The Offshore Technology Conference (OTC) selected 12 new technologies for its 2016 Spotlight on New Technology awards. The annual awards program recognizes innovative technologies and allows for companies to show the latest advances in offshore exploration and production.

Award recipients were chosen based on the following criteria:

- The technology must be less than 2 years old, offered to the marketplace less than 2 years prior to the award application date. If previously advertised at OTC, it must not have been displayed at more than one conference. The technology must be original and groundbreaking, and must not infringe on any known patents.

- The technology must be proven, either through full-scale application or successful prototype testing.

- The technology must have a broad interest and appeal for the industry.

- The technology must provide significant benefits beyond existing technologies. Environmental impact is an important judging criterion.

OTC also awarded a Spotlight on New Technology Small Business Award for companies with fewer than 300 employees.

AWARD RECIPIENTS (listed alphabetically)

AFGlobal Corporation

Riser Gas Handling System

AFGlobal’s next-generation riser gas handling (RGH) system features a unique, purpose-built design that offers the simplicity, flexibility, and reliability required to efficiently mitigate gas for dynamically positioned or moored rigs. The RGH system handles retrofits and newbuilds, using specialty riser joints and equipment—all of which are transparent to rig processes.

Baker Hughes

Integrity eXplorer Cement Evaluation Service

The Integrity eXplorer cement evaluation service sets a new standard for cement evaluation by directly measuring the cement strength with its unique electromagnetic-acoustic transducers sensor technology. This technique of verifying zonal isolation gives operators the confidence they need to make critical well-integrity decisions.

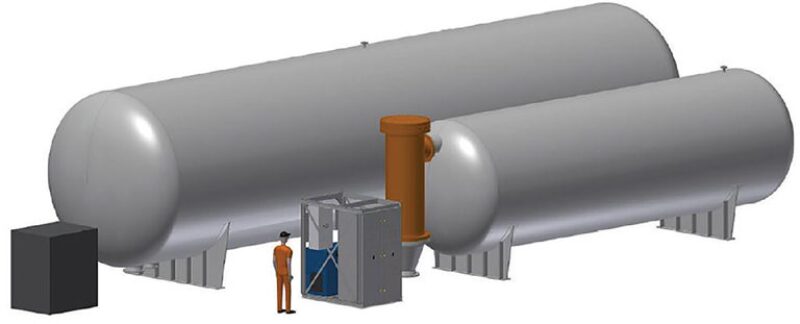

FMC Technologies

InLine ElectroCoalescer

MC Technologies’ InLine ElectroCoalescer enables efficient oil/water separation and helps maximize deepwater production of medium and heavy oil. This compact, pipe-based technology uses a high-frequency, alternating current with high voltage to polarize, coalesce, and enlarge water droplets, which can then be separated much faster in the downstream separation equipment.

