Delfin Midstream began its cooperation with Samsung Heavy Industries (SHI) and Black & Veatch in Q4 2018 and completed a pre-front-end engineering and design (pre-FEED) study for a newbuild FLNG vessel in the first half of 2019. The parties have also been developing terms for a lump-sum, turnkey engineering, procurement, construction, installation, and commissioning (LSTK EPCIC) contract.

On 29 October, Delfin announced it has entered into new agreements for front-end design and engineering work with SHI and Black & Veatch. The partners are on track for completion of the engineering, including a fully termed LSTK EPCIC, by the middle of 2020 for the Delfin LNG project, which will include newbuild FLNG vessels.

Delfin said many land-based LNG export projects seek economies of scale to lower their costs by developing 10–20+ mtpa projects. By re-purposing existing offshore pipelines and building the FLNG vessels at Asian shipyards, Delfin is aiming for total capital costs around $500–550/tpa for just 3.5-mtpa-capacity FLNG vessels.

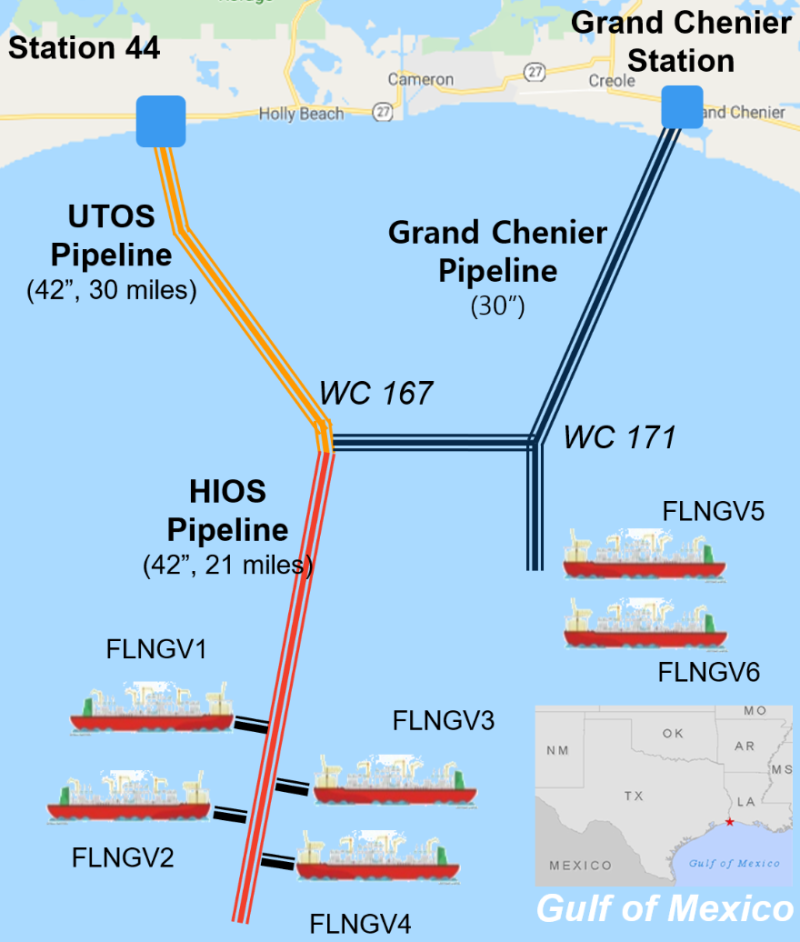

Delfin’s existing offshore pipelines connect directly to the network of onshore pipeline systems, with supply capacity for the first 2–3 FLNG vessels.

With four FLNG vessel slots at the Delfin project for a total of 13 mtpa of LNG export, and with up to 8-mtpa expansion potential with the Avocet project, Delfin said it offers large-scale LNG production at the bottom end of the cost curve.

The company expects to reach FID in 2020.

Dudley Poston, CEO of Delfin, said in a press release, “The two most important innovations of the last 20 years in the global gas market have been the shale-gas revolution and the emergence of floating LNG technologies for regasification and liquefaction. Delfin combines these two innovations to offer the LNG market a low-cost, simple, and flexible LNG supply solution.”