Since the late 1930s, the offshore industry has moved from installing the first offshore platform in 14 ft of water to the ultradeepwater 20K era.

Advances in seismic, drilling, and development technologies all helped move the industry from shallow waters to ultradeepwaters, from lower-pressure reservoirs to high-pressure/high-temperature (HP/HT) reservoirs, and beyond known hydrocarbon areas like the Gulf of Mexico (GOM) into frontier regions, like Guyana.

Brent Gros, vice president of Chevron’s GOM business unit, told JPT there is a stark difference between the GOM of today and how it was when he first started working in the area 26 years ago. Now, he said, operating further from land in water depths of 4,000 to 7,000 ft is the norm.

“We’re not really taking crew boats to those platforms, given the distance from shore. We operate as well at much higher pressures,” he said.

Jayme Meier, ExxonMobil’s vice president of deepwater project delivery, echoed that sentiment.

At the dawn of the offshore era, “anything that was in any amount of water was, by definition, deep water, because it was as far as you could go,” she told JPT. “And we are now at the stage where we are routinely doing things that are in 2000 m (6,560 ft) of water or more, and we continue to press boundaries and technical limits to be able to move further out in water depth.”

As such, she said, the fundamental definition of deep water has shifted in the past quarter century.

Where To Drill?

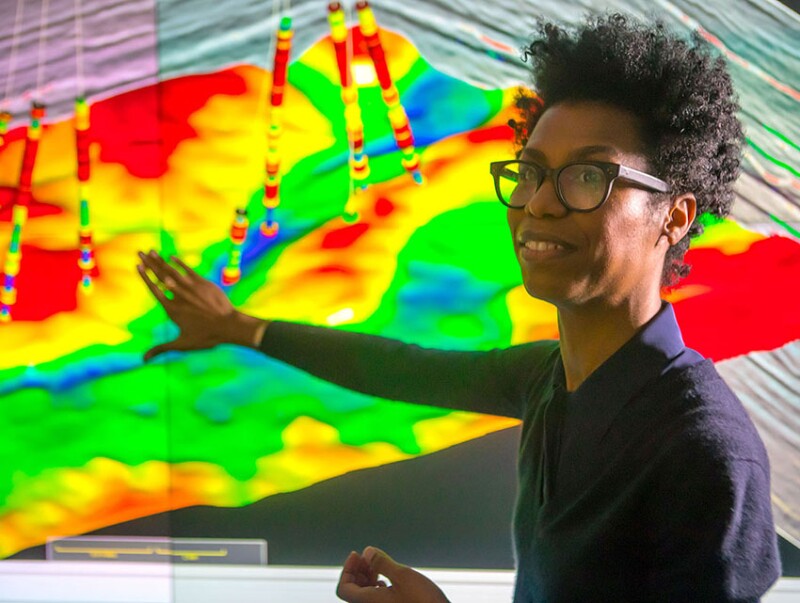

“To find oil and gas resources, we rely on seismic, and we’ve seen huge advancements in seismic over the past 25 years,” Gros said.

3D seismic technology, pioneered half a century ago, sharpened the view into the world’s reservoirs, and new seismic processing methods have helped identify new opportunities.

“Now we have ocean-bottom node surveys, which essentially take a lot of the noise out of surveys, allowing us to image deeper with a clearer image. We also have four-dimensional seismic, which helps us understand the performance of reservoirs through time,” he said. “If you compare the seismic capability today to what we had in the past, it’s like seeing the world with a new pair of glasses, and it really helps us understand potential prospects in a more-complex geological setting and pursue those opportunities in deeper water and deeper horizons than we previously would have been able to.”

Deepwater Challenges

Moving into ever deeper waters requires more tech and more-capable drilling rigs.

It also requires precision, Meier noted.

“Technology allows us to position a floating rig on the surface of the ocean. It’s got to be able to drill at very precise angles and precise locations, and significant extensions of technology were needed to enable that to happen. We’re at the point now where we’re even doing multizone completions on our wells in deep water,” she said.

She called deepwater “by far the most exciting space” to work in. It requires planning and designing for facilities that must withstand intense, harsh, and constantly changing conditions throughout its lifetime.