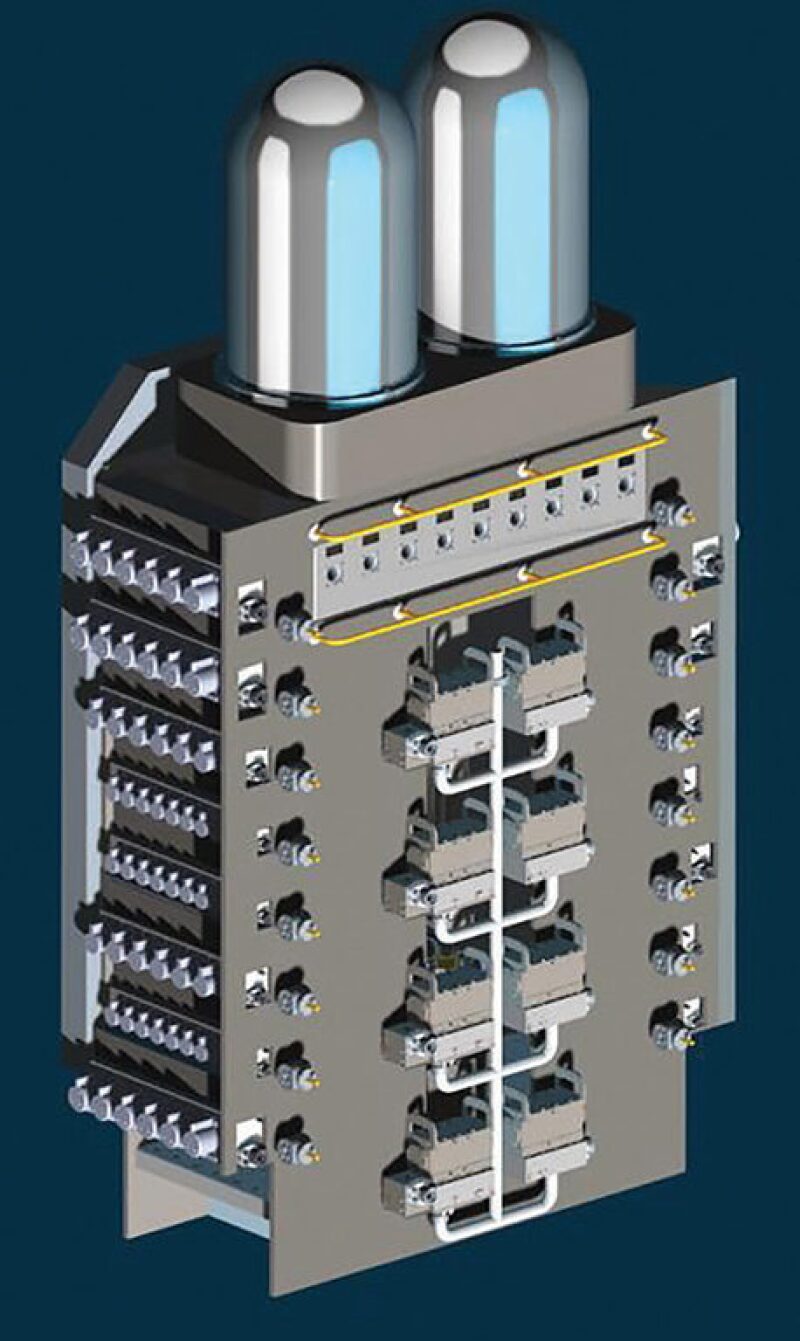

GE Oil & Gas

SeaPrime I Subsea MUX BOP Control System

The GE SeaPrime I Subsea MUX BOP control system allows drilling contractors to continue drilling if components of one pod fail. This new design simplifies access to critical components, utilizes only two pods, and re-routes failed functions within a pod to deliver three times more availability without increasing maintenance.

Halliburton

BaraLogix Density and Rheology Unit

The BaraLogix density and rheology unit (DRU) is an autonomous, automated device that allows real-time measurements of fluid density and rheology, combined with trending analysis visible to the well construction team. The BaraLogix DRU can help reduce risk, increase efficiency, and communicate drilling performance in real time.

Lankhorst Ropes

LankoDeep—Soft Rope System

The Soft Rope System is a collaboration between Lankhorst Ropes, Deep Tek, and DSM Dyneema. Capable of handling heavy loads at water depths of more than 3000 m, the system comprises Lankhorst Ropes’ LankoDeep rope, DSM Dyneema’s synthetic filament and proprietary rope coating, and an Active Heave Compensation drum winch system from Deep Tek.

