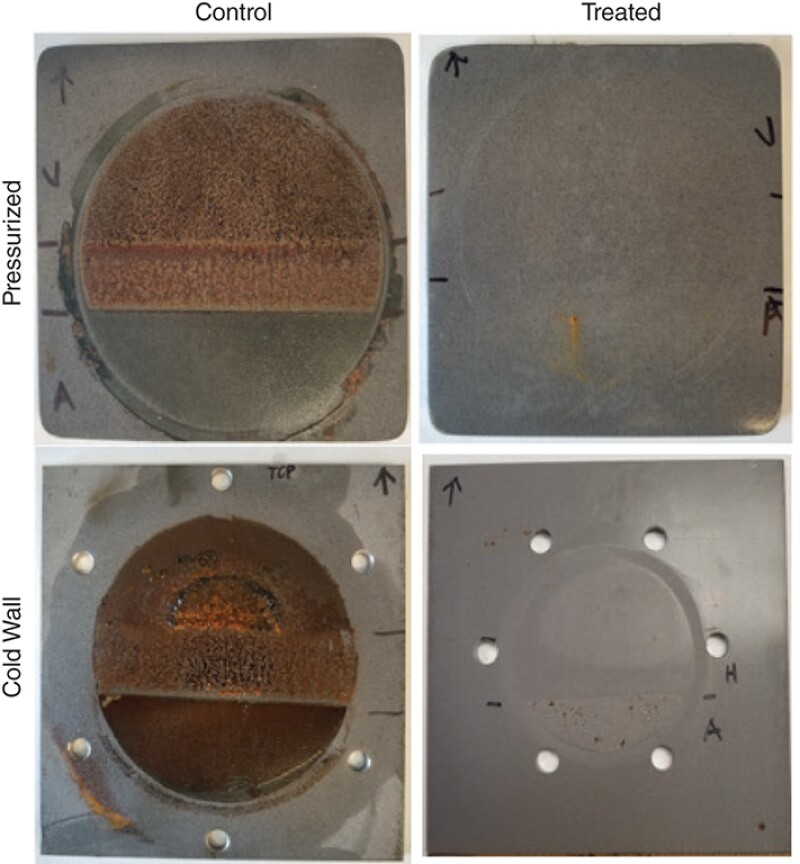

Gas hydrates, waxes, and asphaltenes represent significant flow-assurance challenges, especially in subsea lines where treatment options can be limited. As an alternative to constant chemical injection or thermodynamic controls such as insulation or heating, a robust omniphobic surface treatment (OST) material has been developed that has been shown in previous studies to reduce the adhesion of flow-assurance solids significantly, resulting in lower risk for deposition and plugging by gas hydrates, waxes, and asphaltenes.

Introduction

While laboratory-scale and mid-scale experiments have shown the OST to be effective for a range of solids-deposition scenarios, full-scale field trials require additional information to test new technologies and validate that small-scale data are applicable for deployment activities. In this work, simulations were performed that took parametric data from laboratory-scale results and applied them to a full-scale pipeline. Additionally, laboratory-scale survivability tests under a range of thermodynamic and chemical conditions were conducted, extending the range of conditions for which the surface treatment has been validated.