“You are floating on a surface, and you have to be able to pinpoint exactly where you’re going to land subsea hardware, exactly where you’re going to moor an FPSO and hit target boxes that are a few feet by a few feet, and they’re 6,000 ft below you,” she said. “It is the most exciting thing that I’ve ever been involved in. And it involves technology, technical know-how, and an ability to really plan the base plan and the contingency plan.”

The higher-pressure reservoirs the industry is encountering require equipment adequate for the task.

Lars Herbst, who retired from the post of Bureau of Safety and Environmental Enforcement’s (BSEE) GOM regional director in late 2021, told JPT that early in his career, much of the equipment was not ready for HP/HT operations.

Once equipment rated for 10,000-psi operations was introduced, “it quickly moved to 15,000 psi, and stayed that way until just a few years back, when the 20,000-psi BOP (blowout preventer) equipment and wellheads and things like that were introduced,” he said. “That’s a big improvement on the drilling side.”

And Chevron helped hasten the development of 20K capabilities so it could move forward with its Anchor project, which delivered first oil 11 August in the GOM with production flowing to a semisubmsersible moored in 5,000-ft water depth in Green Canyon Block 763.

Transocean’s 8th-generation Deepwater Atlas and Deepwater Titan drillships, rated to work in 12,000-ft water depths and drill to 40,000-ft depths, entered operations in 2022 and 2023, respectively. The Atlas, initially rated for 15,000-psi operations but later upgraded for 20,000-psi operations, went under contract to Beacon Offshore Energy for work in the ultra-HP/HT Shenandoah development in the Walker Ridge area of the GOM, and the 20,000-psi-rated Titan started operations on Chevron’s Anchor development.

The Titan “can operate with a 3-million-pound hookload. To be able to lift well equipment with thicker wall thickness and heavier weights requires rigs that are more capable,” Gros said.

He said trailblazing 20K reservoir activity took fortitude.

“Industry previously said, ‘This is something we can’t access,’ and it takes some fortitude to start down the journey of developing the technology,” Gros said. “Just a few years ago, there wasn’t a rig capable of doing this. There wasn’t a BOP. There weren’t regulations to support the development. And so, it takes a lot of work to unlock this, and we’re now poised to really benefit from it.”

Tie It Back

As the industry ventured out into the GOM, how it approached projects changed dramatically, Gros said. Historically, shelf projects tended to spread out.

“There was a lot of infrastructure spread,” he said. “Now that we’re operating in deep water, the infrastructure is much more expensive, and we can’t have a platform near every group of wells, so we tend to rely on longer distance tie backs.”

Chevron plans to bring its Ballymore subsea tieback, sanctioned in May 2022, online in 2025, with production from the field in Mississippi Canyon Block 607 in around 6,600 ft flowing through a 3-mile tieback to the Blind Faith production semisubmsersible in Mississippi Canyon Block 650.

“We have ample infrastructure as an industry in the Gulf of Mexico, and so how we leverage other opportunities to fill that infrastructure is going to be a key part of being efficient,” Gros said.

Chevron is drilling three wells into the Norphlet formations, with the wells expected to produce up to 75,000 BOPD to the Blind Faith production facility.

And while the Ballymore tieback is relatively close, the industry can step out much further, made possible through improvements in tech such as subsea boosters and pumps and communication capabilities.

“It’s like its own little ecosystem, the subsea development,” Gros said. “You can’t even see the next facility, and everything is below the sea.”

There have also been advances in control systems that enable chemical injection from a distance, he noted.

Herbst, too, gave the nod to control systems as an enabler. SCADA technology’s ability has improved to control systems “much better than they could even 25 years ago,” he said.

On the production side, he said, overall improvement in electronics has made a major difference, as has the move from all-hydraulic systems to electro-hydraulic or all-electric.

“That was absolutely necessary for the subsea development to really occur,” Herbst said.

Sensors and transmitters, too, have improved.

“Moving into deep water really could not have occurred without the advancement in that technology,” he said. “I think there’s still quite a bit of room for advancement in that area, digitalization of a lot of the processes and measurements.”