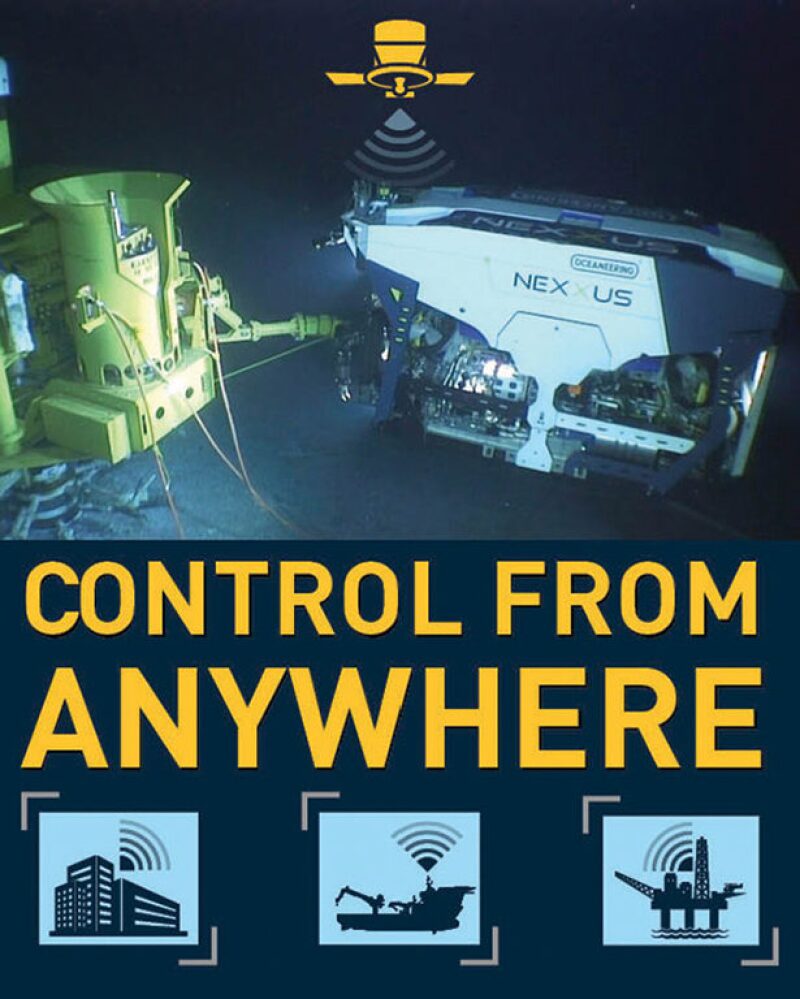

Oceaneering International

Remote Piloting and Automated Control Technology

Oceaneering’s Remote Piloting and Automated Control Technology (RPACT) improves operational efficiency. Subject matter experts or remotely operated vehicle (ROV) pilots can establish ROV control through a satellite or wireless network link to support operations at a remote work site. RPACT diminishes operational and environmental risk while reducing potential damage to tooling, manipulators, and subsea assets.

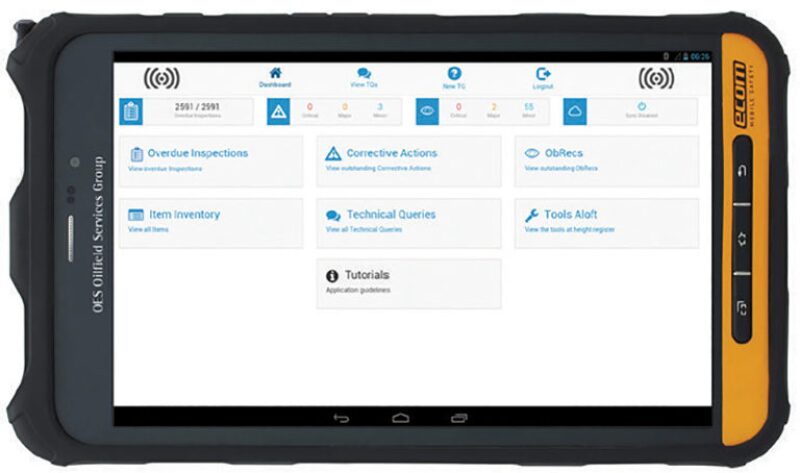

OES Oilfield Services Group

Dropped Object Prevention Program

The Dropped Object Prevention Program is a technologically innovative tablet-based, four-stage program that evaluates each rigsite’s ability to control, implement, and mitigate dropped objects. Using this information, a bespoke awareness package is created and delivered to all personnel on the rig in the form of classroom and on-site, hands-on training.

OneSubsea

OneSubsea AquaWatcher Water Analysis Sensor

The OneSubsea AquaWatcher water analysis sensor uniquely detects minuscule quantities of water in multiphase and wet-gas flows, and determines the salinity of that water. The patent-pending technology can also measure the concentration of chemicals in water to determine accurate dosage requirements, thus enabling significant risk reduction and reduced costs.

