Operators are intrinsically reticent to share any information with each other in a world where their competitive advantage underpins their existence. It is, after all, the nature of capitalism.

Decommissioning, though, is decidedly anti-capitalist from an operator’s perspective. There is no money to be made, and it is all cost, something offshore operators are less equipped to bear since the commodity price collapse of 2014–16.

With that in mind, the Plugging and Abandonment Collaborative Environment (PACE) network was created to bring together operators—as well as service providers and technology firms—to share P&A knowledge on global regulations, technical challenges, emerging technology, and operational best practices.

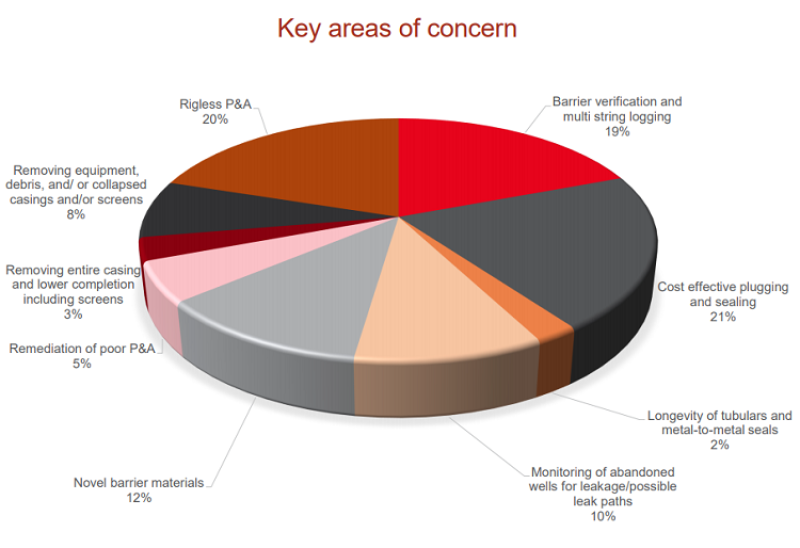

OTM Consulting began the initiative after conducting a survey of 19 operators and 27 service companies that identified cost-effective plugging and sealing, rigless P&A, and barrier verification and multistring logging as the most pressing topics in the space. PACE hopes to eventually launch joint industry projects centered on developing and testing new technologies.

“In decommissioning, a lot of the barriers between operators are not there because we are not talking about E&P,” said Chuck Greer, well abandonment adviser of PACE member Chevron, at DecomWorld’s Decommissioning and Abandonment Summit 2018 in Houston. “We’re not talking about, ‘Well, if I tell you, you might make more oil than I do.’ We all see decommissioning as a cost. So all we want know what is the cheapest way we can do it and do it right.”

OTM Consulting estimates that P&A accounts for up to 40% of total decommissioning costs for some operators.

John Hand, ConocoPhillips technology manager, said, “When it comes to plugging and abandonment, we are very open to share solutions and share opportunities, and the first reason behind that is that if one of us fails badly, then it impacts all of us.” He cited the 2010 Macondo deepwater well blowout and oil spill as an example of an incident that served as a major blight on all segments of the industry.

Overall P&A quality, including understanding of existing barrier quality, “has to be addressed because probably the only thing more costly than the initial operation is the fact that I have to go back and do it again,” said Douglas Zimpfer, Shell wells technology team lead. Greer added that leadership teams “never remember all the wells that went well, but they can name almost every disaster you had.”

Global uniformity on P&A issues is lacking. Internationally recognized standards do not exist, regulations vary by country, and, in many cases, rules dictating P&A activity were prescribed during previous generations of technology. Proving that new technology complies with regulations is expensive, especially for a single operator.

Hand said a key element of PACE is that it enables operators and service providers, when developing a new solution, to approach regulators as a team with the same objectives and data, which is “going to be a lot more effective” and save individual operators “a lot of time.”

Operator-Service Provider Dialogue

PACE also creates a dialogue between operators and service providers outside of the familiar client-customer context that can sometimes become adversarial. Operators can inform service providers and technology firms of their common P&A pain points and needs, while service providers and technology firms can update operators on their advancements in the space.

“As a service provider, if you go to one operator and you ask him what he needs, and then you go to another operator, they’re going to tell you something very different,” Hand said. One technology or one version of a technology does not fit all problems or provide solutions, he emphasized. Zimpfer believes that service companies and technology firms that develop technology for a wide spectrum of issues “actually have a chance to see their technology become successful” as opposed to merely developing it as a solution for a single problem.

Noting there is a range of suppliers in terms of scope and scale, Hand said PACE offers an opportunity for the smaller companies to nurture innovation. “The two guys who are in their garage in Manchester working on this really cool tool—they have an opportunity to be able to get in front of operators and get in front of other service companies as well” to promote understanding of the tool’s application and promote possible further development.

Access to a captive group of collaborating operators also could make it easier for service companies to find those willing to take part in field trials of new technologies, data of which could be shared among PACE operators.

Zimpfer noted, however, that forums are conducted in a way that preserves competition among service providers. For example, one supplier can present a solution to all of the operators, or a technology firm can talk to the service companies. “So we’re also trying to address and create those opportunities where you can share, but only at the level you want to share.”

Hand believes PACE is starting to break down barriers between service companies and operators and build trust between the parties, but there is still is a ways to go. “With regards to technology development and brining things to market, we’re still at the point where we’re working individually for the most part.” While a year from now he would like to be able present new technologies that have resulted from the collaborative effort, “we’re not really at that point yet.” Operators are nonetheless beginning to think differently about the process, which is a critical first step, he said.