None of the deepwater projects would be possible, though, without subsea hardware.

“Just the idea that you build something once, you put it down on the ocean floor, and it’s going to function—a tree, a manifold, a valve, an umbilical, a subsea processing kit—for the life of an asset, or very close to that, is pretty phenomenal,” Meier said. “Those are very carefully designed things that have become more robust over time.”

However, she said, there is room for improvement when it comes to subsea processing and compression.

“I think advances are needed in subsea processing. More subsea hardware to do more work on the subsea floor and less on top,” Meier said.

Expanded Frontiers

One of the larger offshore frontier regions to open up in the past 25 years is Guyana, where ExxonMobil has three FPSOs in production, three FPSO-based projects underway, and several more projects in early development.

“There’s a whole long story behind how we found it. It was touch and go for a while, but after we found it, we were able to deliver our first FPSO within 5 years from discovery to startup,” Meier said.

And while the supermajor has a series of FPSOs planned for its Stabroek block offshore Guyana, they’re not cookie-cutter replicas.

“We’re working in a mindset that says we’re going to use the best we have available today, and then we’re going to learn as we go,” she said.

The objective is that as soon as the project team learns something, it determines how to best apply that knowledge to the next project, so each project continues to get better. “You should not make the same mistake twice. You can learn from it once you apply those learnings, and then you move forward,” Meier said.

For example, she said, the first FPSOs deployed offshore Guyana used industry-available technology to reduce greenhouse gas (GHG) emissions. For the fourth unit, ExxonMobil was able to incorporate waste-heat recovery units into the compact FPSO layout for the Yellowtail field. For the Uaru field FPSO, ExxonMobil added combined-cycle technology, which uses steam-turbine generators to improve thermal efficiency and reduce GHG emissions. It will be only the second application of the technology, Meier said, and it is a complicated addition because of the interdependencies of power generation and processing.

Rather than repeating that on the next FPSO, ExxonMobil sought out a different approach.

“We challenged ourselves on the sixth one and said, ‘Okay, what else can we do to get to that same GHG footprint?’ What technical solutions can we either adopt, adapt, or make ourselves to get to the same output?” she said.

Instead of using combined-cycle technology to get to the desired GHG level, the operator adopted a number of other technologies for the Whiptail field FPSO, she said. A deepsea water intake hose pulls deeper and colder water from the sea to help with cooling at the surface thereby reducing pump and compressor duty.

ExxonMobil also opted to step down the arrival pressure of the fluids at the FPSO to reduce wall‑pipe thickness and compression requirements. By combining different technologies, she said, it was possible to achieve the same outcome without using the complex combined-cycle approach.

“We’re seeing an evolution,” she said.

And pulling together each of these FPSO projects is a study in choreography.

“We have stuff in 26 countries that is coming together into this final campaign for each project, where every single thing has to come together at that one site,” Meier said. “This is a place where technology capability, project management, and wells, execution, performance all have to come together.”

Safety Focus

One of the biggest concerns about working in deep water is doing so safely. On 20 April 2010, Transocean’s Deepwater Horizon rig exploded while drilling BP’s Macondo prospect in the GOM, killing 11 and leading to the largest marine oil spill in the industry’s history.

“It was always thought that with the Deepwater Horizon, there was a large company involved there, and they had the competency and the depth within their company to respond to it,” Herbst said. “If that was a smaller company, you know, not really sure how that response would have gone.”

Herbst called the explosion a black swan incident. There was “a very low probability of something like that happening, but the consequences, obviously, were so high,” he said. “It’s always thought the BOP stack could handle it, could shut it in through various means of shut-in even after evacuation of the rig.”

The well released about 4 million bbl of oil over the course of 87 days until it was finally shut in. The Macondo explosion led to a series of safety measures, including the requirement for an operator to be able to cap a well if there’s a blowout. “Advancements in well capping for wells that do blow out, the well capping, and all the equipment associated with that was critical to get back to drilling in deep water again,” Herbst said.

The Marine Well Containment Company (MWCC) and HWCG LLC developed capping stacks that could be rapidly deployed in the event of another deepwater blowout. The industry, Herbst said, now has a solution that allows drilling with the confidence “that if there was a recurrence of an incident like that, it would not go on for 87 days.”