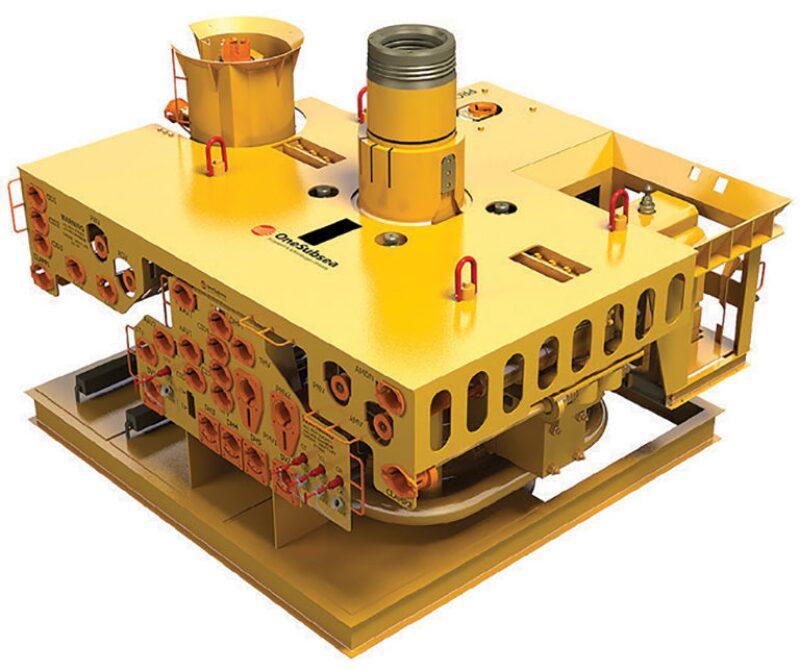

OneSubsea

OneSubsea HyFleX Subsea Tree System

The OneSubsea HyFleX subsea tree system provides the benefits of both vertical and horizontal conventional trees. Designed so the tubing hanger and tree can be installed and recovered independently of each other, it provides functional flexibility and the ability to batch-set wells, providing risk mitigation and significant cost savings in field development and over the life of the field.

SkoFlo Industries

Subsea Back Pressure Regulator Valve

SkoFlo subsea back pressure regulators (BPRs) are antisiphoning, self-regulating devices that create back pressure in chemical injection lines to prevent uncontrolled delivery of chemicals into production wells. BPRs prevent chemicals from draining into injection points when a chemical hydrostatic head exceeds injection pressure and production wells become subambient.

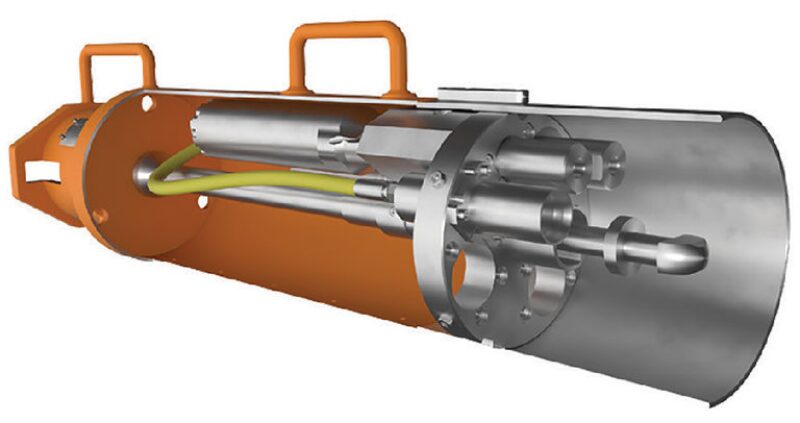

Teledyne Oil & Gas

Electrical Optical Flying Lead

The Electrical Optical Flying Lead (EOFL) features a hybrid wet-mate connector and an electrical wet-mate connector on either end of a jumper assembly, with a qualified electrical/optical converter integrated into the pressure-balanced, oil-filled hose. Including the EOFL in a data transmission network can allow for greater field architecture flexibility at a lower cost.

Small Business Award Winner

Barge Master

Barge Master T40

The BM-T40 motion-compensated crane enables safe lifting from a moving vessel to an offshore installation. It eliminates motions at the base of the crane and allows work to continue safely in higher sea states, avoiding the need for platform cranes and reducing costs significantly.