operators—Energy Source, Controlled Thermal Resources, and Berkshire Hathaway Energy—will test the feasibility of extracting lithium using ion-exchange sorbents and research how best to reduce their production costs and ride the upside of the lithium revolution. JPT

For Further Reading

SPE 206571 Recovery of Lithium from Associated Water for Oil and Gas Deposits by A.Y. Gavrilov, A.A. Bandaletova, and N.A. Devleshova, Gazprom Neft Science & Technology Center; E.V. Galin, Gazprom Neft; and M.O. Pisarev and D.A. Liss, Tyumen State University.

NREL/TP-5700-79178 Techno-Economic Analysis of Lithium Extraction From Geothermal Brines by I. Warren, National Renewable Energy Laboratory.

Engineering Li/Na Selectivity in 12-Crown-4–Functionalized Polymer Membranes by S.J. Warnock, University of California; R. Sujanani and E.S. Zofchak, The University of Texas at Austin, et al. Proceedings of the National Academy of Sciences.