Over the years, BSEE has carried out unannounced drills to test how companies respond in the face of an incident. Herbst added that these drills resulted in capping stacks being transported and installed in less than 10 days.

Gros said Chevron did extensive testing to ensure the capping tech could function in 20,000‑psi conditions, and, separately, BSEE conducted an unannounced drill in May 2023 to test Chevron, the industry, and MWCC’s capability to respond to a deepwater well blowout. Chevron is one of 10 operators that comprise MWCC.

“We actually did a 5-day exercise. Chevron led a team where we deployed and installed a capping stack in 6,200 feet of water,” he said. “It was a simulated event, but it was our regulators wanting to ensure the capability of the industry to respond.”

During the drill, a remotely operated vehicle (ROV) closed 10 valves to shut in a simulated well.

“BSEE said at the conclusion that it was just a remarkable achievement. It’s a milestone for containment response,” Gros said.

He said response is one layer of keeping things safe, but things like safety systems are preventative. “When a piece of equipment failed, we would learn about it as it had the problem,” he said.

Now, sensors are alerting the industry to potential trouble. “We have sensors that start to predict, ‘Hey, this is trending.’ Maybe temperatures are starting to rise, or vibration is starting to increase, so we can start to plan our maintenance better,” he said. “Cars do the same thing. You now get a low-air-pressure warning. You don’t feel the flat tire, you get a little warning that says, ‘Hey, your tire’s starting to lose some pressure.’”

Gros expects the industry to continue innovating ways that sensors can help improve safety, such as leveraging camera technology to help prevent people from being in the way of heavy lifts.

Herbst said BOP health monitoring systems, which look at the time to failure on BOP equipment and systems, have advanced. “That actually led to BSEE being able to move to a 21-day BOP test cycle, which a lot of the world had already moved to without the advancement in technology,” he said.

Automation, such as pipe-handling systems, has also helped make the industry safer, Herbst said. “The rig-floor automation, the pipe-handling systems have advanced quite a bit,” he said. “There were learning curves with all of this technology that’s introduced, but I think ultimately that’s made the rig floor a safer place to work for those on the drilling crew.”

Looking Forward

Looking forward, Herbst said he expects technology to continue to evolve and enable offshore operations. “Technology is great, but there’s always a concern over serial No. 1 technology coming out and ensuring that the safety is not compromised,” he said.

Artificial intelligence (AI) will likely play a role going forward, he added.

Herbst also urged companies not to let the industry’s up and down cycles affect research efforts. “The up and down cycles of oil and gas are not very helpful toward advancing safety,” he said. “I always see research drop off when there’s more of a bust cycle going on. But I think that research is key to keeping up with advancements in safety.”

Gros said he believes the GOM in 25 years will look different from today, especially if one considers history to be a guide. “A decade ago, people thought 20,000 psi wasn’t possible, and just this year, we’ve completed the world’s first 20,000‑psi subsea well that will unlock new opportunities,” he said. “There’s lots of prospects that rely on that technology, and we’ve unlocked the first in the world.”

Subsea tiebacks will get longer, he said, and companies will increase their reliance on AI-based technology as the industry continues to focus on efficiency. “I think you’ll see the role of data, the role of technology, and AI helping us figure out the next iteration for the Gulf of Mexico,” Gros said.

Meier said she expects future developments to require fewer people, which would change how facilities are created. People offshore require rescue crafts, blast walls, and other equipment intended to save lives. While fully unmanned facilities are a stretch, she said the company has been working with contractors on ways to minimize the number of offshore personnel required for facilities.

“Are there bite-sized pieces you could take off that would help prove out the concept?” she asked. “If you could do something that had less need for people to manage it day to day and more remote operations, that would be a significant benefit in terms of what you design and how you operate it, and the cost structure for both.”

Meier said the expansion of the industry into frontier basins is exciting. “While we know where the basins are in the world today, if you were able to go even deeper, where would those next basins be? Because if we think ahead to the next 25 or maybe 50 years, it may be that we’re in waters our current technology won’t let us be in today,” she said.